Single inductor bridgeless APFC circuit based on IGBT module

A single inductance and circuit technology, applied in high-efficiency power electronic conversion, electrical components, output power conversion devices, etc., can solve the problems of large space occupation, high cost, and unsatisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

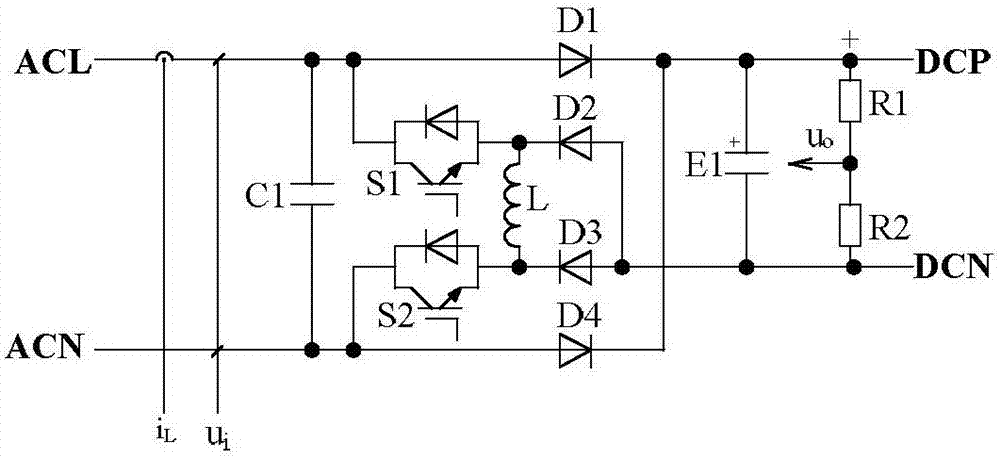

[0047] A single-inductance bridgeless APFC circuit based on an IGBT module of the present invention includes an AC filter capacitor C1, a first IGBT module S1, a second IGBT module S2, an inductor L, a first power diode D1, a second power diode D2, a second The third power diode D3, the fourth power diode D4, the DC filter capacitor E1, the first voltage dividing resistor R1, and the second voltage dividing resistor R2.

[0048] The anode of the first power diode D1, the first end of the AC filter capacitor C1, and the collector of the first IGBT module S1 are connected to the live wire of the power supply to form an input voltage and input current sampling terminal, and the input current i can be sampled at this point L and input voltage u i .

[0049] The anode of the fourth power diode D4, the second end of the AC filter capacitor C1 and the collector of the second IGBT module S2 are connected to the neutral line of the power supply.

[0050] The emitter of the first IGBT...

Embodiment 2

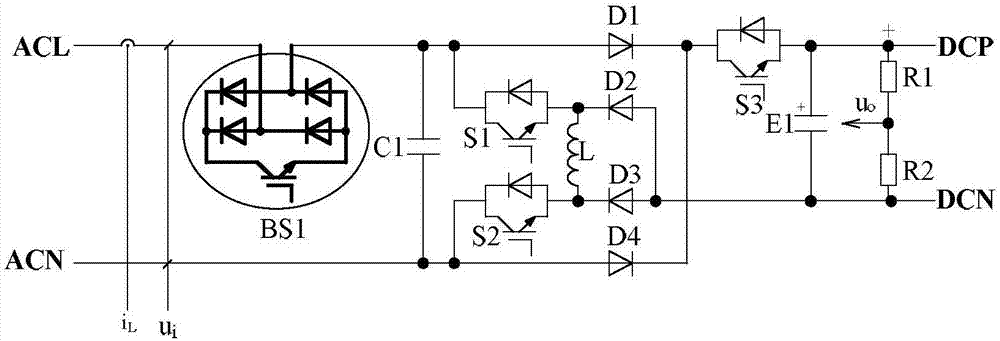

[0073] A single-inductance bridgeless APFC circuit based on IGBT modules of the present invention includes an AC filter capacitor C1, a first IGBT module S1, a second IGBT module S2, a third IGBT module S3, an inductor L, a first power diode D1, and a second IGBT module. The second power diode D2, the third power diode D3, the fourth power diode D4, the DC filter capacitor E1, the first voltage dividing resistor R1, the second voltage dividing resistor R2, and the bidirectional switch BS1.

[0074] The first end of the bidirectional switch BS1 is connected to the live wire of the power supply to form an input voltage and input current sampling end, at which point the input current i can be sampled L and input voltage u i .

[0075] The second end of the bidirectional switch BS1 is connected to the first end of the AC filter capacitor C1 , the collector of the first IGBT module S1 and the anode of the first power diode D1 .

[0076] The anode of the fourth power diode D4, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com