Thin-film circuit electromagnetic shielding packaging method

A technology of electromagnetic shielding and thin-film circuits, applied in circuit devices, printed circuits, printed circuits, etc., can solve problems such as poor productivity, high circuit cost, and large volume, and achieve the effect of improving production efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

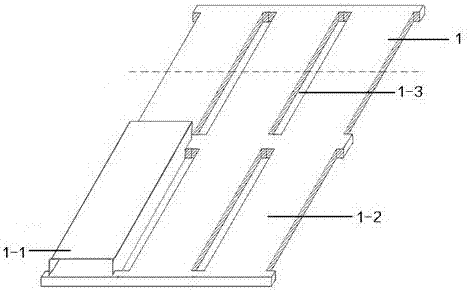

[0027] A thin film circuit electromagnetic shielding packaging method, such as figure 1 , figure 2 and image 3 As shown, the specific method is:

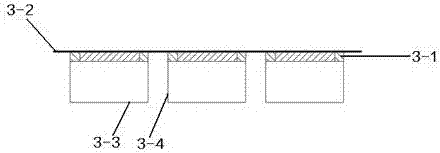

[0028] 1. Paste the front side of the substrate 1 that has completed the arrayed circuit arrangement on the high-temperature tape 3-2;

[0029] 2. Cover the back 3-3 and side 3-4 of the circuit chip with solder;

[0030] 3. Remove the high temperature tape;

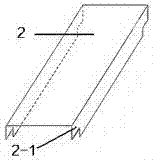

[0031] 4. Select the metal cover 2 corresponding to the size of each circuit slice, fold down the metal cover and insert the edge sealing 2-1 into the substrate through cavity 1-3, so that the outer edge of the sealing edge is aligned with the bottom of the circuit chip, and the inner wall is aligned with the circuit close to;

[0032] 5. Turn over the clamped array structure so that the solder on the bottom surface is upward and fixed, and realize the batch welding and packaging of the metal cover and the thin film circuit chip through reflow soldering;

[0033] In the...

specific Embodiment 2

[0039] On the basis of the specific embodiment 1, the method further includes: obtaining the required independent devices by laser slicing after the welding is completed. After the overall welding is completed, the required self-shielding film circuit device can be obtained by dividing into pieces according to the circuit size.

specific Embodiment 3

[0040] On the basis of the specific embodiment 1 or 2, the specific method of coating the solder resist film on the front of each slice is: after the front of the substrate made of arrayed circuit arrangement is coated with a layer of solder resist film, the photolithography pattern Obtain the solder resist ring 3-1 of each circuit slice. After completion, use high temperature tape 3-2 to stick to the front of the substrate as a barrier layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com