A planter hole sowing device

A seeder and hole sowing technology, which is applied to the parts of the seeder, sowing, and fertilization devices, etc., can solve the problems of poor seeding performance of the seeding device of the hole seeder, large amount of seed waste in large-scale operations, and high rate of missed sowing, and achieve The effect of reducing the missed seeding rate, reasonable structure design, and high seeding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

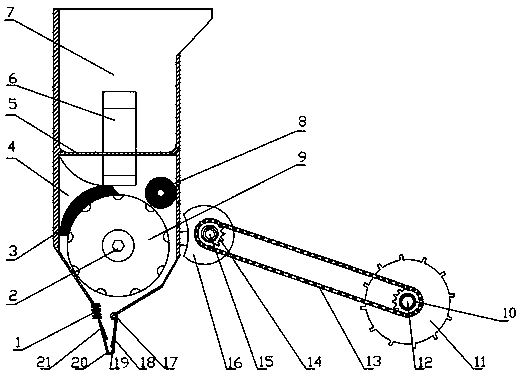

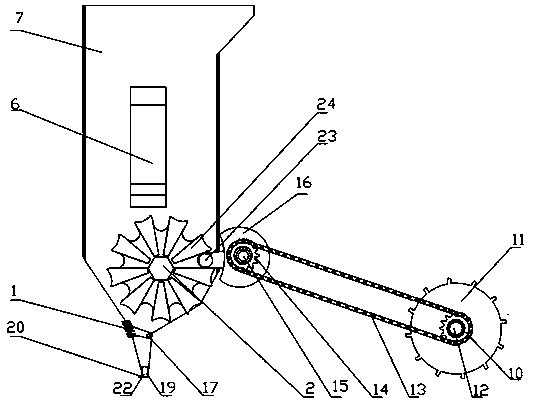

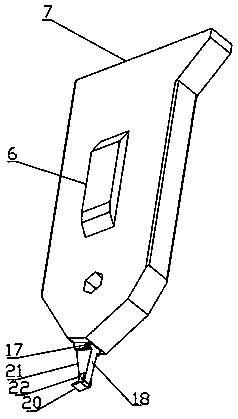

Embodiment 1

[0018] Embodiment 1: as Figure 1-Figure 3 As shown, a hole sowing device for a seeder includes a folding rubber layer 1, a seeding disk shaft 2, a partition brush layer 3, a gable part 4, a seed box partition 5, a seed guide groove 6, a seed box 7, and a brush Roller 8, seeding disc 9, sprocket wheel 10. Ground wheel 11, ground wheel shaft 12, cylindrical roller chain 13, sprocket 14, sprocket shaft 15, dial 16, pin shaft 17, leading seed plate 18, pin shaft 19. Movable baffle 20, rear seed guide plate 21, guard plate 22, round pin 23, sheave 24;

[0019] The seed box 7 is divided into upper and lower parts, and the lower part in the middle is separated by a seed box partition 5. The welding part of the seed box partition 5 and the seed box 7 adopts a large fillet transition, and the 6 inlets of the seed guide groove are arranged on the seed box partition. The upper part of the plate 5, the outlet is arranged at the bottom of the seed box dividing plate 5; The welded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com