Compressor piston automatic production line monitoring system

An automated production line and monitoring system technology, applied in general control systems, control/adjustment systems, computer control, etc., can solve problems such as inability to use intelligence, lack of continuity, and production line stoppages, so as to facilitate inspection and analysis and improve The effect of product quality and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

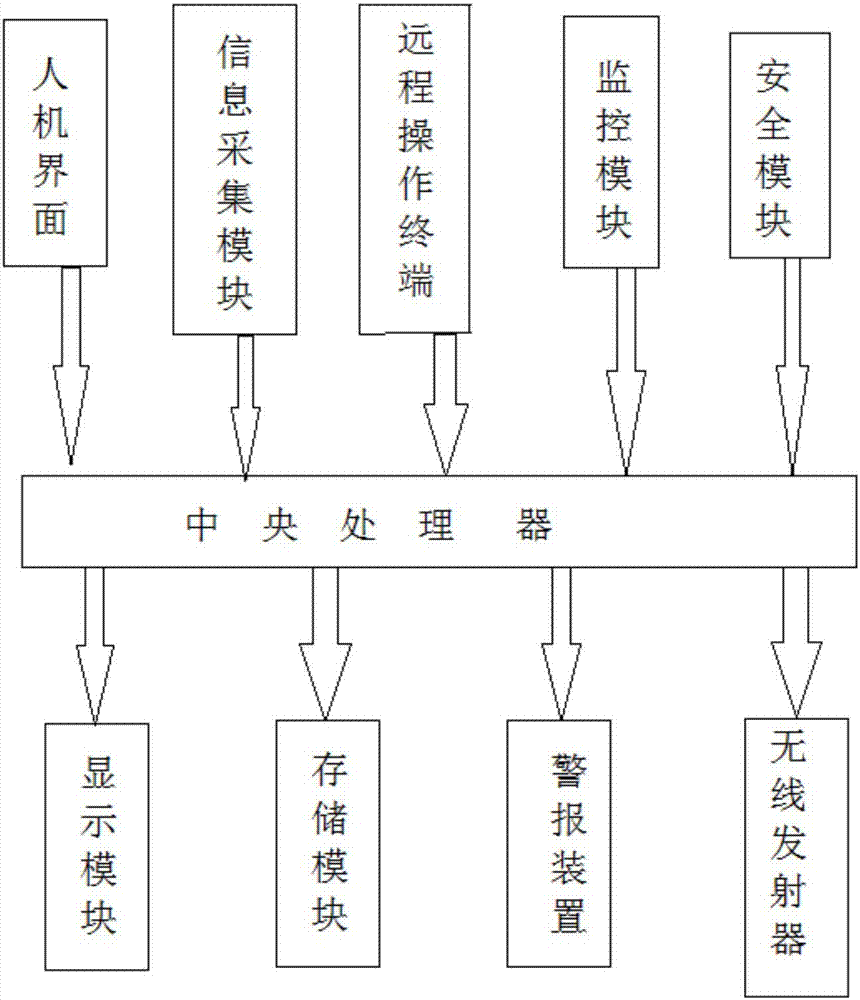

[0022] A compressor piston automatic production line monitoring system, including a central processing unit, the input end of the central processing unit is connected with a man-machine interface, an information collection module, a remote operation terminal, a monitoring module and a safety module, and the output end of the central processing unit is connected with a display module , storage module, alarm device and wireless transmitter; the information collection module is used to collect displacement sensor information, angle sensor information, operating parameters of each machine tool equipment, product parameter information and principle parameter information of the entire production line. The remote operation terminal is connected with the CNC system of milling machine and lathe, the control system of boring machine, the control system of cylindrical lathe, the control system of centerless grinding machine and the workpiece transmission system.

[0023] The monitoring mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com