Device and method for recovering real wax anti-printing fabric wax based on hot water hot wax treatment

A technology of wax treatment and hot water, which is applied in the field of wax recovery equipment, can solve the problems of low recovery rate, high recovery cost, affecting performance, etc., and achieve the effect of small consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

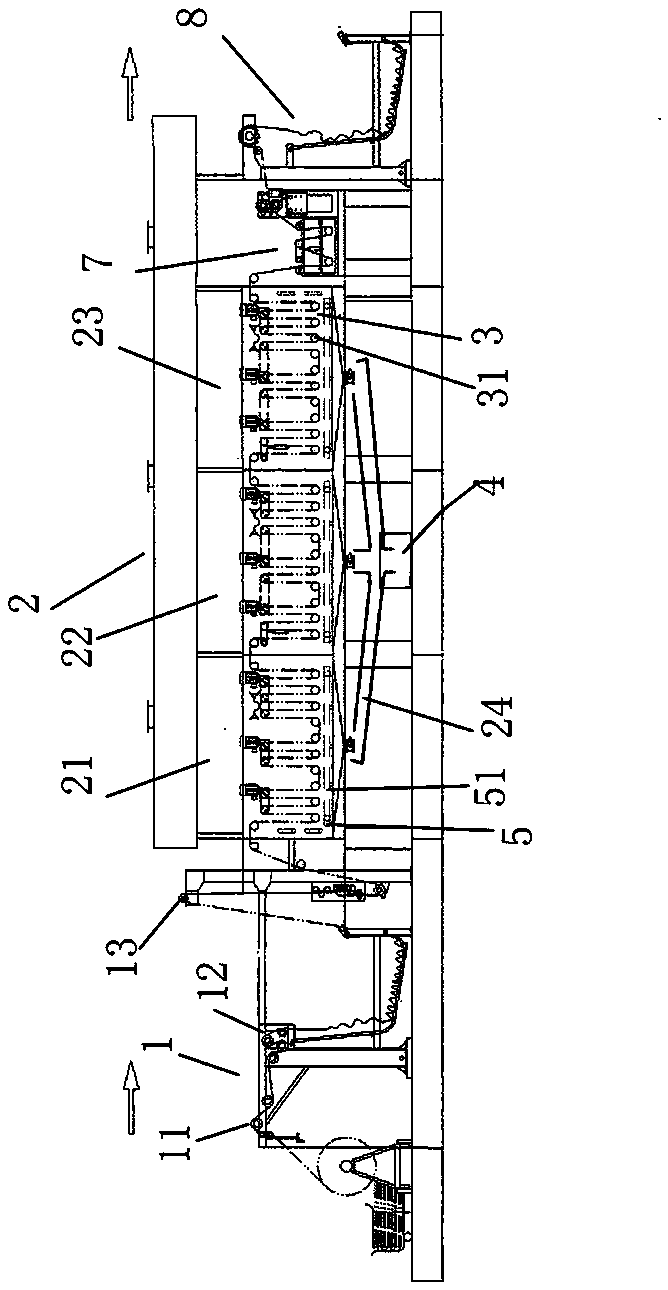

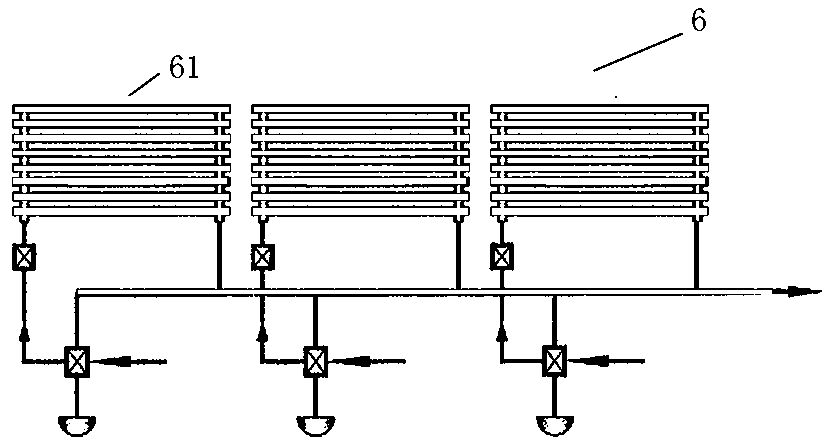

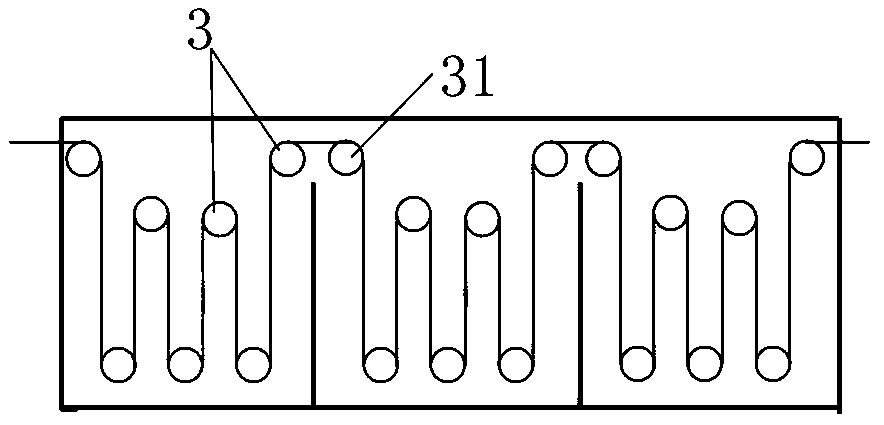

[0035] Please refer to Figure 1 to Figure 4 In the figure, the device for recovering real wax anti-printing fabric wax based on hot water hot wax processing includes a cloth feeding unit 1, a waxing box 2, a waxing guide cloth guide mechanism 3, a wax-water separator 4, and a steam Generator 5, a temperature control mechanism 6, a hot alkali flat washing tank 7, and a cloth output unit 8.

[0036] The cloth feeding unit 1 includes a cloth feeding roller 11, a cloth stacking roller 12, and a spreader roller 13, which are arranged sequentially according to the feeding direction of the cloth; The printed fabric is imported into the waxing box 2. Enter cloth roller 11, pile cloth roller 12, expander roller 13 and all are existing structures.

[0037] Wax has the physical property of softening at 82°C and naturally falls off from the cloth surface in hot water at 96°C. In order to make full use of the properties of wax, a waxing box 2 is specially designed for wax recovery. Wax...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com