Tunnel construction comprehensive trolley

A technology of tunnel construction and trolley, applied in tunnels, tunnel linings, bridge forms, etc., can solve the problems of construction technology, construction quality and progress cannot be guaranteed, and achieve the effect of reducing the labor intensity of workers and reducing the quality of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

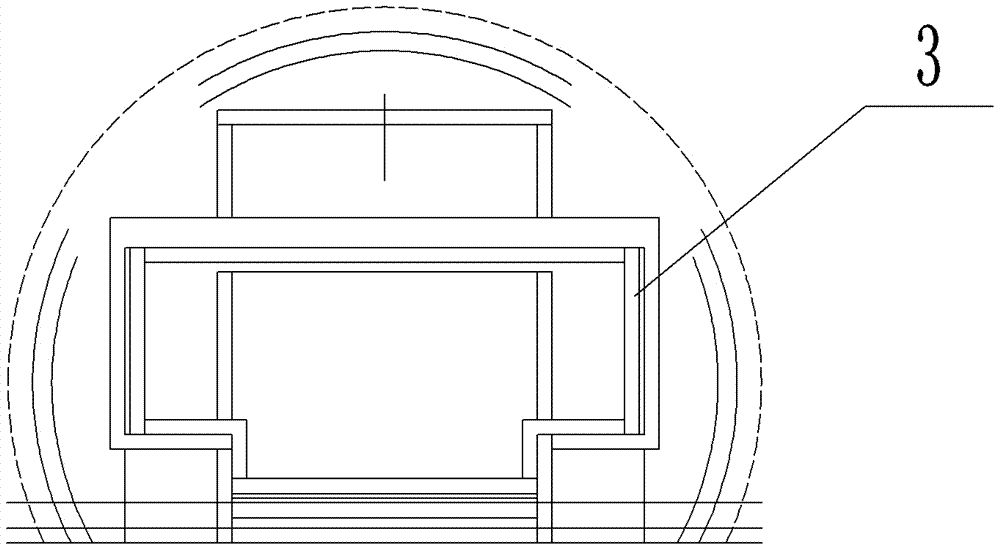

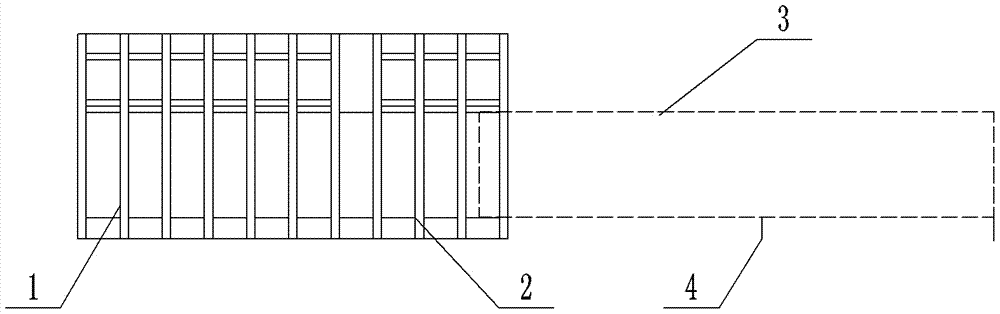

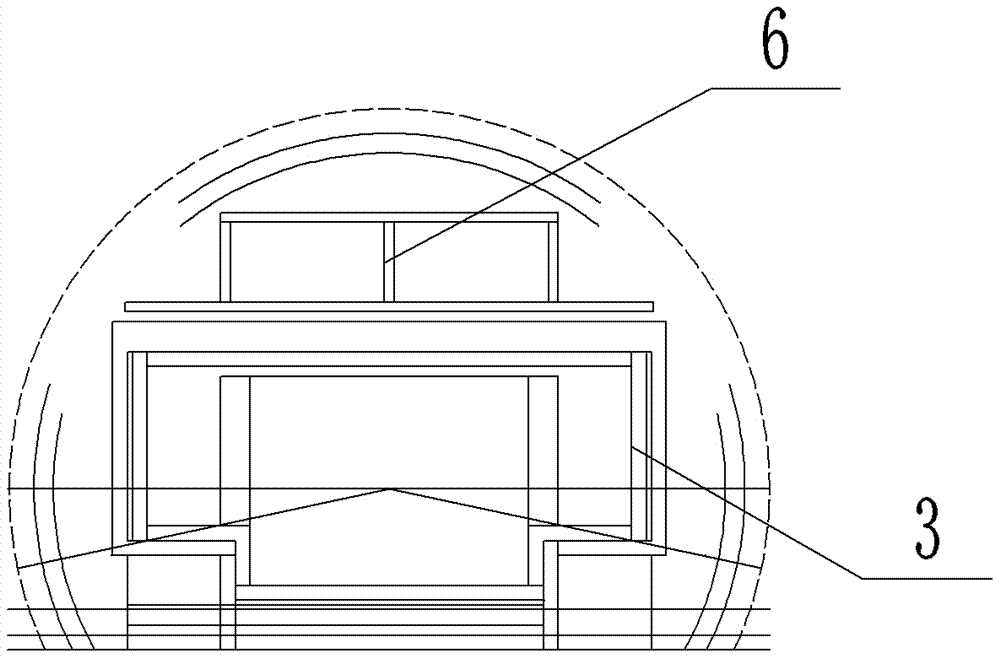

[0038] Embodiment two is basically as attached image 3 And attached Figure 4 As shown, the only difference from Embodiment 1 is that it also includes at least one translation trolley 6 that can walk on the self-propelled trestle 3, and the self-propelled trestle 3 is provided with a second walking rail for the translation trolley 6 to walk, and the translation trolley 6 The shape is an arc designed to imitate the arc of the tunnel vault. The bottom of the translation trolley 6 is equipped with track wheels. Positioning device, jackhammer positioning device and manipulator.

[0039] After the self-propelled trestle 3 walks out, the translation trolley 6 walks on the second walking rail for construction, and the workers enter the liftable working platform of the translation trolley 6, and place materials such as anchor rods and arches on the translation trolley 6. According to the construction requirements, control the lifting of the liftable working platform and the manipul...

Embodiment 3

[0040] Embodiment three, basically as attached Figure 5 And attached Figure 6 As shown, the only difference with Embodiment 2 is that it also includes the excavation and arch installation trolley track 7 walking inside the self-propelled trestle 3, and the self-propelled trestle 3 is provided with a trolley track for excavation and arch installation. 7. The second track for sliding, the trolley track for excavation and arch installation Car track 7 front end bottoms are provided with the second crawler dolly support 5, and excavation and arch frame installation trolley track 7 and the second crawler dolly support 5 are all controlled by control mechanism.

[0041] After the excavation and arch installation trolley track 7 advances to the tunnel face, it is supported by the second crawler trolley support 5 after it travels, and the control mechanism controls the translational trolley 6 to move longitudinally on the third travel track to the tunnel face , Construction is car...

Embodiment 4

[0042] Embodiment four, basically as attached Figure 7 And attached Figure 8 As shown, the only difference from Embodiment 1 is that it also includes an integral inverted arch template 8 that can walk outside the self-propelled trestle 3 and is controlled by a control mechanism. Ditch mould, the self-propelled trestle 3 is provided with the 4th walking rail for integral type inverted arch formwork 8 walking, and self-propelled trestle 3 and integral type inverted arch template are detachably connected.

[0043] Since the existing inverted arch formwork generally only has side molds, only the two ends of the inverted arch after forming are arc-shaped, and the concrete self-leveling plane in the middle is a combination of inverted arches at different positions, so that the inverted arch, arch wall and side wall cannot form a single It is a complete arc closed loop, and it takes time and effort to install the inverted arch formwork and side forms. The setting of this device ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com