Multifunctional stainless steel converter

A stainless steel, multi-functional technology, applied in the field of chromium-based stainless steel and nickel-chromium-based smelting, can solve problems such as large fluctuations in composition and inability to adapt to smelting tasks, reducing contact area, flexible production organization and scheduling, and strong reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

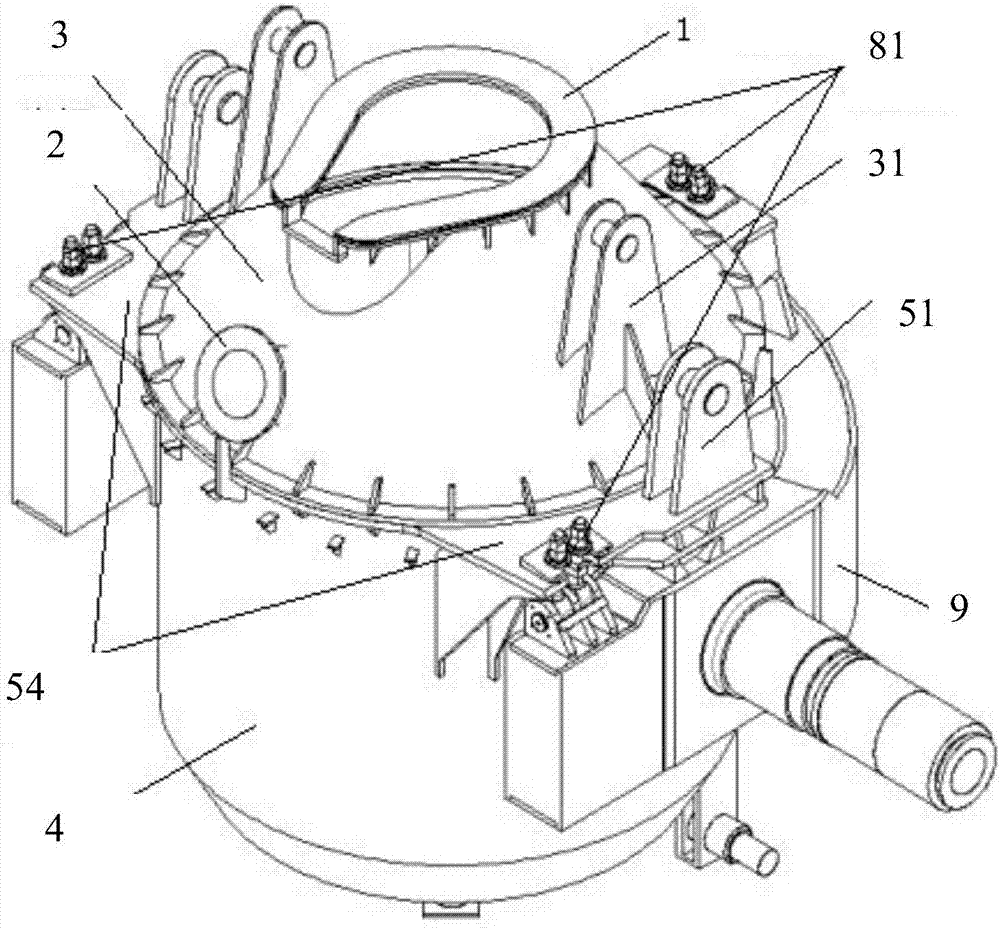

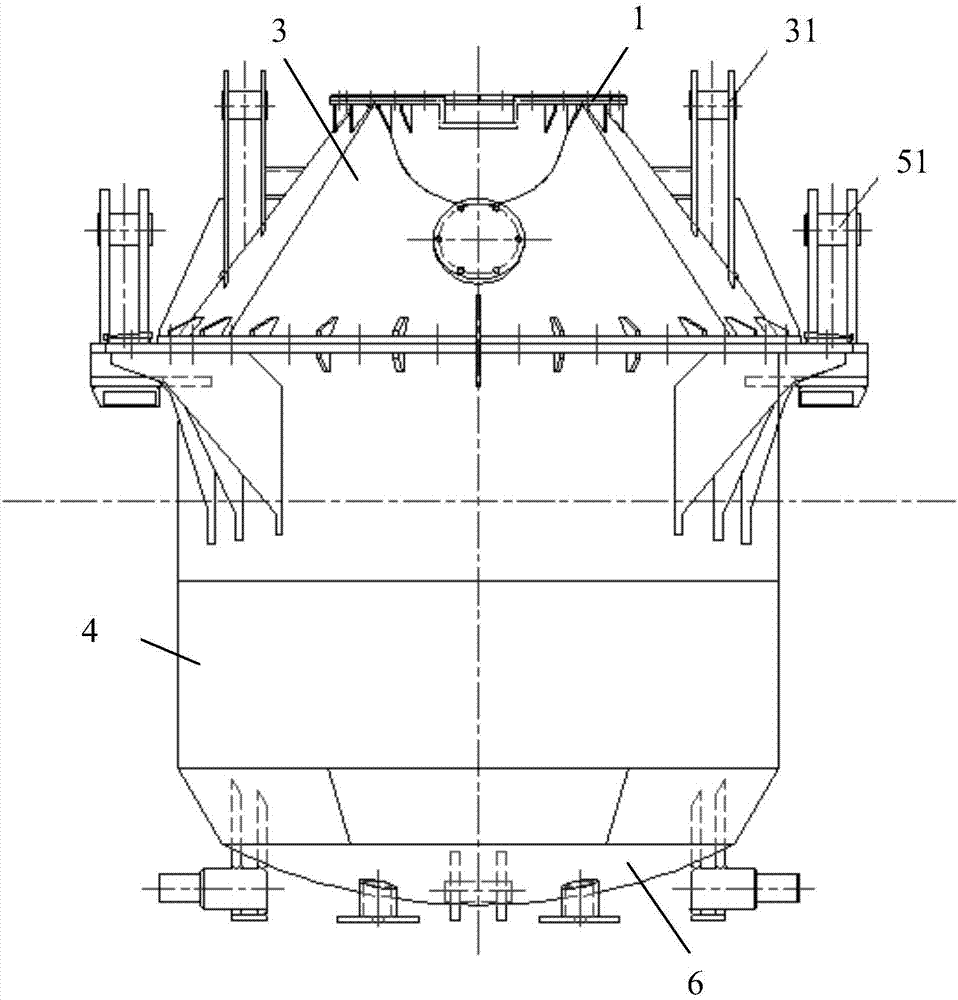

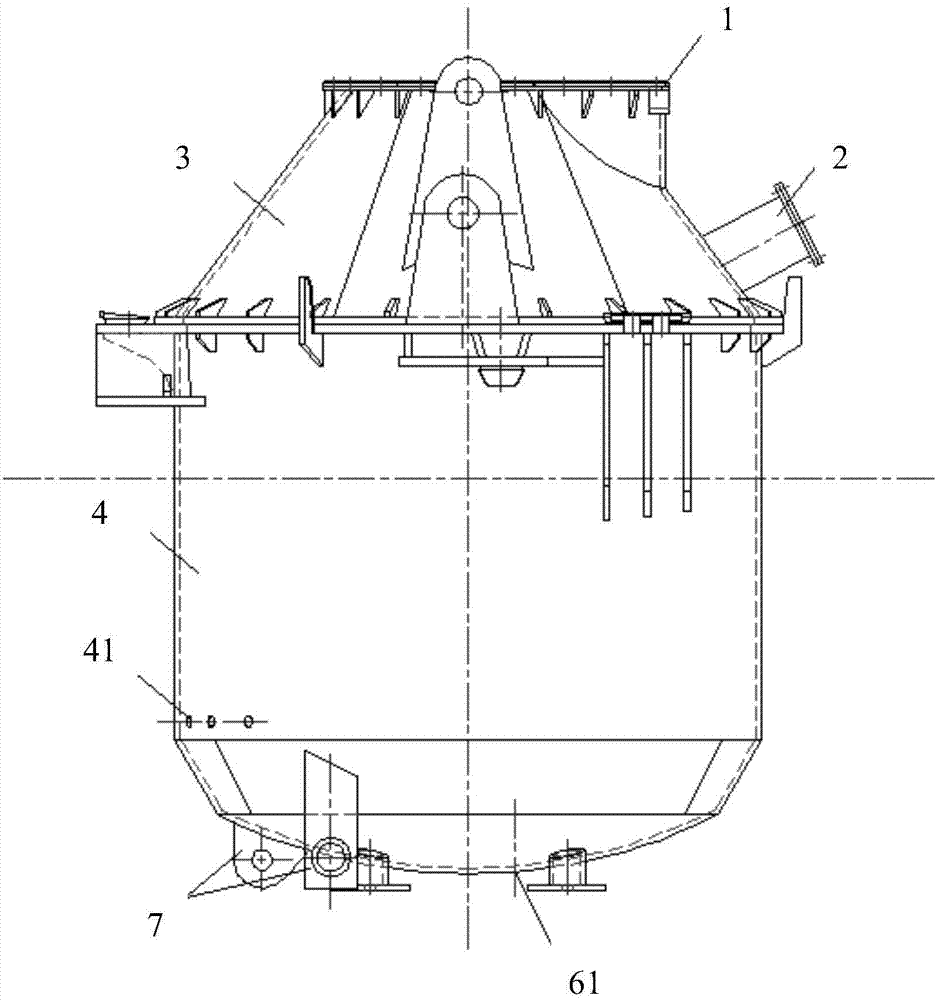

[0019] In order to better understand the purpose, structure and function of the present invention, a multifunctional stainless steel converter of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0020] Such as Figure 1 to Figure 5 As shown, it shows a multifunctional stainless steel converter of the present invention, the converter includes a pretreatment component and a refining component, the pretreatment component is used for pretreatment and smelting of molten iron containing nickel and / or chromium, and the converter containing the refining component Provide high-quality semi-steel, including the tapping hole 2 set on the side wall of the furnace cap 3 and the bottom tuyere 61 set on the furnace bottom 6. The tapping hole 2 is used for slag blocking and tapping to realize the separation of steel slag and prevent different The steel slag of the nature enters the next process, the bottom blowing valve station b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com