Variable-frequency loading intelligent brake testing system and method

A testing system and brake technology, which is applied in the testing of machine/structural components, testing of mechanical components, instruments, etc., can solve problems such as testing the braking performance of intelligent brakes, achieve less parts, smooth braking process without impact, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

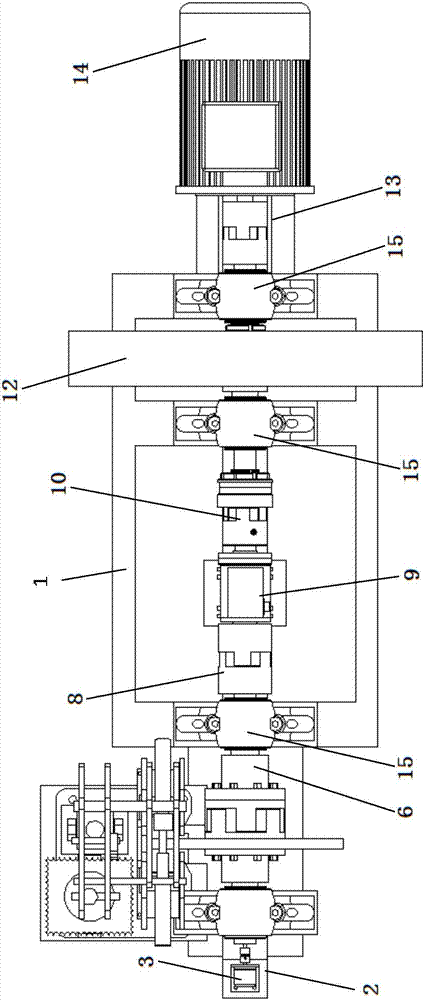

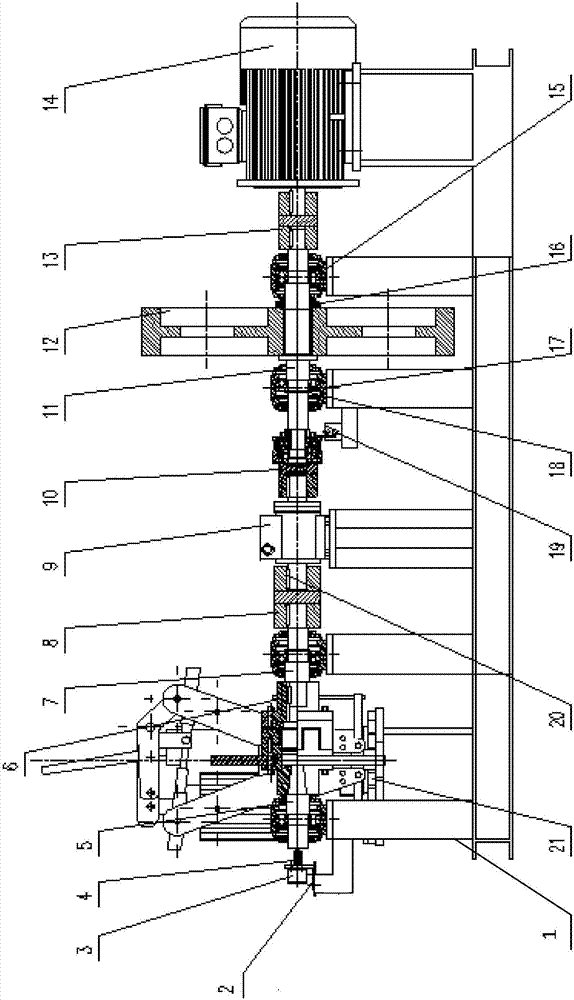

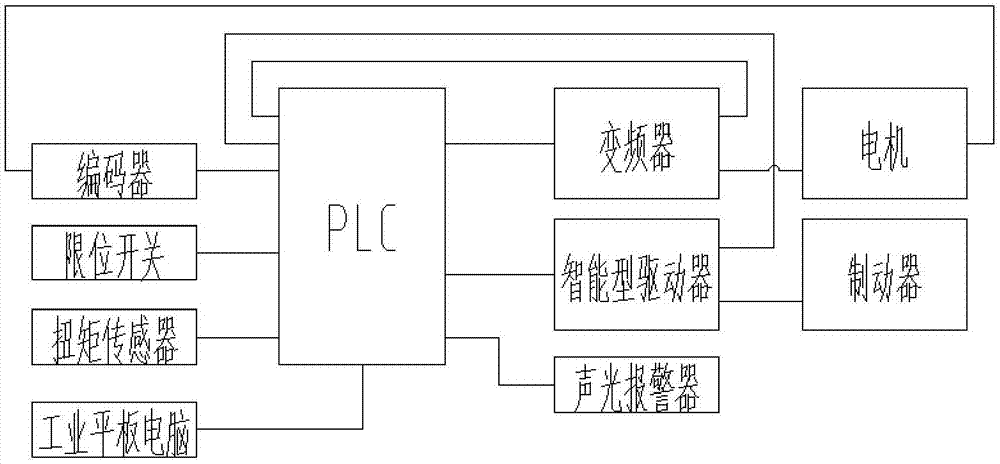

[0032] combine figure 1 and figure 2 As shown, the present invention firstly provides a variable frequency loading intelligent brake testing system, including: a pedestal 1; an encoder support 2; an absolute value angle encoder 3; a first elastic coupling 4; Brake disc 6; brake disc right shaft 7; second elastic coupling 8; dynamic torque sensor 9; torque limiting coupling 10; inertia wheel shaft 11; flywheel 12; third elastic coupling 13; AC motor 14; bearing housing 15; round nut 16; bearing 17;

[0033] Among them, specifically, the pedestal 1 is respectively connected with the encoder support 2, the dynamic torque sensor 9, the AC motor 14, the bearing seat 15, the limit switch 19 and the intelligent brake 21 with high-strength bolts, and the encoder support 2 and the absolute value angle encoder 3 are connected with ordinary bolts. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com