A plug-removing and plug-restraining agent and a method for plug-removing and plug-suppressing in heavy oil production

A technology of plugging removal and plugging agent, which is applied in the field of plugging removal and suppression agent and plugging suppression in heavy oil production, and can solve the problems of low freezing point, poor asphaltene dissolution effect, and poor effect of precipitates with high asphaltene content, etc. , to achieve the effects of inhibiting the formation of blockages, good dissolution and removal effects, and obvious effects of blockage removal and blockage suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1~ Embodiment 15-1 and comparative example 1-1~ comparative example 15-1

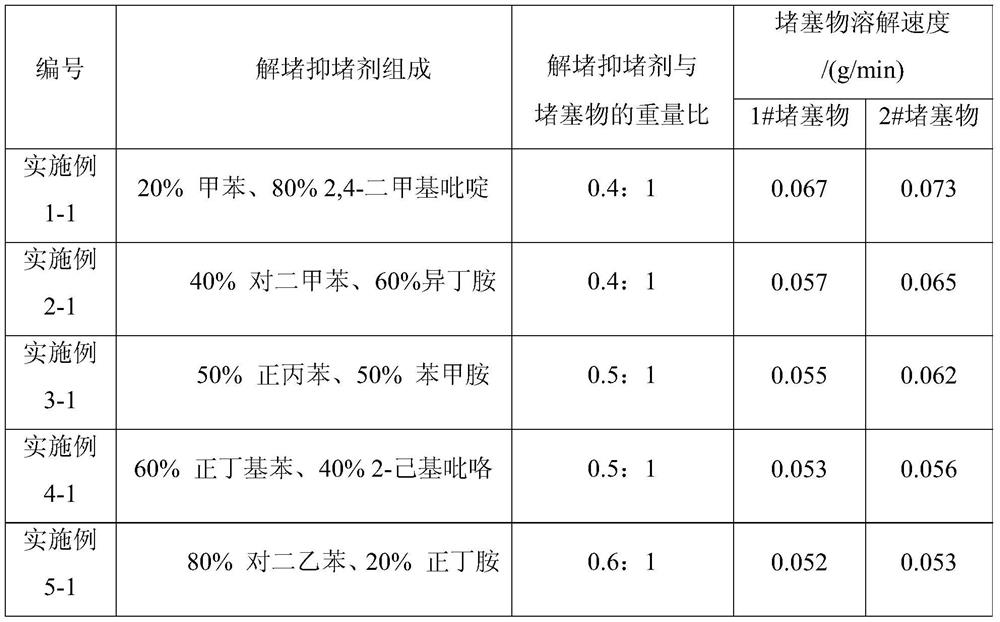

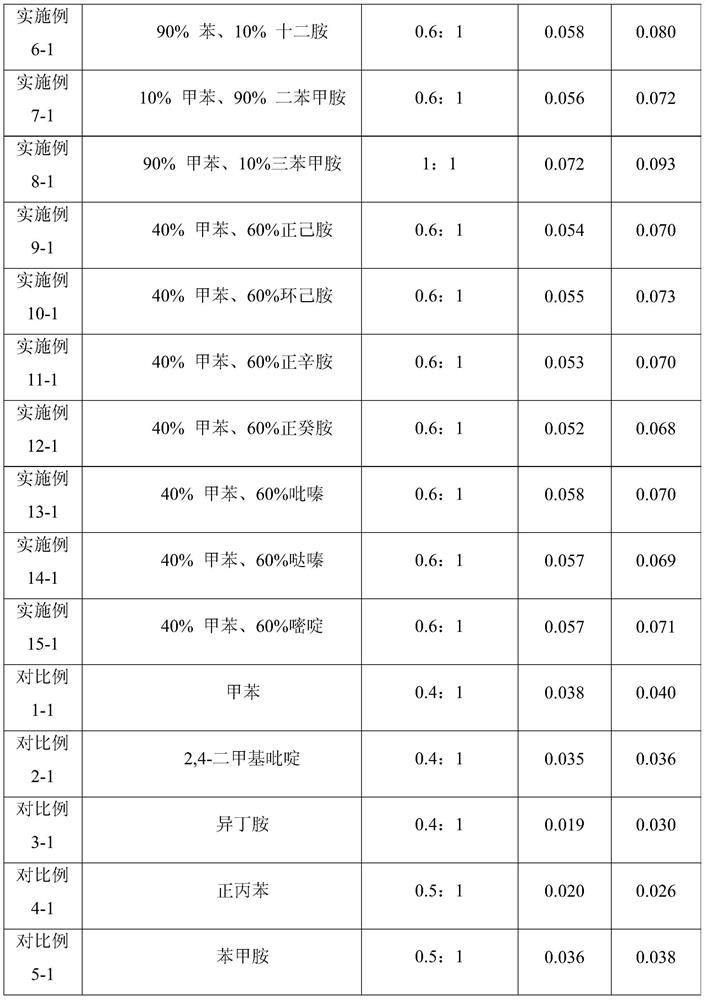

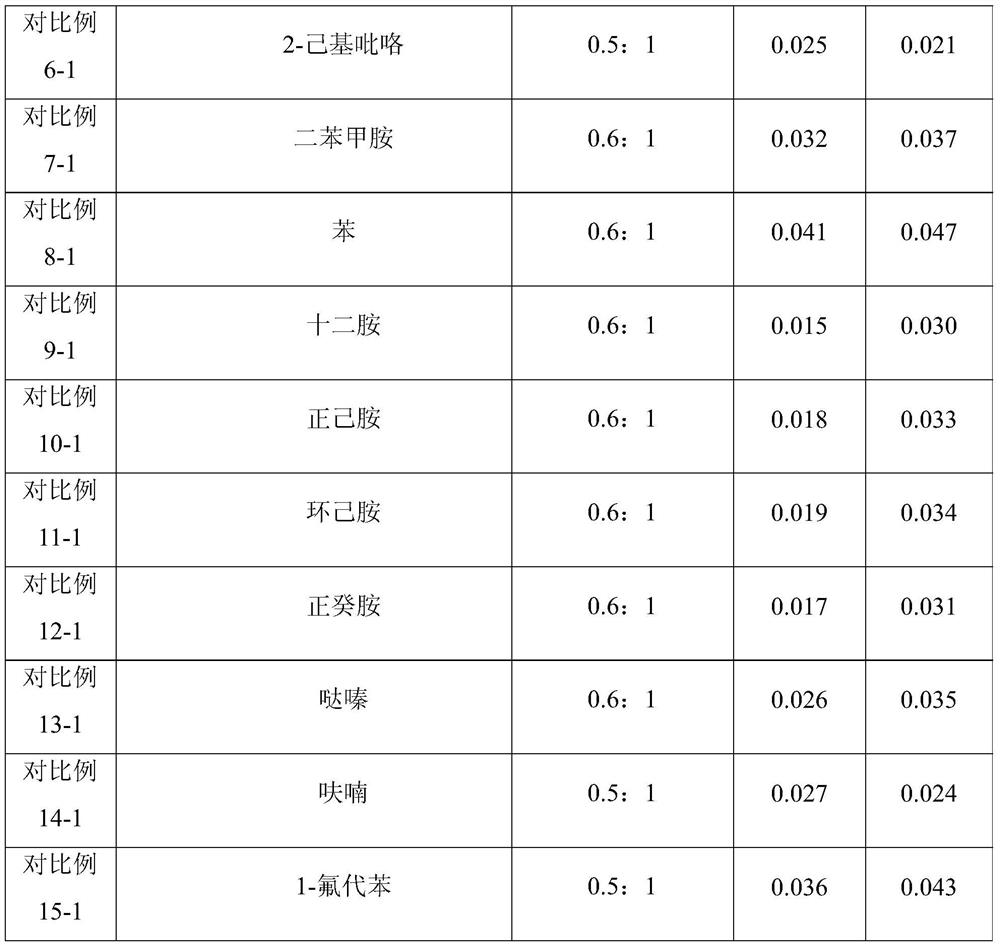

[0046] The examples and comparative examples are used to illustrate the dissolving speed of the blockage by different blockage removal and blockage inhibitors.

[0047] As shown in Table 1, according to different components and proportions, the blocking release and blocking inhibitor was prepared, and 20 g of the blocking release and blocking inhibitor were weighed and added to different 50mL conical flasks, and then added to each conical flask to make For the spherical plug sample, close the bottle mouth, let it stand at a constant temperature of 50 ° C for 30 minutes, and then weigh the residual amount of the dried plug to calculate the dissolution rate. The experimental results are shown in Table 1.

[0048] Table 1

[0049]

[0050]

[0051]

[0052] From the results of the examples and comparative examples in Table 1, it can be seen that compared with the single component of aromatic hydrocarbons or nitrogen-containing organic compounds or furans or fluorine-con...

Embodiment 1-2~ Embodiment 15-2 and comparative example 1-2~ comparative example 15-2

[0054] The various examples and comparative examples are used to illustrate the amount of dissolving the blockages by different plugging-removing and blocking-inhibiting agents.

[0055] As shown in Table 2, according to different components and proportions, the blocking removal and blocking inhibitor was prepared, and 10 g of the blocking removal and blocking inhibitor were respectively weighed and added to different 100mL conical flasks. Stir at the rotating speed, and continuously add the blockage samples until the blockage cannot be dissolved, and calculate the total dissolved amount of the blockage that can be dissolved by each g of the blockage release and blockage inhibitor. The experimental results are shown in Table 2.

[0056] Table 2

[0057]

[0058]

[0059]

[0060] From the results of the examples and comparative examples in Table 2, it can be seen that compared with the single component of aromatic hydrocarbons or nitrogen-containing organic compounds...

Embodiment 1-3~ Embodiment 15-3 and comparative example 1-3~ comparative example 15-3

[0062] The various examples and comparative examples are used to illustrate the inhibitory effect of different plug-removing and plug-inhibiting agents on the formation of plugs.

[0063] As shown in Table 3, according to different components and proportions, the blocking release and blocking inhibitor was prepared, and 10 g of the blocking release and blocking inhibitor were respectively weighed and added to different 100mL conical flasks, and more than The 1# blockage with the saturated dissolved amount was stirred with a magnetic stirrer at 200rpm for 3h at 50°C to fully dissolve the blockage, and then the undissolved residue was filtered out with filter paper. Place the plugged filtrate in a closed volumetric flask, let it stand at a constant temperature of 50 °C, regularly observe whether there is precipitation at the bottom of the filtrate, and calculate the stability time of the plugged filtrate. The experimental results are shown in Table 3.

[0064] table 3

[0065]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com