Visual automatic point-to-point method for smart substation

An intelligent substation, automatic point-to-point technology, applied in electrical components, circuit devices, information technology support systems, etc., can solve the problems of centralized debugging work time, high work intensity, and no integrated system configuration, etc. Automate closed-loop business flow, improve work efficiency and speed, and realize the effect of automated closed-loop verification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings.

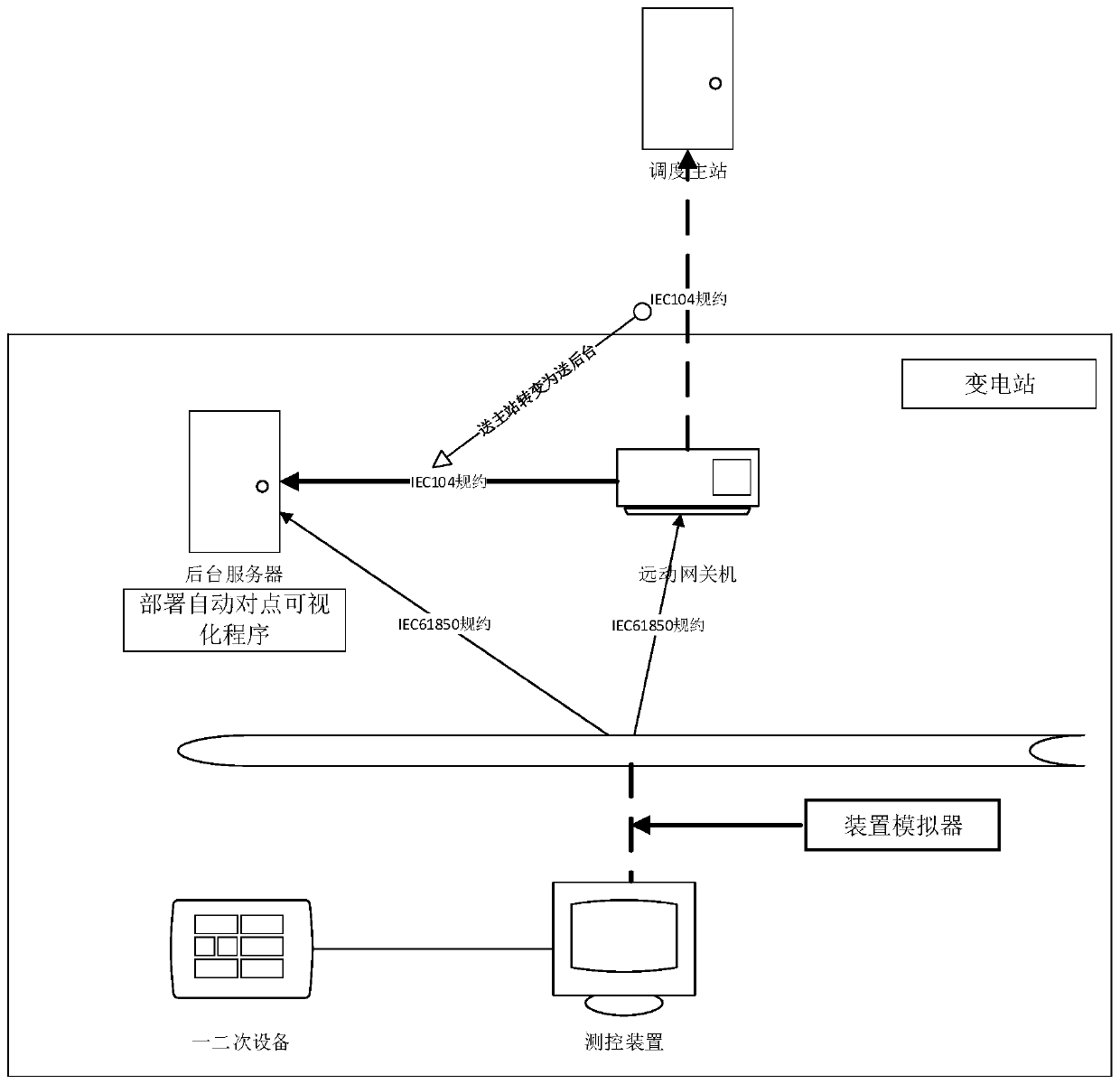

[0050] Such as figure 1 As shown in the figure, the visual automatic point-to-point system of the smart substation includes a background server, a telecontrol gateway, a measurement and control device and a device simulator;

[0051] Information communication between the telecontrol gateway and the background server is carried out through the IEC104 protocol;

[0052] The measurement and control device and the device simulator are connected to the information interaction device (communication bus) of the intelligent substation; the information interaction device communicates with the background server and the remote control gateway through the IEC61850 protocol.

[0053] Without the cooperation of the dispatching master station, the automatic closed-loop verification of the internal business of the substation can be realized; if the device simulator is used instead of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com