Water circulating sand tank test device for confined water seepage model

A test device, pressurized water technology, applied in the direction of measuring device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems that the research needs to be further strengthened, and achieve simple structure, strong operability, and structure Easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

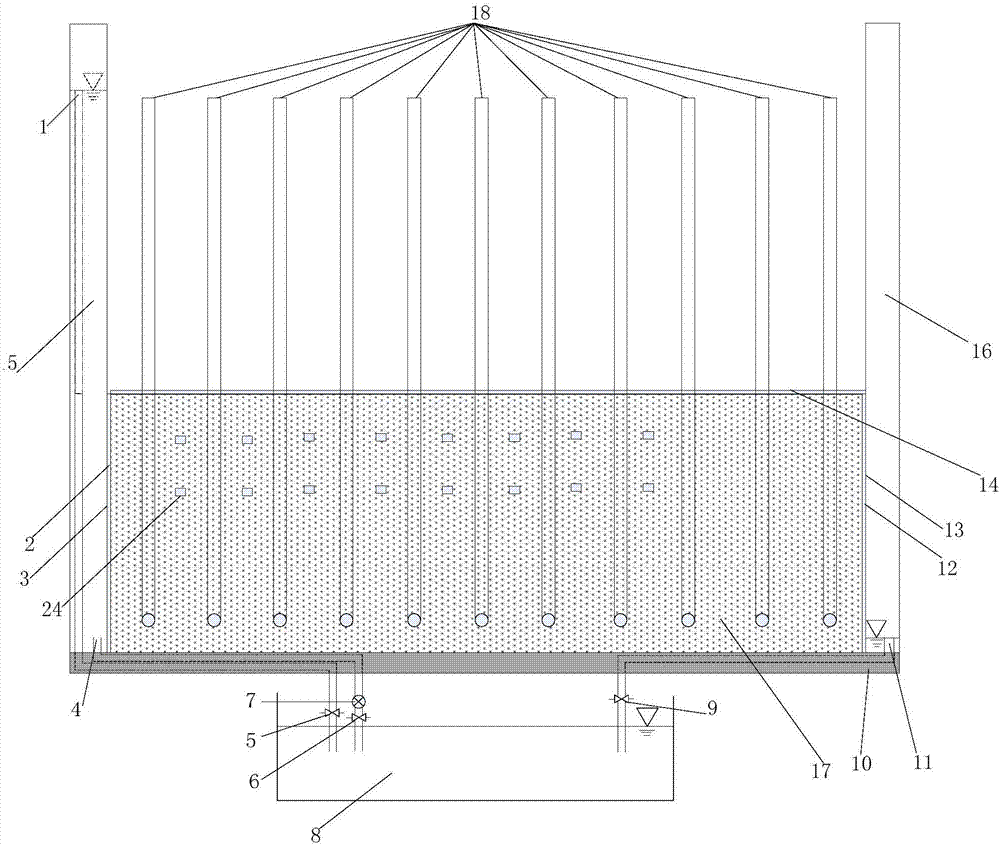

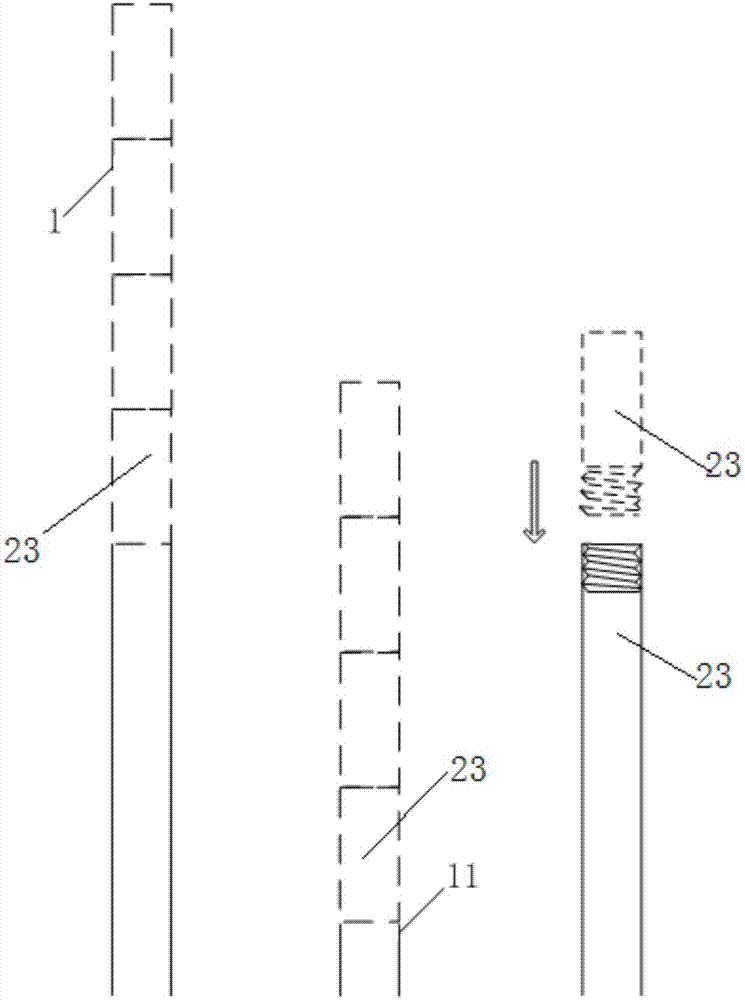

[0061] Example 1 Test of stable seepage characteristics of confined water

[0062] figure 1 It is a front view of the overall structure of the experimental device of the present invention. The water circulation sand tank test device for the confined water seepage model of the present invention can simulate the stable seepage process of the confined water. The principle of the stable seepage test is: first lay the test sand in the sand tank, then cover the top cover plate 14, and seal it with waterproof glue. Turn on the water pump 7, open the valves 5 and 6, the water flow is pumped out from the water tank 8, and enters the infiltration tank 15 through the inflow port 4. When the water level rises to the height of the overflow port 1, the water level does not rise any more, and the constant water head is maintained in the infiltration tank condition. The water in the seepage tank 15 enters the sand tank 17 through the seepage barrier 2 and the anti-seepage screen 3, and then...

Embodiment 2

[0068] Example 2 Test of Unsteady Seepage Characteristics of Confined Water

[0069] The water circulation sand tank test device used in the pressurized water seepage model of the invention can simulate the unsteady seepage process of the pressurized water.

[0070] The principle of the unsteady seepage test is: first lay test sand in the sand tank, and bury the pore water pressure sensor, then cover the top cover plate 14, and seal it with waterproof glue. Referring to the steady seepage test procedure, first make the device in a steady seepage state. Then water pump 7 and valve 6 are closed simultaneously, and water flows into sand tank 17 through infiltration dividing plate 2 and anti-seepage screen 3, and then flows into the seepage tank 16 through anti-seepage curtain 13 and seepage dividing plate 12. During the period, the water level in the seepage tank 15 gradually decreases, and the water level in the seepage tank 16 remains constant. The water pressure changes at v...

Embodiment 3

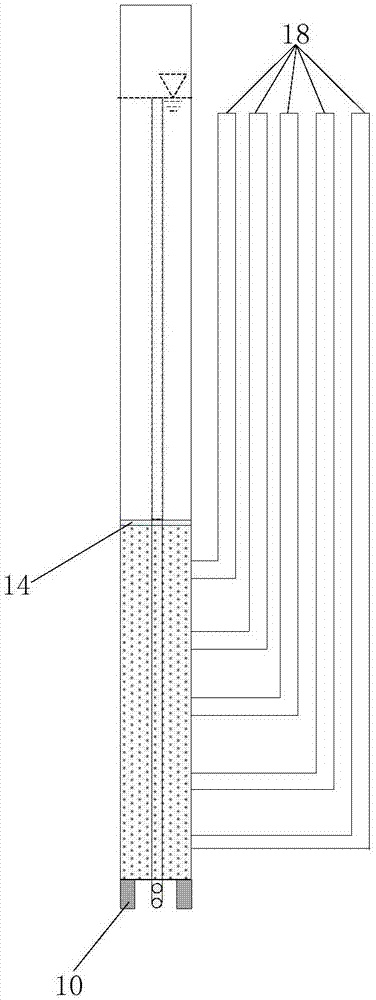

[0078] Example 3 Pumping test of complete well in confined water layer

[0079] see Figure 4, the water circulation sand tank test device used in the confined water seepage model of the present invention can simulate the complete well pumping test of the confined water layer. Its principle is: first lay test sand in sand tank, cover top cover plate 14 then, and seal with waterproof glue. Turn on the water pump 7, open the valves 5 and 6, the water flow is pumped out from the water tank 8, and enters the infiltration tank 15 through the inflow port 4. When the water level rises to the height of the overflow port 1, the water level does not rise any more, and the constant water head is maintained in the infiltration tank condition. The water in the seepage tank 15 enters the sand tank 17 through the seepage barrier 2 and the anti-seepage screen 3, and then flows into the seepage tank 16 through the seepage barrier 13 and the seepage barrier 12. Close the valve 9, so that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com