Flame-retardant single-faced tape and preparation method thereof

A flame retardant and flame retardant adhesive technology, which is applied in the field of flame retardant single-sided tape and its preparation, can solve the problems of poor flame retardant performance of the tape, and achieve convenient production and operation, high adhesion, and excellent weather resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The present invention also discloses a method for preparing a single-sided adhesive tape with flame retardant properties, comprising the following steps:

[0023] (1) Preparation of flame retardant coating: first add flame retardant to the dispersion solvent methyl ethyl ketone and stir and disperse with a mixer for 25-35 minutes, then add PU resin to stir and disperse; after stirring fully, use a grinder to fully grind and filter twice Finally, flame retardant coatings are obtained.

[0024] (2) Preparation of flame retardant glue: Dilute and disperse the curing additive with a solvent at a ratio of 1:1, then add it to the acrylic adhesive for stirring, then add the flame retardant and stir evenly and let it stand for 25-35 minutes to obtain the flame retardant glue .

[0025] (3) Apply the flame-retardant coating on the transparent base film, bake it at 85°C-95°C for 2.5-3.5 minutes for curing, and after curing, put it into a drying room at 45°C-55°C for 23-25h Dryi...

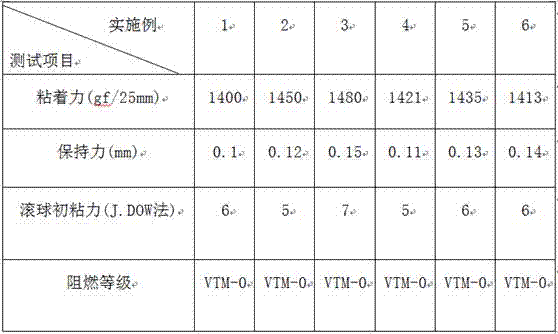

Embodiment 1

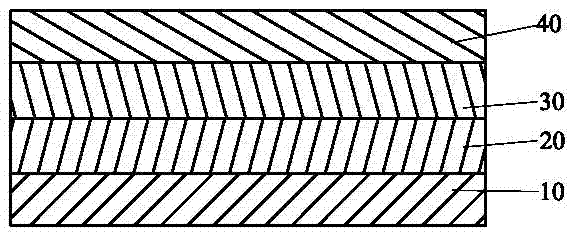

[0029] A single-sided adhesive tape with flame-retardant performance includes a transparent base film 10, a flame-retardant coating 20, a flame-retardant adhesive layer 30 and a single-sided release film 40.

[0030] The flame retardant coating 20 is coated on the surface of the transparent base film 10, the flame retardant adhesive layer 30 is coated on the surface of the flame retardant coating 20, and the single-sided release film 40 is coated on the flame retardant adhesive layer 30 on the surface. Moreover, the transparent base film 10 is made of PET. The flame retardant coating 20 includes the following components by weight percentage: 25% of PU resin, 30% of flame retardant and 45% of dispersing solvent butanone; the thickness of the flame retardant coating is 5 μm. The flame retardant adhesive layer 30 includes the following components in weight percentage: 90% of acrylic adhesive, 8% of flame retardant and 2% of curing additive, and the thickness of the flame retarda...

Embodiment 2

[0037] A single-sided adhesive tape with flame-retardant performance includes a transparent base film 10, a flame-retardant coating 20, a flame-retardant adhesive layer 30 and a single-sided release film 40.

[0038] The flame retardant coating 20 is coated on the surface of the transparent base film 10, the flame retardant adhesive layer 30 is coated on the surface of the flame retardant coating 20, and the single-sided release film 40 is coated on the flame retardant adhesive layer 30 on the surface. Moreover, the transparent base film 10 is made of PET. The flame retardant coating 20 includes the following components in weight percent: PU resin 35%, flame retardant 10% and dispersion solvent butanone 55%; the thickness of the flame retardant coating is 10 μm. The flame retardant adhesive layer 30 includes the following components in weight percentage: 97% of acrylic adhesive, 2% of flame retardant and 1% of curing additive, and the thickness of the flame retardant adhesive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com