Starch octenyl succinate as well as preparation method and application thereof

A technology of octenyl succinic acid and starch ester, applied in chemical instruments and methods, transportation and packaging, dissolution, etc., can solve the problems of insufficient emulsification performance, low encapsulation rate, high surface oil, etc., and achieve the goal of encapsulation Improved embedding stability, improved emulsification performance, and good emulsification and film-forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Waxy cornstarch and octenyl succinic anhydride synthesized under wet conditions octenyl succinic acid starch ester configuration 500g mass fraction is 1% (w / w) starch milk, fully gelatinized in a boiling water bath, Afterwards, high-pressure homogenization under 20 MPa pressure once, then add 500 g of octenyl succinic acid starch ester milk with a mass fraction of 25% (w / w) to the starch paste after homogenization, and fully gelatinize in a boiling water bath , then homogenize under high pressure once under 20MPa pressure, cool down to 55°C, and adjust the pH value of the starch paste to 5.5;

[0026] Add 0.15% glucoamylase relative to the starch mass for enzymolysis, maintain the system at 55°C for 4 hours, raise the temperature to 80°C after the reaction, stir for 30 minutes to kill the enzyme, freeze-dry, and pulverize to obtain the finished product.

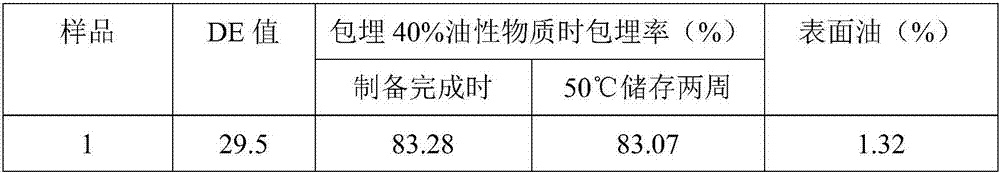

[0027] The DE value of the finished product was measured, and microcapsules were prepared at the same time to invest...

Embodiment 2

[0031] Waxy cornstarch and octenyl succinic anhydride synthesized under wet conditions octenyl succinic acid starch ester configuration 500g mass fraction is 8% (w / w) starch milk, fully gelatinized in a boiling water bath, Afterwards, under the pressure of 80MPa, homogenize under high pressure for 2 times, then add 500g of octenyl succinic acid starch ester milk with a mass fraction of 30% (w / w) into the starch paste after homogenization, and fully gelatinize in a boiling water bath , followed by high-pressure homogenization twice under 80MPa pressure, cooling to 55°C, and adjusting the pH value of the starch paste to 5.5;

[0032] Add 0.15% glucoamylase relative to the starch mass for enzymolysis, maintain the system at 55°C for 4 hours, raise the temperature to 80°C after the reaction, stir for 30 minutes to kill the enzyme, freeze-dry, and pulverize to obtain the finished product.

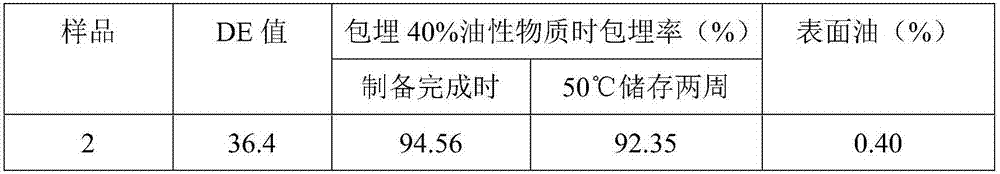

[0033] The DE value of the finished product was measured, and microcapsules were prepared at...

Embodiment 3

[0037] Waxy cornstarch and octenyl succinic anhydride synthesized under wet condition octenyl succinic acid starch ester configuration into 500g mass fraction is 10% (w / w) starch milk, fully gelatinized in boiling water bath, Afterwards, 4 times of high-pressure homogenization under 140 MPa pressure, then 500 g of octenyl succinic acid starch ester milk with a mass fraction of 35% (w / w) was added to the starch paste after homogenization, and fully gelatinized in a boiling water bath , then homogenize under high pressure for 4 times under 140MPa pressure, cool down to 55°C, and adjust the pH value of the starch paste to 5.5;

[0038] Add 0.15% glucoamylase relative to the starch mass for enzymolysis, maintain the system at 55°C for 4 hours, raise the temperature to 80°C after the reaction, stir for 30 minutes to kill the enzyme, freeze-dry, and pulverize to obtain the finished product.

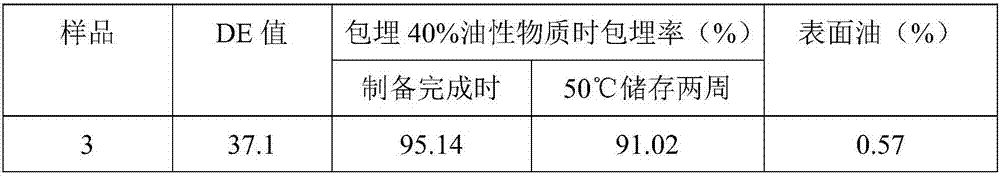

[0039] The DE value of the finished product was measured, and microcapsules were prepared a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com