High temperature-resistant fireproof sealing material

A sealing material and high-temperature-resistant technology, which is applied in the direction of layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problem of single function, etc., and achieve the effects of excellent comprehensive performance, enhanced structural strength, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

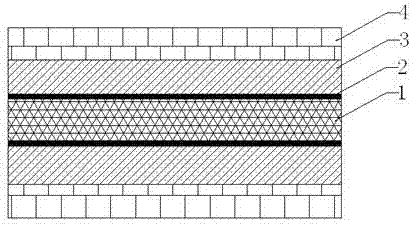

[0016] A high-temperature-resistant fire-proof sealing material, including a reinforced skeleton 1, a high-temperature-resistant layer 2 is respectively attached to both sides of the reinforced skeleton 1, and a fire-resistant sealing layer 3 and an insulating layer 4 are sequentially compounded on the outside of the high-temperature-resistant layer 2; The thickness ratio of the reinforcing frame 1, the high temperature resistant layer 2, the fireproof sealing layer 3 and the insulating layer 4 is 1:0.2:3:0.5.

[0017] Wherein, the reinforcing skeleton 1 is a carbon fiber and glass fiber mixed reinforced polytetrafluoroethylene layer, wherein the mixing ratio of the carbon fiber and glass fiber is 1:1.

[0018] The high temperature-resistant layer 2 is a flexible graphite layer, specifically a flexible graphite layer impregnated with an anti-oxidation impregnating agent, wherein the anti-oxidation impregnating agent is a mixed solution with a mass concentration of 30%, which is...

Embodiment 2

[0022] A high-temperature-resistant fire-proof sealing material, including a reinforced skeleton 1, a high-temperature-resistant layer 2 is respectively attached to both sides of the reinforced skeleton 1, and a fire-resistant sealing layer 3 and an insulating layer 4 are sequentially compounded on the outside of the high-temperature-resistant layer 2; The thickness ratio of the reinforcing skeleton 1, the high temperature resistant layer 2, the fireproof sealing layer 3 and the insulating layer 4 is 2:0.5:5:1.

[0023] Wherein, the reinforcing skeleton 1 is a carbon fiber and glass fiber mixed reinforced polytetrafluoroethylene layer, wherein the mixing ratio of the carbon fiber and glass fiber is 3:1.

[0024] The high temperature-resistant layer 2 is a flexible graphite layer, specifically a flexible graphite layer impregnated with an anti-oxidation impregnating agent, wherein the anti-oxidation impregnating agent is a mixed solution with a mass concentration of 35%, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com