Early-disassembling mechanism and formwork supporting system

A support column and roof technology, which is applied in the direction of formwork/template/work frame, building structure, and on-site preparation of building components, etc. problems such as the hidden danger of beam inclination, to achieve the effect of low erection difficulty, reduced construction cost and good support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

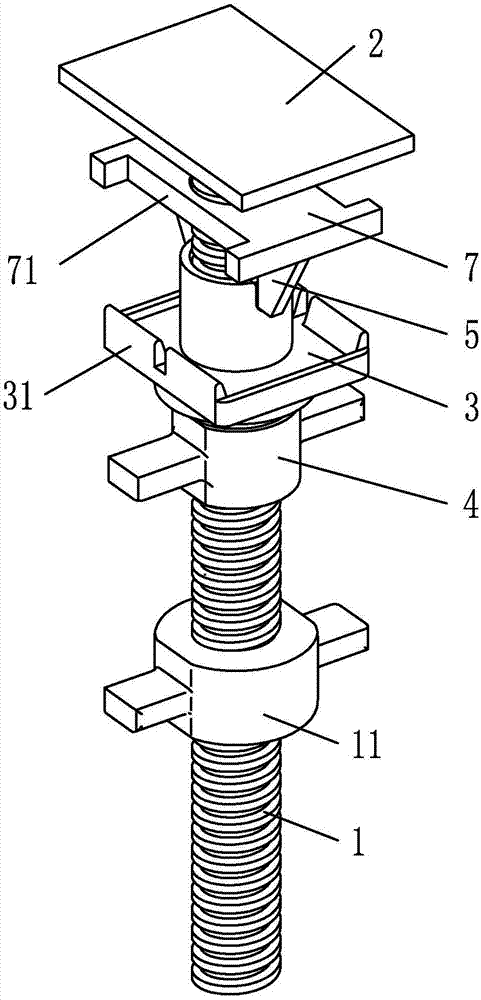

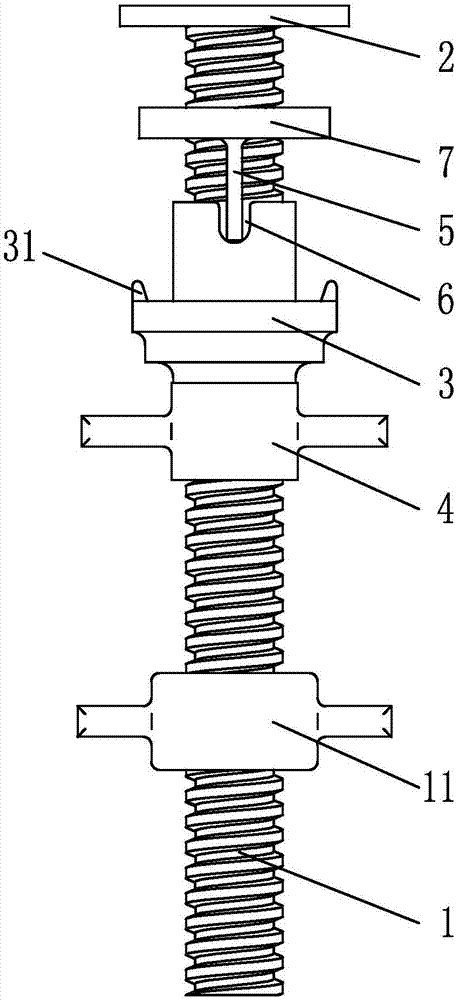

[0017] Example 1, see figure 1 , figure 2 , one An early dismantling mechanism, comprising a screw rod 1, a rectangular top plate 2, a rectangular early dismantling tray 3 and an early dismantling nut 4, and a screw rod lifting adjustment nut 11; the top plate 2 is fixedly connected to the top of the screw rod 1; on two parallel sides of the early dismantling tray 3 A positioning edge 31 is formed for the positioning of the main beam, and the early dismantling tray 3 is sleeved on the screw rod 1 through the conduit structure formed in the middle. Between pallet 3 and described screw rod 1, be formed with the guide structure that is used for removing pallet 3 lifting early, so that the rectangular four sides of pallet 3 and top plate 2 are correspondingly parallel; between described top plate 2 and pallet 3 early A positioning plate 7 is provided, and a main beam positioning structure is arranged on the positioning plate 7. The main beam positioning structure is formed by ...

Embodiment 2

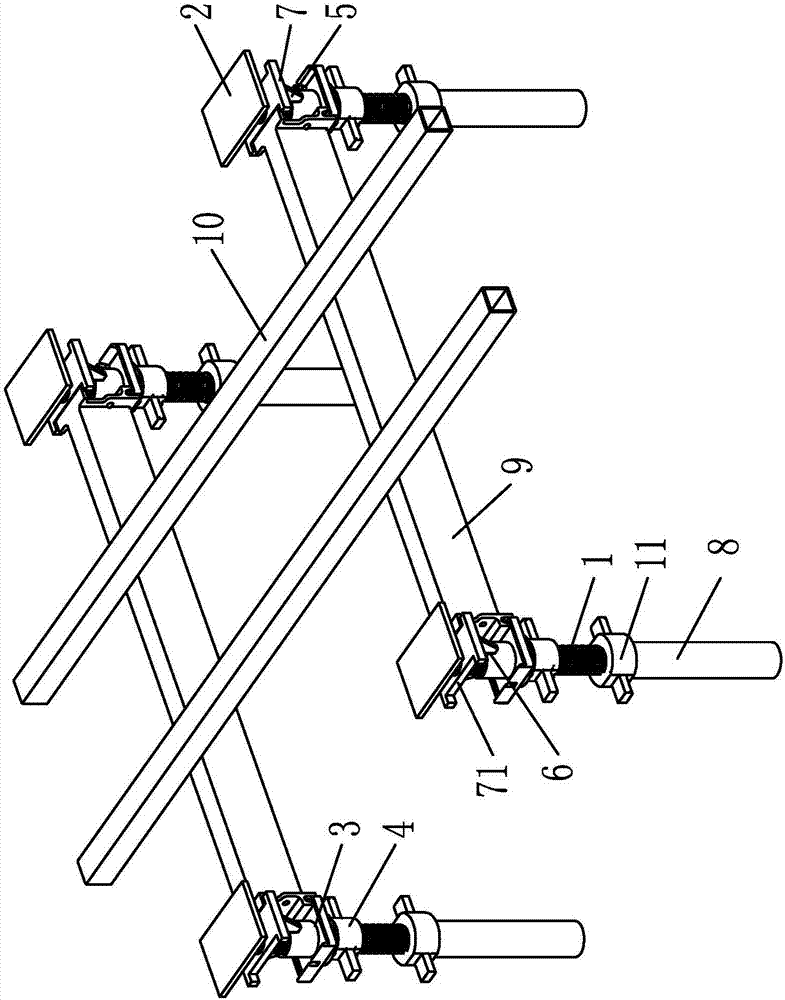

[0019] Example 2, see image 3 , combined with figure 1 , figure 2 , a formwork support system, including at least four even-numbered support columns 8, a plurality of support columns 8 are respectively arranged on the four corners of the corresponding rectangle, and the support columns 8 are provided with the early dismantling mechanism of Embodiment 1 of the present invention; wherein, The early removal tray 3 of the early removal mechanism is lapped with a main beam 9, and the positioning rib 31 on the early removal tray 3 cooperates with the U-shaped draw-in groove facing downwards at the lower opening of the main beam 9 beam ends to form the main beam 9 positioning, and the main beam 9 The upper part of the beam end is engaged in the rectangular opening 71 of the positioning plate 7, the top surface of the main beam 9 and the top surface of the positioning plate 7 are located in the same plane, and a secondary beam 10 is placed on two adjacent parallel main beams 9, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com