Method for repairing abnormal color spots and color patterns of nylon cloth

A processing method and technology of nylon cloth, applied in the processing of textile materials, dyeing method, liquid/gas/steam textile processing and other directions, can solve the problems of poor cloth quality, prolonged bleaching and dyeing time, good quality, etc., to reduce water consumption and sewage discharge, saving dyeing water, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

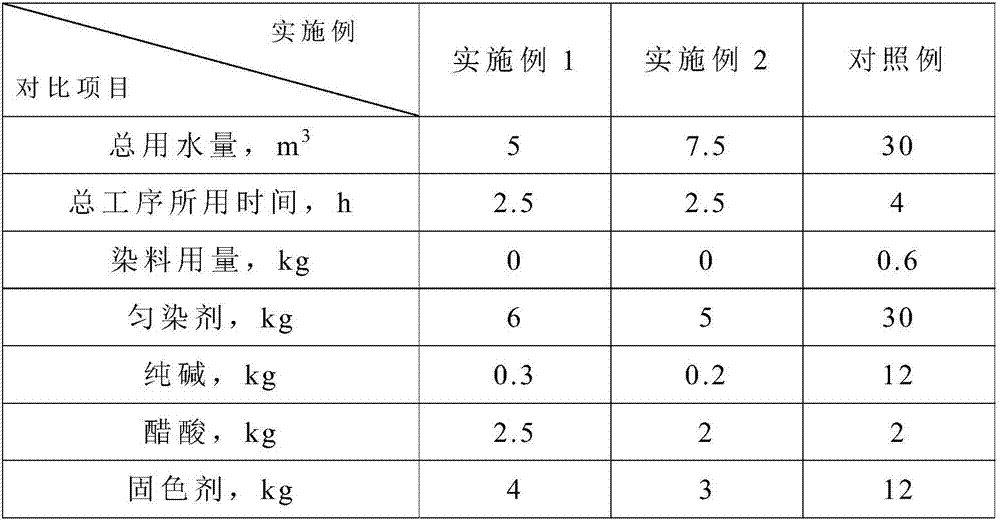

Embodiment 1

[0028] The repair treatment of nylon cloth with some color spots on the surface includes the following steps: rewinding abnormal nylon gray cloth → color repair treatment → color fixing treatment → dehydration treatment → drying mid-inspection → finalizing treatment, the details are as follows:

[0029] Step 1, rewinding the abnormal nylon gray fabric: rewind the nylon gray fabric with abnormal color pattern to the cloth car;

[0030] Step 2, color repairing treatment: the color repairing equipment adopts Jiangsu Yizheng TMH128-220 overflow jigger, according to the water meter, add 5g / L Pingpingjiao (Guangdong Zhonglian Fine Chemical Co., Ltd., industrial product), 0.3g / L L soda ash (Guangdong Zhongben Fine Chemical Co., Ltd., industrial product), to obtain the color repair solution, immerse the nylon gray cloth described in step 1 in the color repair solution, the bath ratio is 1:10, and the temperature is raised to 110 °C at a heating rate of 0.4 ° C / min. ℃, keep warm for 30...

Embodiment 2

[0036] The repair treatment of nylon cloth with some color spots on the surface includes the following steps: rewinding abnormal nylon gray cloth → color repair treatment → color fixing treatment → dehydration treatment → drying mid-inspection → finalizing treatment, the details are as follows:

[0037] Step 1, rewinding the abnormal nylon gray fabric: rewind the nylon gray fabric with abnormal color pattern to the cloth car;

[0038] Step 2, color correction treatment: the color correction equipment adopts Jiangsu Yizheng TMH128-220 overflow jigger, according to the water meter, add 3g / L Pingpingjiao (Guangdong Zhonglian Fine Chemical Co., Ltd., industrial product), 0.2g / L L soda ash (Guangdong Zhongbang Fine Chemical Co., Ltd., industrial product), to obtain the color repair solution, immerse the nylon gray cloth described in step 1 in the color repair solution, the bath ratio is 1:15, and the temperature is raised to 100 °C at a heating rate of 0.6 °C / min. ℃, keep warm for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com