Air-combined steam quenching apparatus and method for rails

A quenching device and rail technology, applied in the field of heat treatment, can solve the problems of inability to obtain quenching hardness and depth of hardened layer, too fast quenching cooling speed, quenching cracks, and too deep hardened layer, etc., so as to reduce the investment in quenching equipment, increase the Large hardening depth and the effect of improving the structure of the rail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0026] The present invention also provides specific embodiments as follows:

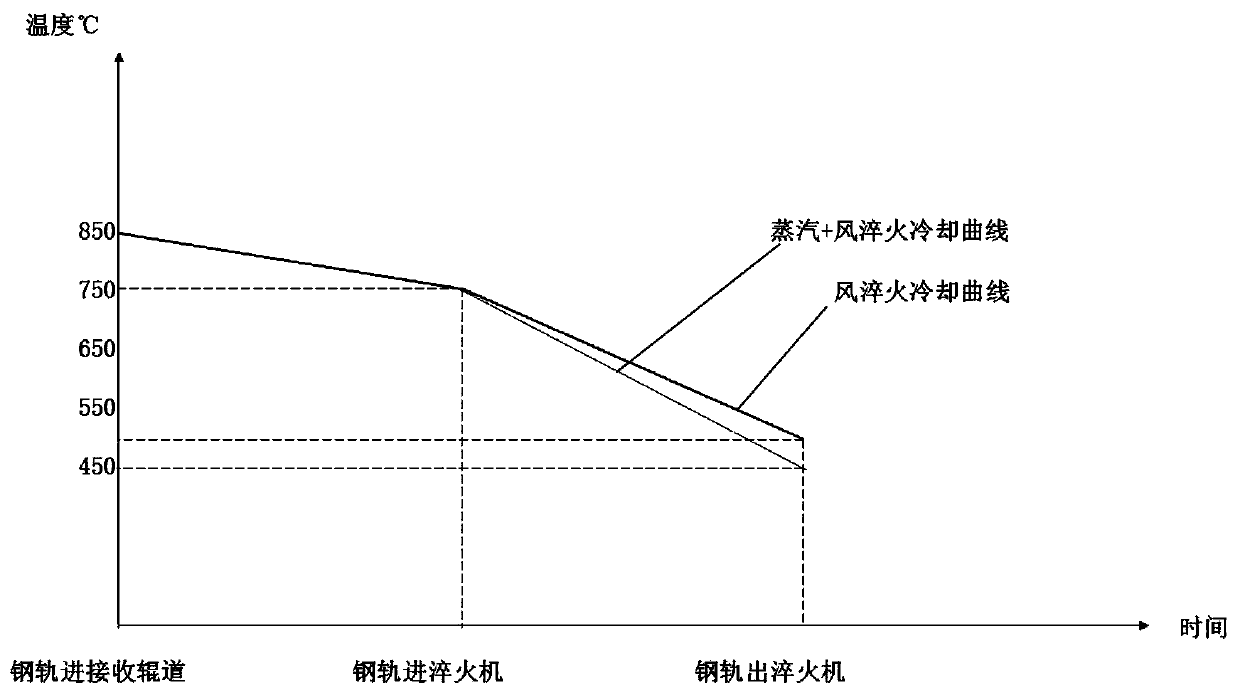

[0027] The 60AT rail test with steel type U75V was adopted, and pure air-cooled quenching and air+steam quenching were used respectively, and the test data were obtained as follows:

[0028] 1) Rail Surface Hardness

[0029] Table 1 Rail top surface hardness and rail tensile strength

[0030]

[0031] 2) Section hardness

[0032] Table 2 Hardness of rail section

[0033]

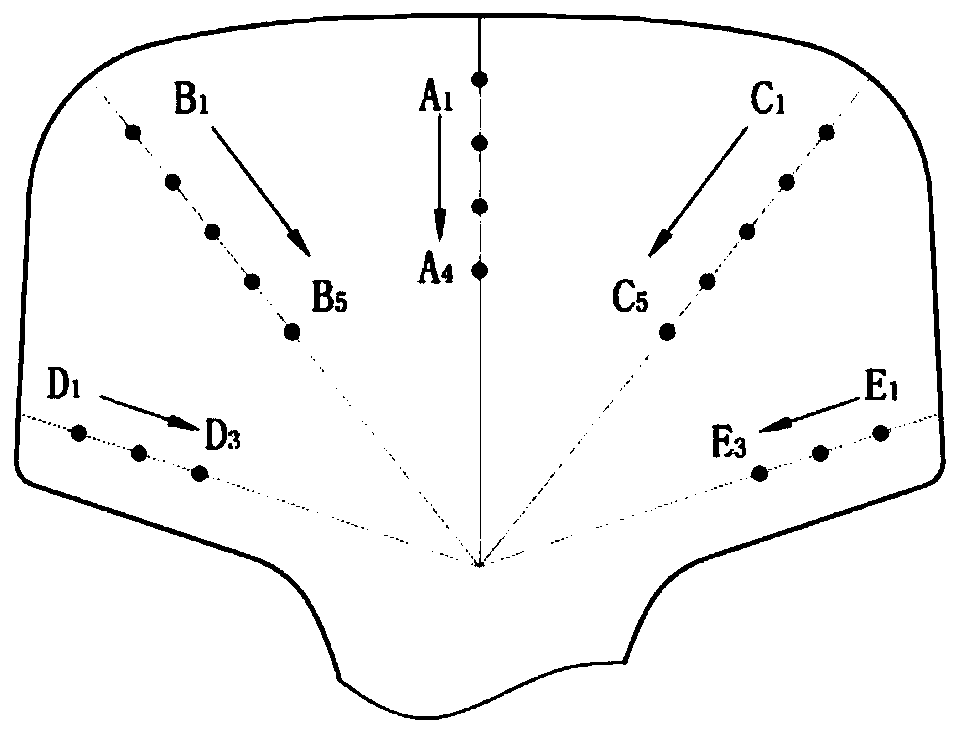

[0034] Rail section such as image 3 As shown, the distance between the first point and the surface is 5 mm, and the distance between other points is 5 mm. The distance between the D and E lines and the mandible is 5 mm, and the B and C lines are the angle bisectors of A, D and A, E lines.

[0035] 3) Microstructure

[0036] The microstructure of the full section of the air-quenched rail should be pearlite structure, containing a small amount of ferrite, and some rails contain a small amount of martensite, bainite and gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com