Steel rolling heating furnace waste heat steam recycling system and recycling method

A waste heat steam, heating furnace technology, applied in lighting and heating equipment, furnaces, waste heat treatment and other directions, can solve the problems of difficult to effectively meet the real-time adjustment requirements of load conditions, many energy conversion times, and high equipment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

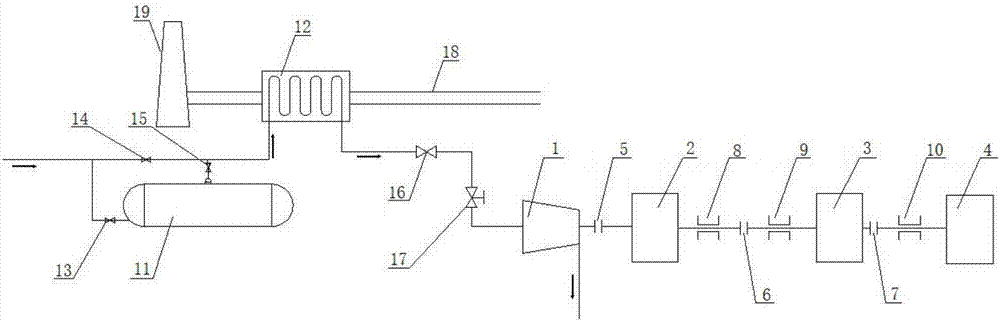

[0056] combine figure 1 , the waste heat steam recovery and utilization system of the steel rolling heating furnace in this embodiment includes: a steam input pipeline, which is drawn from the vaporization cooling system of the steel rolling heating furnace; a screw expander 1, the steam inlet of the screw expander 1 and The steam input pipeline is connected; the load device 3, the output end of the screw expander 1 can be connected with the load device 3; wherein, the load device 3 can be a blower for the air preheater of the steel rolling heating furnace, a flue gas induced draft fan, a circulating water pump or other Screw expander 1 and motor 4 are coaxially connected rotating equipment; motor 4, the output end of motor 4 can be connected with load device 3, wherein, motor 4 is a frequency conversion motor with frequency conversion machine. Specifically in this embodiment, the output end of the screw expander 1 is connected to the load device 3 through the transmission 2; ...

Embodiment 2

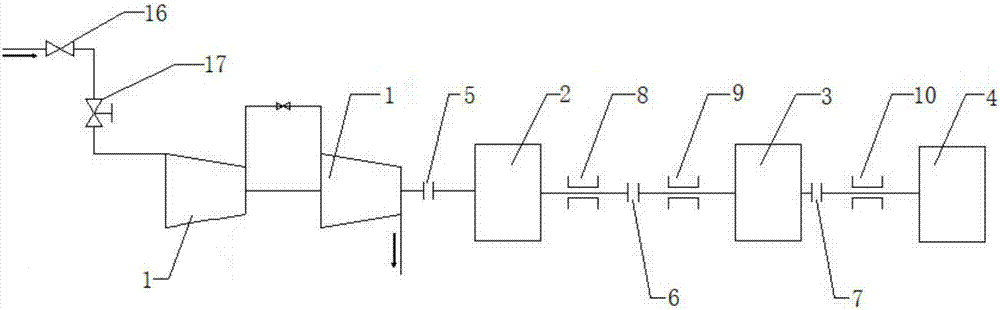

[0083] The structure of the waste heat steam recovery and utilization system of the steel rolling heating furnace in this embodiment is basically the same as that of the embodiment 1. Furthermore: due to the low expansion efficiency of the screw expander 1, when the steam temperature and pressure parameters are high (the steam quality is relatively high) Hershey), can be used as figure 2 In the series mode shown, that is, the number of screw expanders 1 in this embodiment is two, the two screw expanders 1 are connected coaxially, and the steam channels of the two screw expanders 1 are connected in series (one screw expander 1 The steam outlet of the expander 1 is connected to the steam inlet of another screw expander 1); the steam discharged from the flue gas superheater 12 first enters a screw expander 1 for initial expansion work, and then enters another screw expander Expansion work in the machine 1, and the two screw expanders 1 jointly drive the load equipment 3 to opera...

Embodiment 3

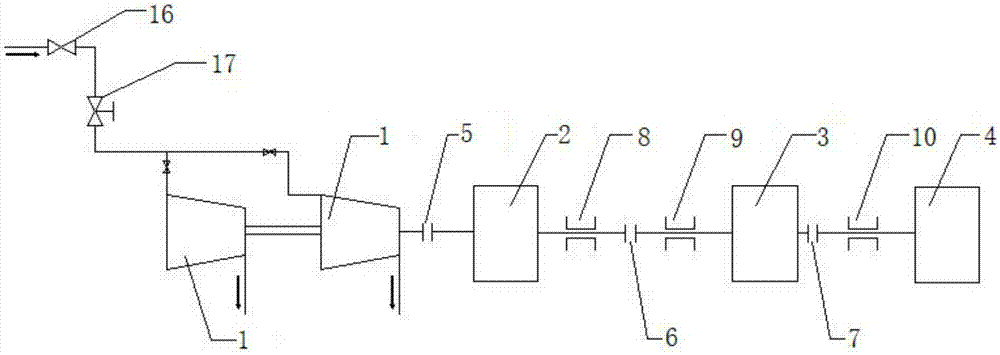

[0085] The structure of the waste heat steam recovery and utilization system of the steel rolling heating furnace in this embodiment is basically the same as that of Embodiment 1. Further: when the steam output of the steel rolling heating furnace vaporization cooling system is relatively large, the following can be used: image 3 The parallel connection mode shown, that is, the number of screw expanders 1 in this embodiment is two, the two screw expanders 1 are connected coaxially, and the steam channels of the two screw expanders 1 are connected in parallel (that is, two The steam inlets of the two screw expanders 1 are respectively connected with the steam input pipes); the steam discharged from the flue gas superheater 12 is respectively sent to the two screw expanders 1 to expand and perform work through the pipes, and the two screw expanders 1 jointly drive the load The equipment 3 is in operation, so as to improve the working efficiency of the screw expander 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com