Efficient dissociation and sorted collection method for each component of waste lithium ion batteries

A technology for lithium-ion batteries and waste lithium batteries, which is applied in the field of high-efficiency dissociation and classification recovery of components of waste lithium-ion batteries, can solve the problems of low recovery efficiency and complicated sorting process, and achieve high-efficiency recovery, simple operation, and high efficiency effect of dissociation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

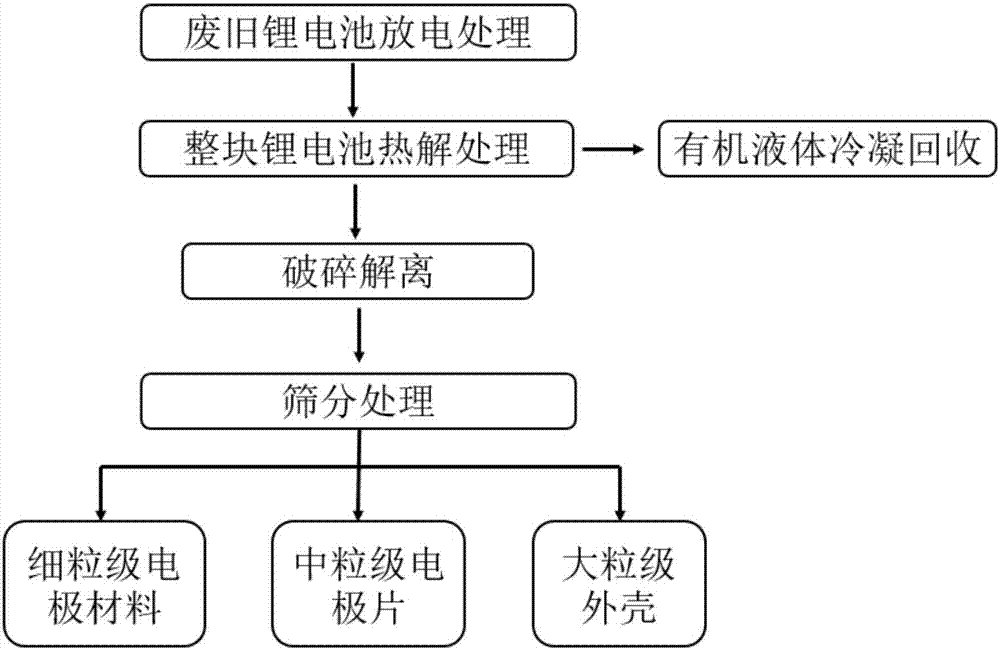

[0019] Please refer to figure 1 As shown, it shows a preferred embodiment of the present invention, a method for efficient dissociation and classification recovery of various components of a waste lithium ion battery, including the following steps:

[0020] (1) Discharging treatment of waste and old lithium batteries: discharge the waste and old lithium ion batteries to obtain uncharged waste lithium batteries, laying the foundation for the subsequent treatment process; in this embodiment, put the waste and old lithium ion batteries into a certain Discharge treatment is carried out in the discharge battery of the ion concentration solution.

[0021] (2) Pyrolysis treatment of the whole lithium battery: thermally decompose the discharged waste lithium battery as a whole to realize the decomposition and removal of the electrolyte, diaphragm and binder, and then realize the full dissociation of the electrode material and the electrode sheet, and The recovery of the organic pyrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com