Etching solution composition for molybdenum-containing metal film and manufacturing method for array substrate for display using the same

A technology of composition and etching solution, which is applied in the direction of surface etching composition, chemical instrument and method, semiconductor/solid-state device manufacturing, etc., can solve the problems of increased process cost, short service life, large difference in etching performance, etc., and achieve change The effect of small amount and excellent service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

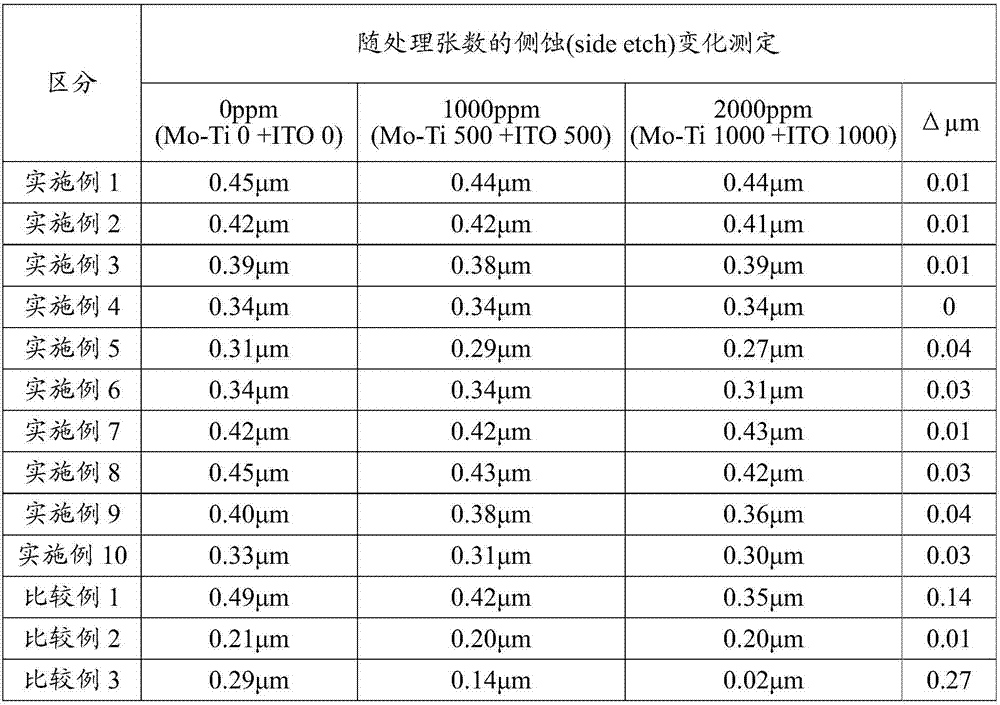

[0073] Experimental example 1. Measurement of side etch variation with the number of sheets processed

[0074] In the experimental equipment (model name: ETCHER (TFT), SEMES company) of jet etching mode, respectively pack the etching liquid composition of above-mentioned embodiment 1~10 and comparative example 1~3, set the temperature of etching liquid composition It is about 35°C and heated. The total etching time can vary depending on the etching temperature, and the molybdenum-based metal film and the metal oxide film are usually performed in about 80 to 100 seconds in the LCD etching process.

[0075] When measuring the amount of side erosion change with the number of sheets processed, the Mo-Ti and ITO powder contained in the film quality can be used to reflect the change of the metal concentration (ppm) in the composition of the etching solution with the etching of the substrate. The method of putting in the composition is carried out. In the case of 1,000ppm, 500ppm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com