Welding structure of 460MPa-grade anti-seismic fireproof and weather-resistant building structure

A technology of fire resistance and weather resistance, building structure, applied in welding medium, welding equipment, welding equipment and other directions, can solve the problems of difficult fire resistance, weather resistance, earthquake resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1. The mass percentage of chemical composition of submerged arc welding wire should meet: C 0.08%, Mn 1.3%, Si 0.80%, S0.005%, P 0.008%, Cr 0.01%, Ni 0.9%, Mo 0.5%, Cu 0.25%, Ti 0.0125%, Nb 0.002%, As 0.001%, Sn 0.001%, Sb 0.001%, Al 0.024%, O 0.0015%, N≤0.0045%, B≤0.0003%, and the rest is iron.

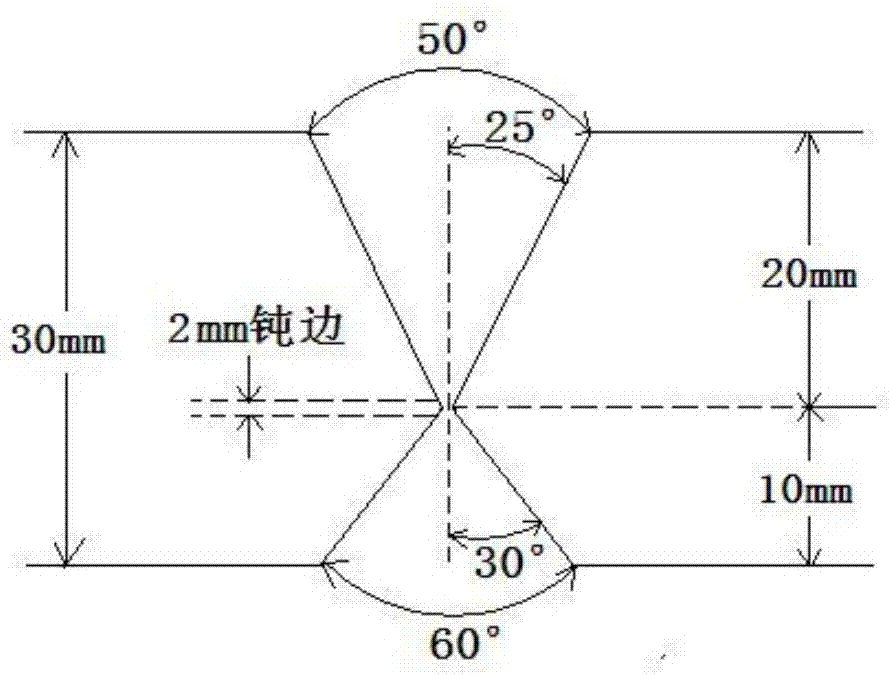

[0016] 2. Choose 460MPa fire-resistant and weather-resistant steel with a thickness of 30mm, and make an asymmetrical X-shaped groove on the test plate. The groove is as follows: figure 1 As shown, the size of the steel plate is 600mm×200mm×30mm, leaving 2mm blunt edge and leaving no gap between the two plates.

[0017] 3. The chemical composition of 460MPa fire-resistant and weather-resistant steel is selected to meet: C0.05%, Mn1.0%, Si≤0.26%, S0.005%, P 0.007%, Cr 0.50%, Ni 0.12%, Mo 0.25%, Cu 0.32 %, Ti 0.013%, Nb 0.05%, As 0.0002%, Sn 0.0002%, Sb 0.0002%, Al 0.03%, O 0.002%, N 0.0043%, B0.0005%, and the rest is iron.

[0018] 4. The mechanical properties of 460MPa fire-...

Embodiment 2

[0023] 1. The mass percentage of chemical composition of submerged arc welding wire meets: C0.08%, Mn 1.3%, Si 0.80%, 0.005%, P 0.008%, Cr 0.01%, Ni 0.9%, Mo 0.5%, Cu 0.25%, Ti 0.0125 %, Nb 0.002%, As 0.001%, Sn 0.001%, Sb 0.001%, Al 0.024%, O 0.0015%, N≤0.0045%, B≤0.0003%, and the rest is iron.

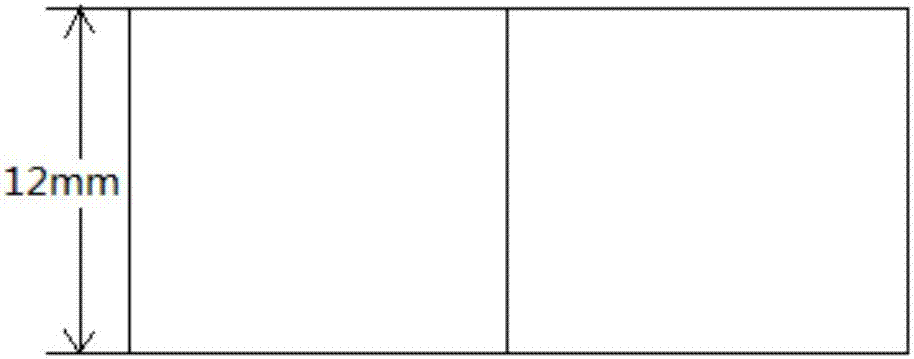

[0024] 2. Choose 460MPa fire-resistant and weather-resistant steel with a thickness of 12mm, and open the I-shaped groove on the test plate. The groove is as figure 2 As shown, the size of the steel plate is 600mm×200mm×12mm, and there is no gap between the two plates.

[0025] 3. The chemical composition of 460MPa fire-resistant and weather-resistant steel is selected to meet: C 0.05%, Mn1.1%, Si≤0.28%, S0.005%, P 0.008%, Cr 0.30%, Ni 0.50%, Mo 0.30%, Cu 0.25% , Ti 0.015%, Nb 0.03%, As 0.0002%, Sn 0.0002%, Sb 0.0002%, Al 0.027%, O 0.0018%, N 0.0054%, B0.0004%, and the rest is iron.

[0026] 4. The mechanical properties of 460MPa fire-resistant and weather-resistant steel are sele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature yield strength | aaaaa | aaaaa |

| Room temperature tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com