Orangered glass and production method and application thereof

An orange-red, glass technology, applied in the field of glass preparation, can solve problems such as easy film release, and achieve the effect of reasonable formula, good elastic modulus and full color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

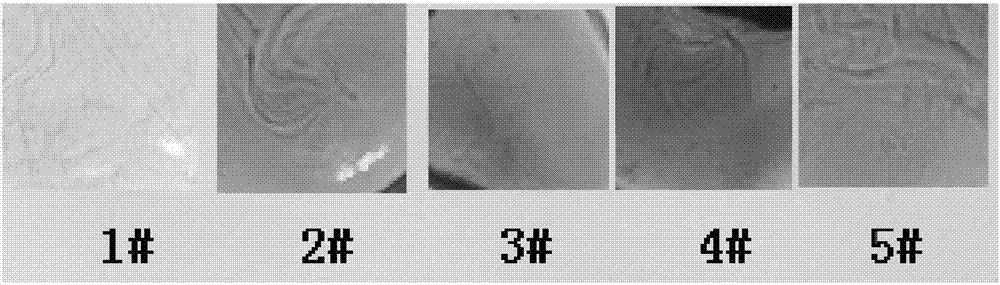

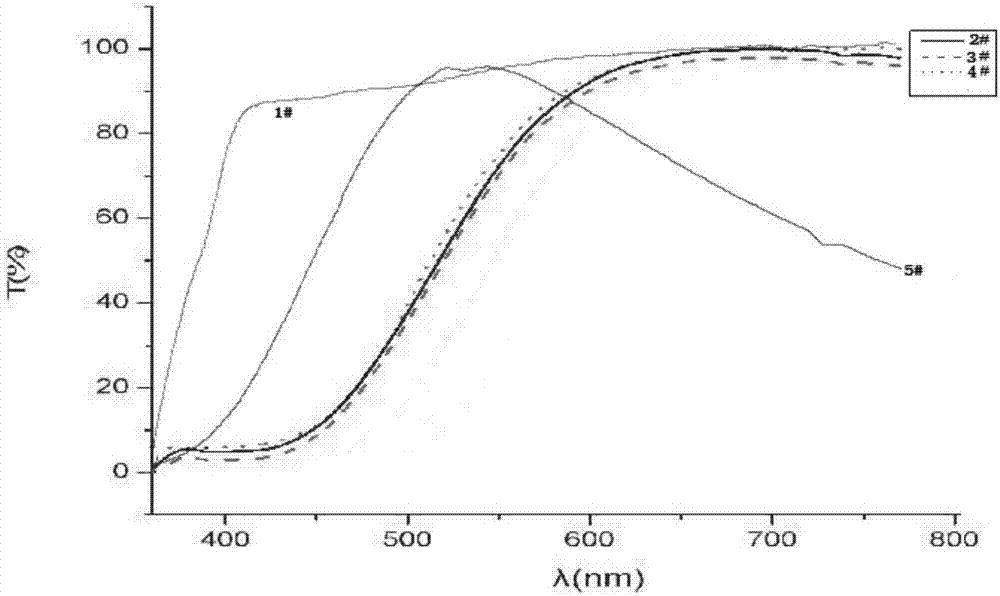

Embodiment 1-5

[0027] Embodiments 1-5 have different glass composition ratios, and the preparation method is the same, and the glass compositions of 5 embodiments are prepared according to Table 1:

[0028] Table 1. Basic composition of orange-red glass

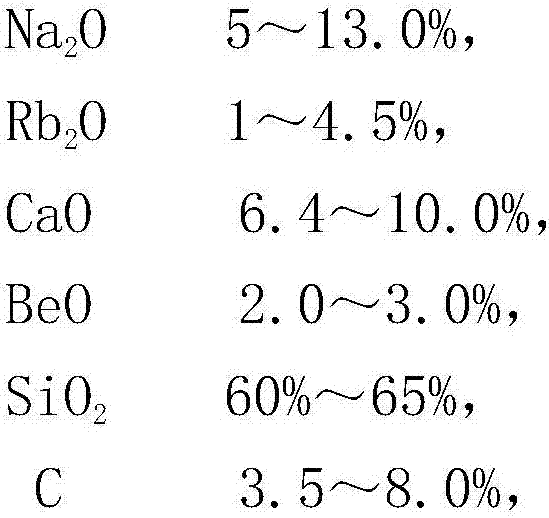

[0029] components

Na 2 o

Rb 2 o

CaO

BeO

SiO 2

C

Se

Na 2 SO 4

Example 1

8.20%

4.50%

9.8%

3.00%

64%

0

9.50%

1%

Example 2

12.00%

1.40%

8.5%

2.00%

65%

3.50%

5.50%

1%

Example 3

11.50%

2.50%

7.5%

2.60%

62%

6.10%

6.80%

1%

Example 4

7.60%

1.50%

6.5%

2.40%

61%

8.00%

12%

1%

Example 5

11.00%

4.40%

9.9%

2.20%

65%

6.50%

0

1%

[0030] According to Table 1. The design composition is converted into the quality of sodium carbonate, rubidium chloride, limestone, beryllium hydroxide, silica sand, carbon powder, selenium powder, sodium sulfate respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com