Mechanically-controllable cracking device with high attenuation coefficient

A technology with high attenuation and coefficient, applied in measurement devices, material analysis by electromagnetic means, instruments, etc., can solve the problem of difficult to have high attenuation coefficient and long service life at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] specific implementation plan

[0032] The present invention will be described in more detail below in conjunction with the accompanying drawings.

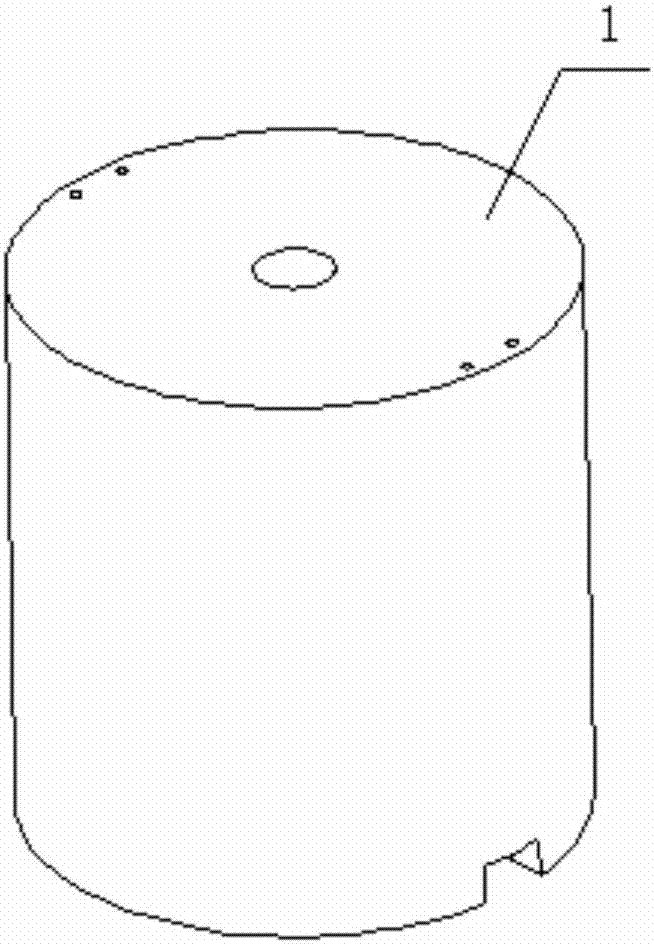

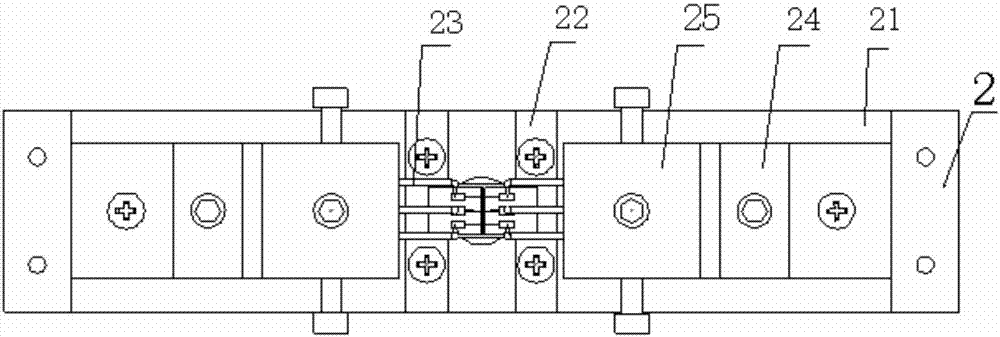

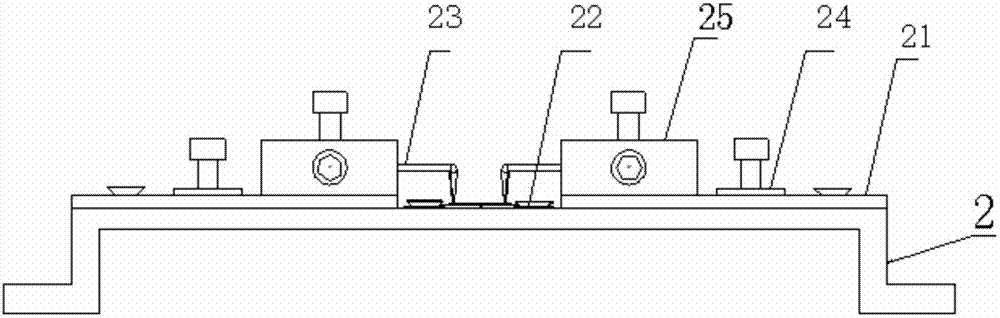

[0033] see Figure 1-10 , the embodiment of the present invention includes a skeleton base 1 , a probe device 2 , a microchip 3 , and a stepping motor 4 .

[0034] The skeleton base 1 is a cylindrical base made of stainless steel, such as figure 1 shown. Used to assemble the probe device 2 and the microchip 3 to reduce vibration.

[0035] The probe device 2 has a multilayer structure, such as figure 2 with 3Shown: supporting structure of aluminum alloy material 21, chip fixing structure of epoxy glass fiber cloth substrate material 22, silver needle 23, flexible insulating structure made of polyester-coated flexible copper clad laminate 24, external electrode structure made of PTFE 25.

[0036] The microchip 3 is prepared on a silicon substrate through film cleaning, spin coating polyimide 31, coating, exposure and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com