Preparation method of modified triethanolamine

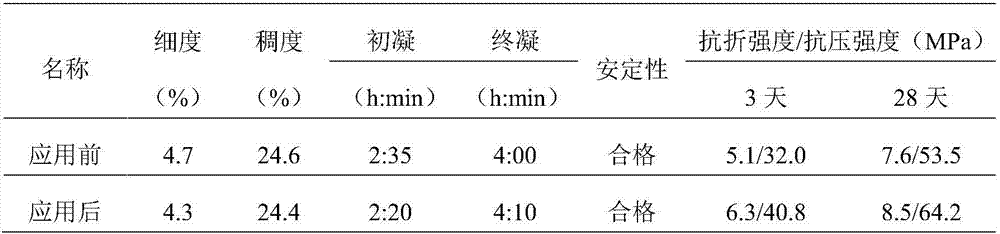

A technology of triethanolamine and modification, which is applied in the preparation of organic compounds, chemical instruments and methods, preparation of aminohydroxy compounds, etc., can solve problems such as poor stability and insufficient strength, and achieves low production cost, simple operation and high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Add 28.00g of maleic anhydride, 74.59g of triethanolamine, and 4.16g of p-toluenesulfonic acid into a 250ml four-neck bottle equipped with a mechanical stirring device, a circulating condensing device, a thermometer, and stir evenly, then raise the temperature, open the circulating condensing pipe, and control the temperature Add 21.03g of maleic anhydride into the reactor three times at a temperature between 100 and 110°C. After the maleic anhydride is added, keep it warm for 2 hours to obtain the modified triethanolamine product. Samples are taken for gas chromatography analysis, and the yield is 88.79%.

Embodiment 2

[0015] Add 28.00g of maleic anhydride, 74.59g of triethanolamine, and 4.16g of concentrated sulfuric acid into a 250ml four-necked bottle equipped with a mechanical stirring device, a circulating condensing device, a thermometer, and stir evenly, then raise the temperature, open the circulating condensing pipe, and control the temperature at 100 Between ~110°C, add 21.03g of acetic acid into the reactor three times. After the maleic anhydride is added, keep it warm for 2 hours to obtain the modified triethanolamine product with a yield of 91.5%.

Embodiment 3

[0017] Add 28.00g of maleic anhydride, 59.67g of triethanolamine, and 4.16g of p-toluenesulfonic acid into a 250ml four-necked bottle equipped with a mechanical stirring device, a circulating condensing device, a thermometer, and stir evenly, then raise the temperature, open the circulating condensing pipe, and control the temperature Add 21.03g of maleic anhydride into the reactor three times at 100-110°C. After the maleic anhydride is added, keep it warm for 2 hours to obtain the modified triethanolamine product. Samples are taken for gas chromatography analysis, and the yield is 94.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com