Modified thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane and elastomer technology, applied in the field of modified thermoplastic polyurethane elastomer and its preparation, can solve the problems of poor compatibility, multi-step, doping of compatibilizers, etc., and achieve the effect of improving hardness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

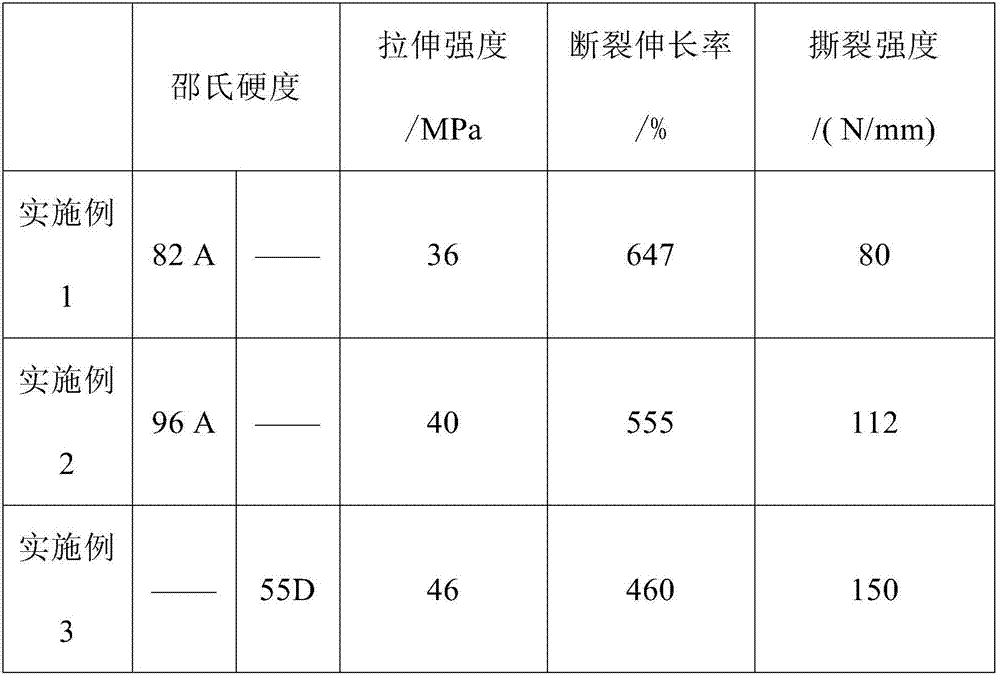

Examples

Embodiment 1

[0024] A modified thermoplastic polyurethane elastomer is made from raw materials comprising the following parts by weight:

[0025] 70.0 parts of styrene grafted polyester polyols;

[0026] 24.4 parts of diphenylmethane diisocyanate MDI;

[0027] Butanediol 5.6 parts.

[0028] The preparation method of modified thermoplastic polyurethane elastomer comprises the following steps:

[0029] (1) Vacuum dehydration of styrene-grafted polyester polyol and butanediol at 120°C and 100°C for 3-5h respectively;

[0030] (2) The diphenylmethane diisocyanate of the dried styrene graft modified polyester diol that takes 70 parts by weight, 24.4 parts joins in the reaction vessel, is heated up to at 260r / min stirring speed 80°C, vacuum reaction for 2h;

[0031] (3) Release the vacuum, add 5.6 parts of dried chain extender butanediol into the reaction vessel, stir rapidly, the temperature of the material gradually rises to 120°C, the viscosity increases significantly, stop stirring, and ...

Embodiment 2

[0033] Modified thermoplastic polyurethanes, made from raw materials comprising the following percentages by weight:

[0034] 60.0 parts of styrene grafted polyester polyols;

[0035] 31.6 parts of diphenylmethane diisocyanate MDI;

[0036] Butanediol 8.4 parts.

[0037] The preparation method of modified thermoplastic polyurethane elastomer comprises the following steps:

[0038] (1) Vacuum dehydration of styrene-grafted polyester polyol and butanediol at 120°C and 100°C for 3-5h respectively;

[0039] (2) Weighing 60 parts by weight of dried styrene-grafted polyester polyol and 31.6 parts of diphenylmethane diisocyanate were added to the reaction vessel, and the temperature was raised to 80° C. at a stirring speed of 260 r / min. Vacuum reaction for 2h;

[0040] (3) Release the vacuum, add 8.4 parts of dried chain extender butylene glycol into the reaction vessel, stir rapidly, the temperature of the material gradually rises to 120°C, the viscosity increases significantly,...

Embodiment 3

[0042] Modified thermoplastic polyurethanes, made from raw materials comprising the following percentages by weight:

[0043] Styrene grafted polyester polyol 50.0

[0044] Diphenylmethane diisocyanate MDI 38.7

[0045] Butanediol 11.3

[0046] The preparation method of modified thermoplastic polyurethane elastomer comprises the following steps:

[0047] (1) Vacuum dehydration of styrene-grafted polyester polyol and butanediol at 120°C and 100°C for 3-5h respectively;

[0048] (2) Weighing 50 parts by weight of dried styrene-grafted polyester polyol and 38.7% diphenylmethane diisocyanate into the reaction vessel, heated up to 80°C at a stirring speed of 260r / min, Vacuum reaction for 2h;

[0049] (3) Release the vacuum, add 11.3 parts of dried chain extender butylene glycol into the reaction vessel, stir rapidly, the temperature of the material gradually rises to 120°C, the viscosity increases significantly, stop stirring, and pour it into a polytetrafluoroethylene tray , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com