Preheating body for preheating combustion-supporting air by using flame radiation and heat energy equipment with preheating body

A technology of combustion-supporting air and flame radiation, which is applied in the field of combustion equipment and components, and can solve problems such as large heat loss, low thermal efficiency, and low thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

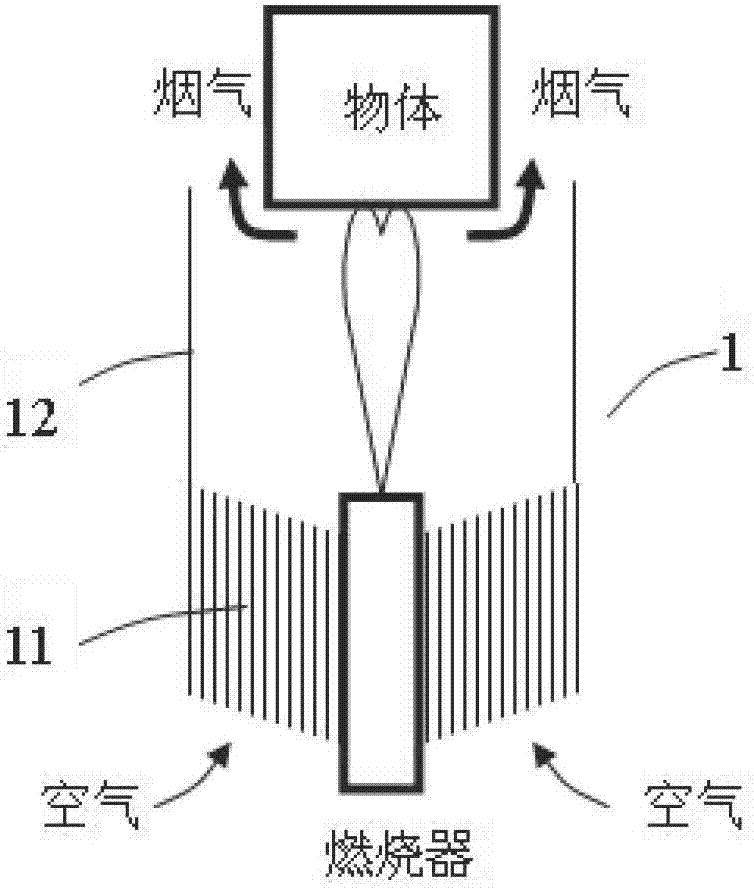

[0051] Such as figure 2 Shown is a schematic diagram of a spiral-wound preheater in the present invention. see figure 2 , The spiral-wound preheater 1 includes a spiral-wound portion 11 and a cylinder 12 . The height of the spiral coil portion 11 is slightly lower than the height of the applied burner head; the height of the cylinder 12 is greater than or equal to the height of the object to be heated away from the burner head. The height of the spiral-wound preheater 1 is the sum of the height of the spiral-wound portion 11 and the height of the cylinder 12 . The spiral coil portion 11 has a through hole in the middle, and the through hole in the middle is adapted to the outer diameter of the burner head.

[0052] The spiral-wound preheater 1 is made of copper foil according to the following method:

[0053] (1) Buy copper foil from the market. The thickness specification of the copper foil sheet can be selected from single zero foil (0.1 to 0.01mm); the width specific...

Embodiment 2

[0079] The space around the burner head of many combustion heating equipment is narrow, and it is difficult to install the spiral-wound preheater given in Example 1. The most common of these combustion heating equipment is the gas stove used in ordinary household kitchens. There is very little space between the head and the bottom of the pan.

[0080] Aiming at these heating equipments where it is difficult to install a spiral-wound preheater, the present invention provides another flat radiation-finned preheater that utilizes flame radiation to preheat the combustion-supporting air, such as Figure 5 with 6 shown. The flat radiation-finned preheater 2 includes a cylinder 22, the bottom of which is supported on the cooking range, and the top of which supports a round-bottomed frying pan. A series of air inlets 23 are evenly opened on the wall of the bottom edge of the cylinder 22 around the circumference direction, and a series of smoke outlets 24 are evenly opened around t...

Embodiment 3

[0097] This embodiment is a high-position radiation-finned preheater used for a frying pan. see Figure 7 , The high-position radiating finned preheater 3 includes a cylinder 32, the bottom of which is supported on the cooktop, and the top of which is fixedly or detachably mounted with an annular plate 35. The middle part of the ring plate 35 has an opening matched with the outer diameter of the frying pan, and the two ears of the frying pan are supported on the edge of the opening in the middle part of the ring plate 35 . A series of air inlets 33 are evenly opened around the circumference on the wall at the bottom edge of the cylinder 32 , and a series of smoke outlets 34 are evenly opened around the circumference on the wall at the middle of the cylinder 32 . A series of long radiation fins 311 and short radiation fins 312 are arranged inside the cylinder 32 . The radial arrangement mode of these radial fins is identical with embodiment 2 ( Figure 7 The A-A sectional vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com