Structure-pillar free combined openwork brick wall without plastering and construction method thereof

A technology of constructing columns and clear water, which is applied to building structures, walls, building components, etc., can solve the problems of poor stability of hollow clear-water brick walls, inability to set structural columns in the walls, and affecting the overall appearance of the walls. Fast speed, beautiful appearance, neat masonry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be described in further non-limiting detail below in conjunction with the embodiments and accompanying drawings.

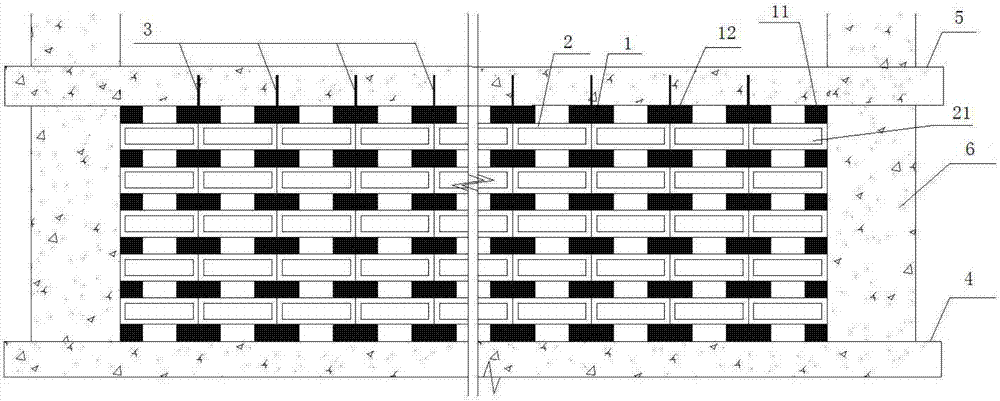

[0030] Such as Figures 1 to 4 As shown, a hollowed-out clear water brick wall without structural columns includes a stone layer 1 spliced between the upper and lower beam structures, a concrete hollow block layer 2 and a steel bar 3, and the stone layer 1 and the concrete hollow block layer 2 The upper and lower joints are spliced in the order of "stone block layer-concrete hollow block layer-stone block layer-concrete hollow block layer-...-stone block layer" from bottom to top. The bottom layer of the wall and the The top layer is stone layer 1.

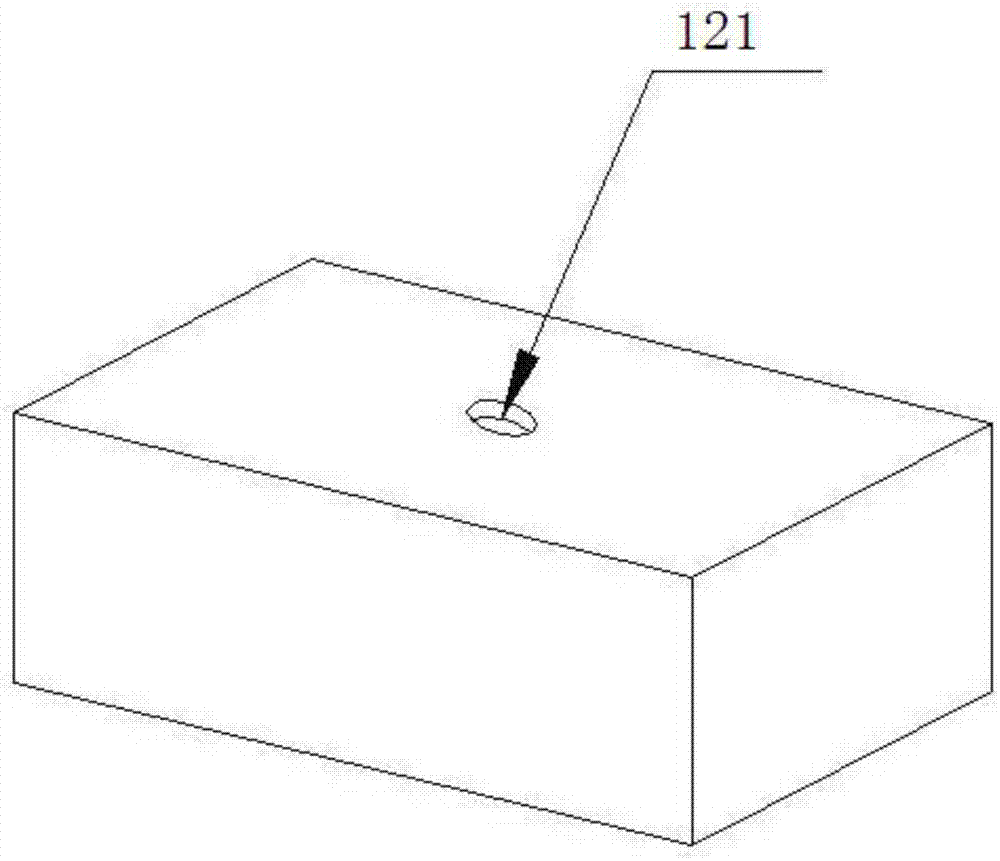

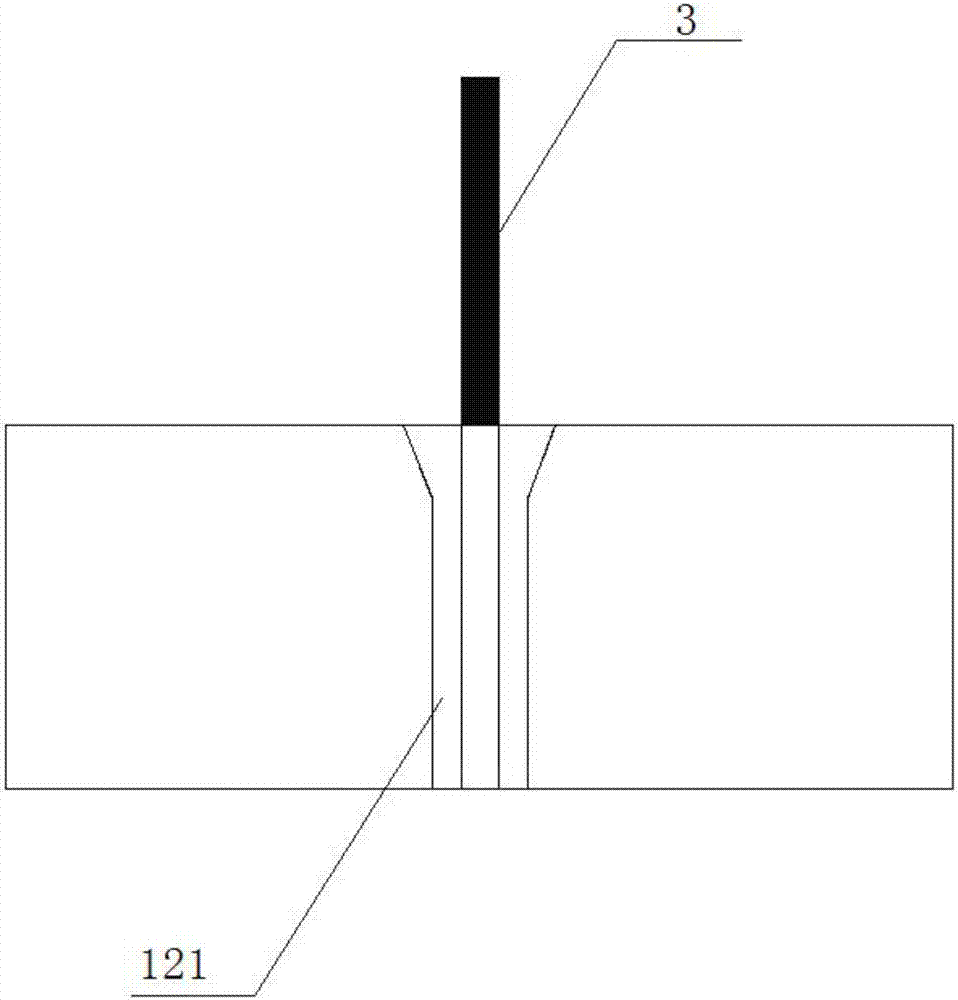

[0031] Stone layer 1 is made up of first stone 11 and second stone 12, and first stone 11 is arranged on both sides of body of wall and is fixed with room column 6, and second stone 12 is arranged on two sides of wall both sides. There are gaps between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com