Multi-DOF (degree of freedom) automated stereoscopic seedbed system with adjustable light transmittance

A light transmittance, adjustable technology, applied in the field of greenhouse seedbed logistics system, can solve the problems of inflexible and labor-saving adjustment, inconvenient light transmittance adjustment, low natural light rate, etc., to achieve low operating and management costs, increase Good light utilization and system flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

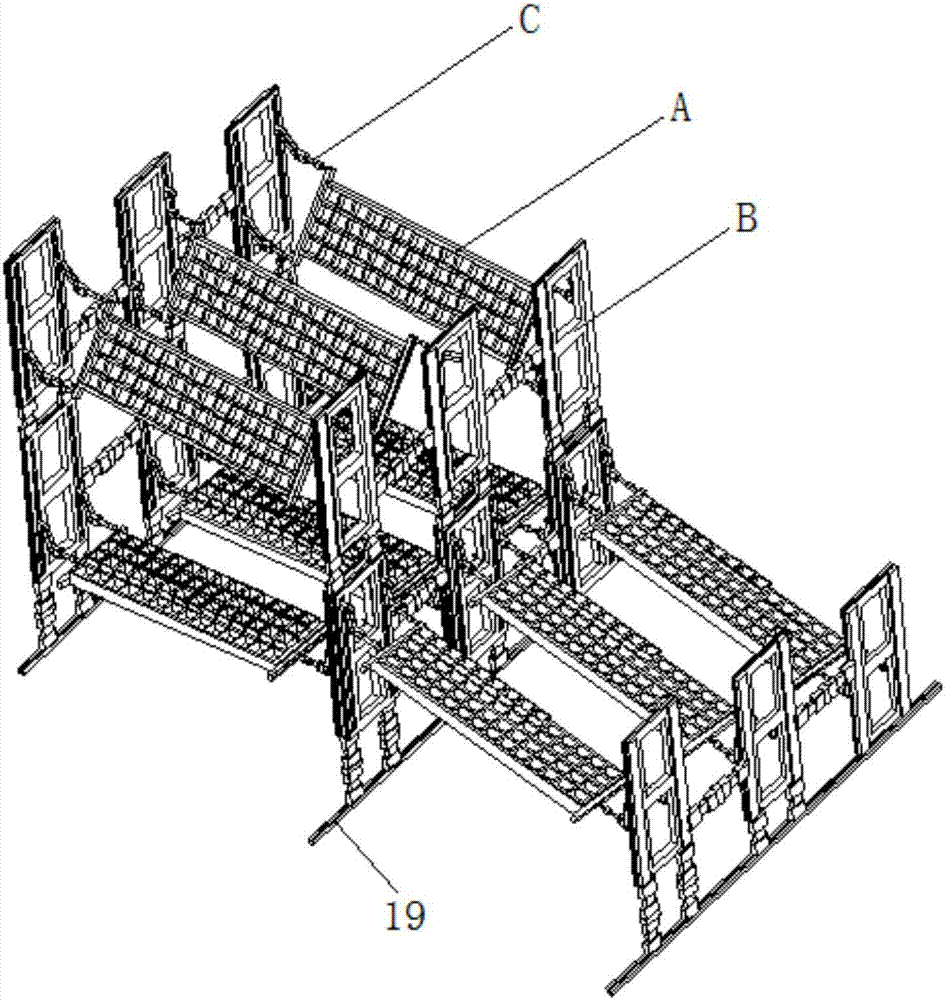

[0049] A multi-degree-of-freedom automatic three-dimensional seedbed system with adjustable light transmittance, such as figure 1 shown, including:

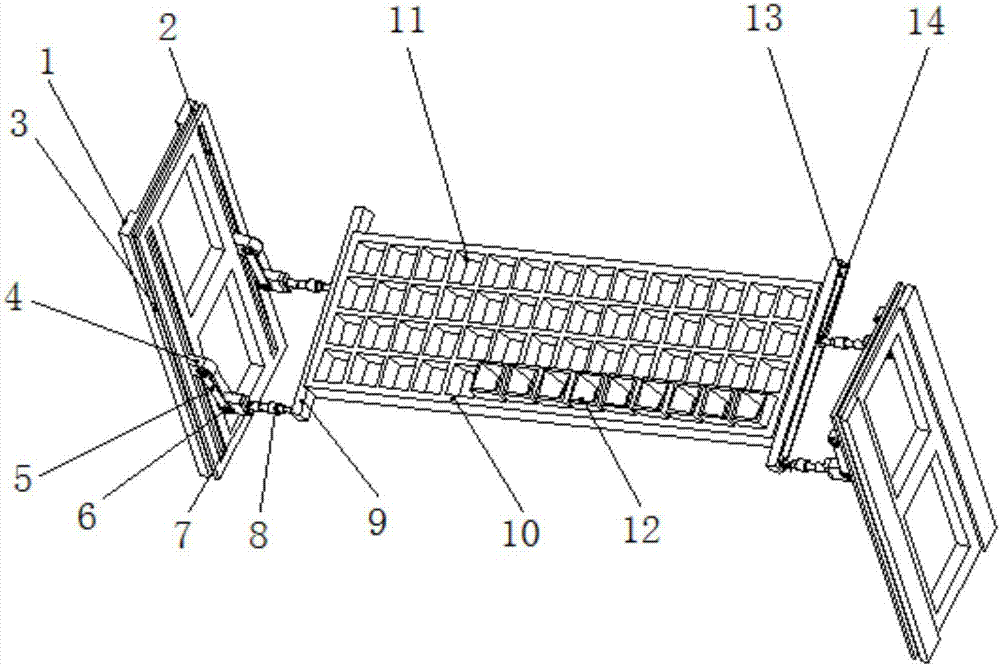

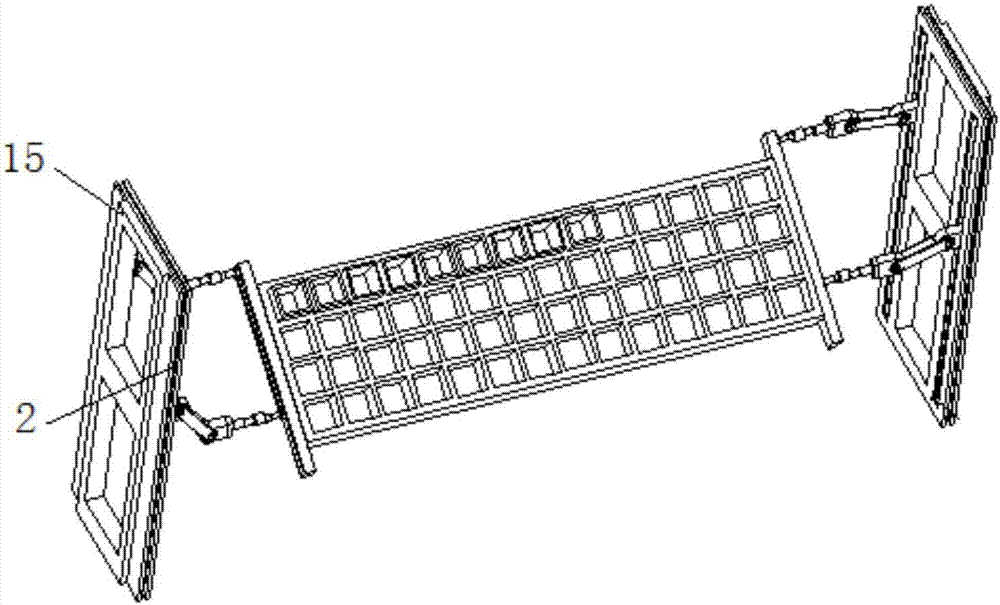

[0050] Single seedbed A: such as Figure 7 As shown, it is used to carry plant seedlings, including a main body seedbed frame 10, and the two sides of the main body seedbed frame 10 are provided with side grooves 13 along the side edges of the seedbed 9; the seedbed support frame B: a linear guide rail vertically installed on the ground 19, used to install the single seedbed A; rotating connection mechanism C: located between the single seedbed A and the seedbed support frame B, used for the connection of the single seedbed A and the seedbed support frame B, such as Figure 6 As shown, it includes sequentially connected mobile slider 4, connecting bar 5, connecting shaft 6, telescopic cylinder 7, connecting shaft 8 and rotating connecting shaft 14; drive positioning mechanism: to position and control the movement of the seedbed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com