Lakebed hardening structure

An integrated, foamed cement board technology, applied in the field of environmental engineering, can solve the problems of high cost of cleaning engineering and sludge transportation, easy scattering of sludge on the road, damage to the surrounding environment, etc., to improve the landscape function and utilization value. , The effect of improving lake water quality and preventing seepage loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

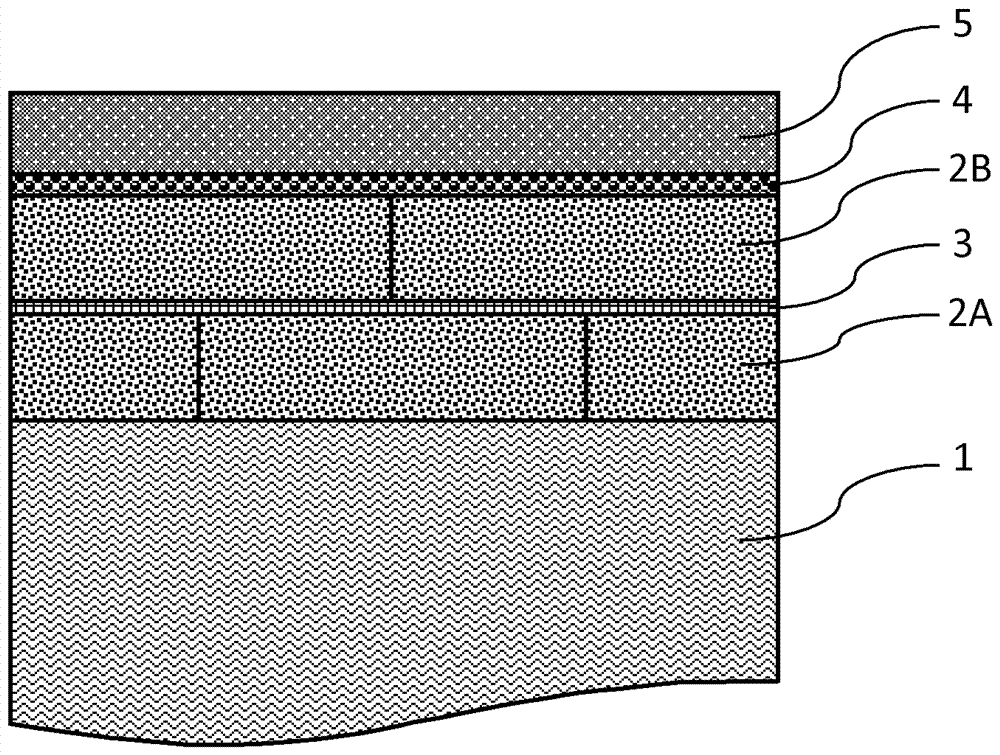

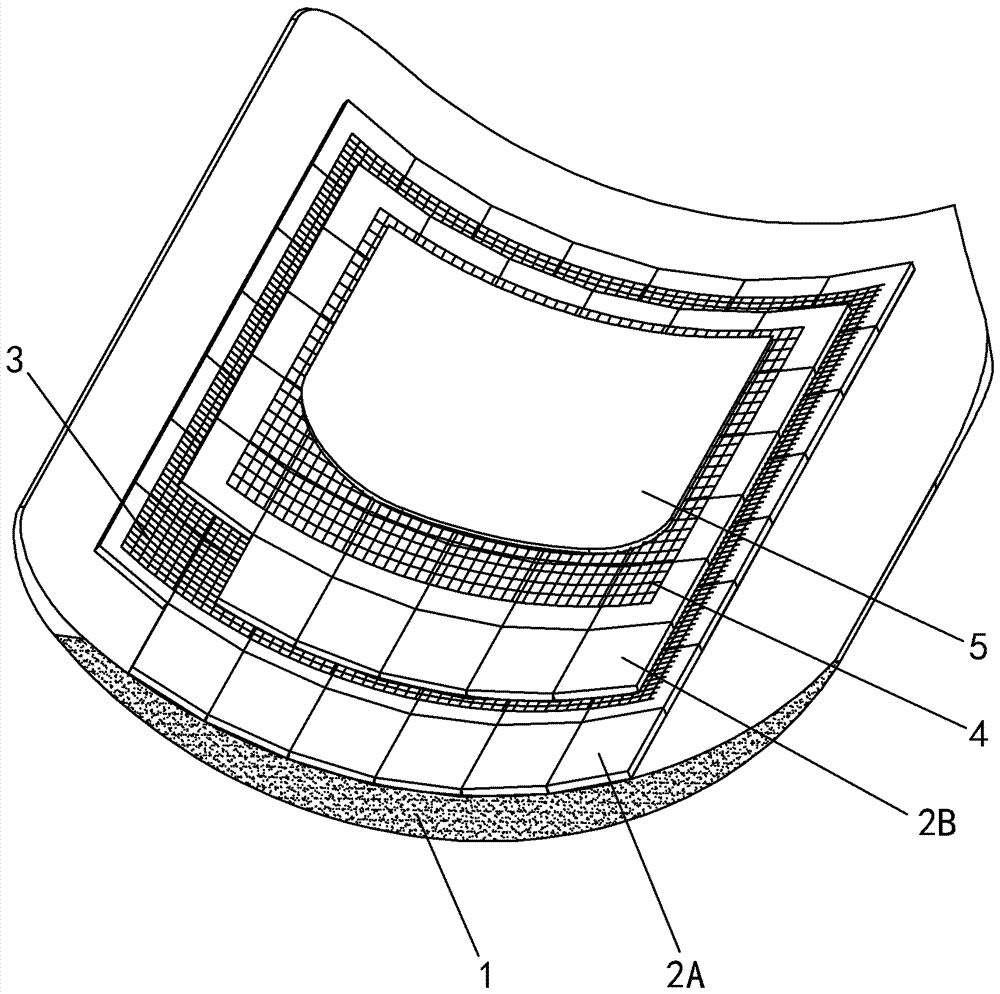

[0020] refer to figure 1 , figure 2 , The lake bottom hardening structure of the present invention is composed of a lower layer of foamed cement board (2A), a glass fiber mesh (3), an upper layer of foamed cement board (2B), a steel wire mesh (4) and a concrete layer (5). The lower layer of foamed cement board (2A) is laid directly on the lake bottom sludge (1), the glass fiber mesh (3) is laid between the lower layer of foamed cement board (2A) and the upper layer of foamed cement board (2B), and the lower layer is foamed The cement board (2A) and the upper foamed cement board (2B) are pasted together by mortar, the steel wire mesh (4) is laid on the upper foamed cement board (2B), and concrete is poured on the steel wire mesh (4) to form the most The upper concrete layer (5).

[0021] The lake bottom hardening structure of the present invention is constructed by on-site construction, and the lower layer of foamed cement board (2A) is directly laid on the lake bottom sludg...

Embodiment 2

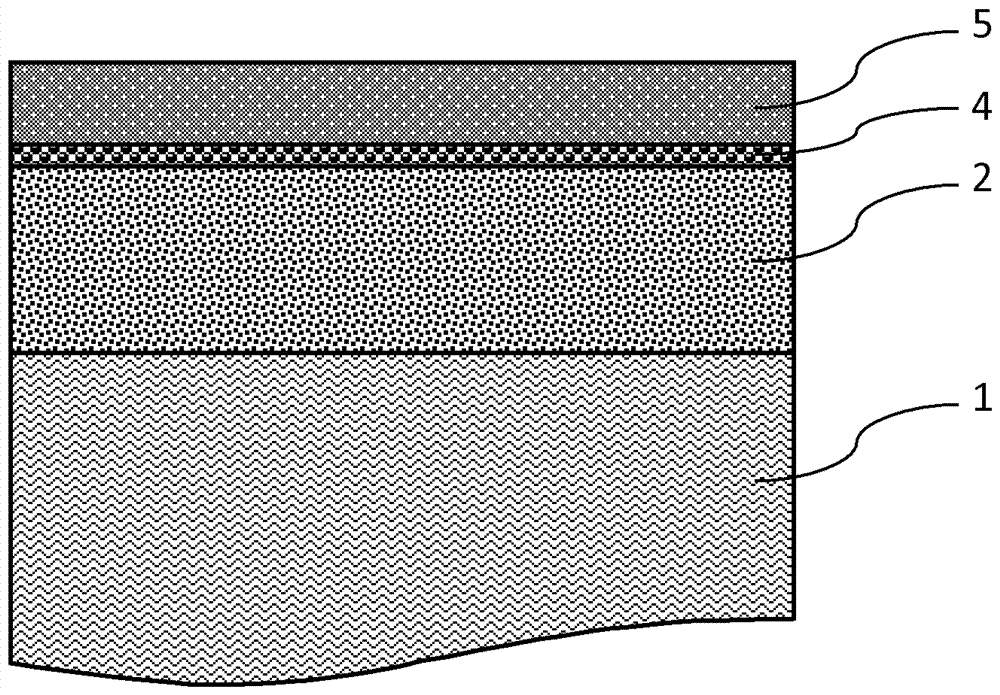

[0024] refer to image 3 , Figure 4 , the hardened structure at the lake bottom of the present invention is composed of a foamed cement layer (2), a steel wire mesh (4) and a concrete layer (5), the foamed cement layer (2) is directly built on the lake bottom sludge (1), and the steel wire mesh (4) ) is laid on the foamed cement layer (2), and concrete is poured on the steel wire mesh (4) to form the uppermost concrete layer (5).

[0025] The lake bottom hardening structure of the present invention is constructed by on-site construction. On the lake bottom sludge (1) after the water is drained, foam cement is directly poured on the lake bottom sludge (1) by using foam cement manufacturing equipment, and the foam cement is hardened. Then it becomes the supporting foam cement layer (2). Then the steel wire mesh (4) is laid on the foamed cement layer (2), and finally concrete is poured on it, and the concrete layer (5) is formed after the concrete is hardened, so that the hard...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com