Spiral conveying device with mud filtering function

A technology of screw conveying device and function, applied in the field of screw conveying device, can solve the problems such as difficulty in selecting screen mesh, easy blocking of screen, long cycle and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

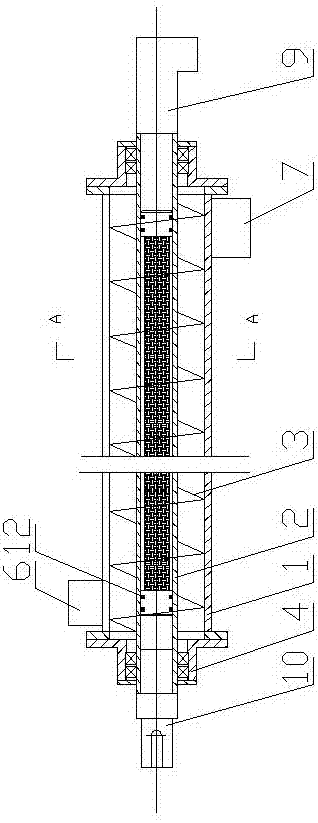

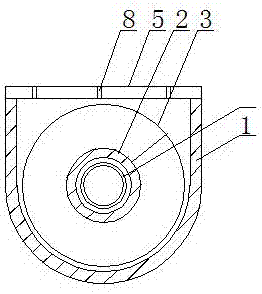

[0026] The screw conveying device with mud filtering function includes a trough 1, a drive shaft 2 and a blade 3. The trough 1 is equipped with a drive shaft 2 through a symmetrically arranged bearing seat 4, and the drive shaft 2 is screwed with blades 3 to Promote materials forward during work. The cross section of the trough 1 of the screw conveying device is a U-shaped body, a cover plate 5 is arranged on the trough 1 and the cover plate 5 is evenly distributed with air holes 8. A feed port 6 is provided at the top of one end of the trough 1, and a discharge port 7 is provided at the bottom of the other end of the trough 1. One end of the drive shaft 2 extends to the outer end of the front part of the trough 1, and the drive shaft 2 extending to the outer end of the front part of the trough 1 is sealed with a rotating head 9 to connect the vacuum device during work; so that the trough 1 Negative pressure is formed inside. The other end of the drive shaft 2 extends to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com