Method for physically separating aluminum metal from metal mixture

A metal mixture and physical separation technology, applied in the direction of improving process efficiency, can solve the problems of increased recycling cost, low economic value, environmental pollution, etc., and achieve the effect of high recycling rate and high degree of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

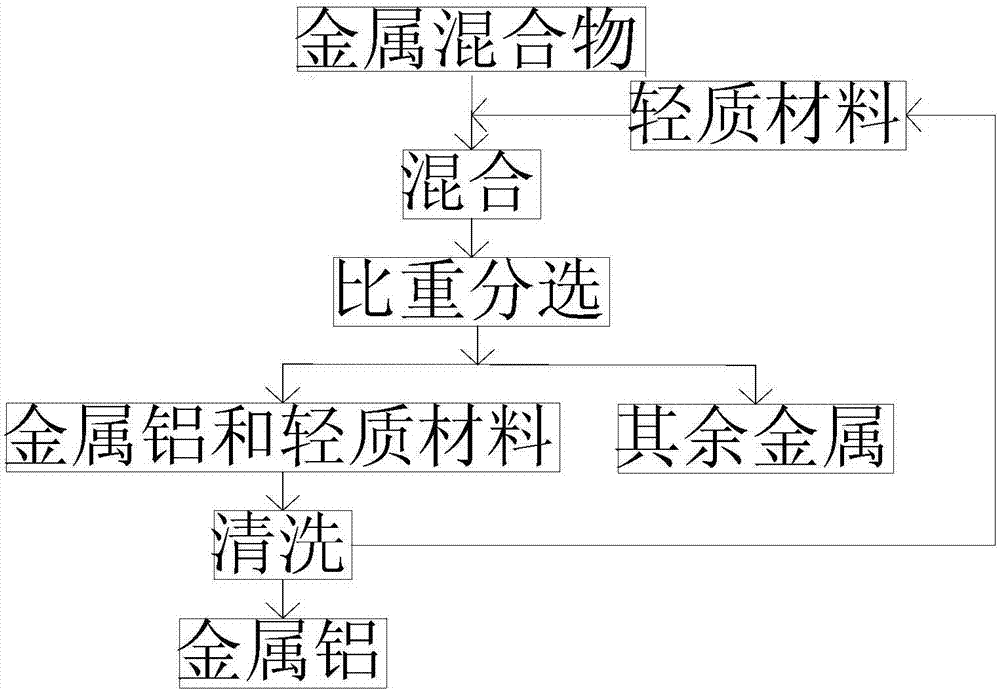

[0023] refer to figure 1 The process flow of a method for physically separating aluminum metal from a metal mixture provided in this embodiment is as follows:

[0024] Firstly, the metal mixture containing aluminum metal is mixed with light materials, and the surface specific gravity of aluminum metal is reduced by mixing with light materials, and then the specific gravity is sorted; here, the light material is oil, and the specific gravity sorting is selected Lithium bromide saturated solution, because the specific gravity of lithium bromide solution is greater than the average specific gravity of aluminum metal and light material after mixing, so aluminum metal and light material float in lithium bromide saturated solution, while the rest of the metal sinks, so that aluminum metal and light material The light material is separated from the rest of the metal; then the aluminum metal and the light material are cleaned to obtain the aluminum metal and the rest of the metal; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com