A novel laser galvanometer lens, a laser galvanometer and a film plating method

A technology of laser galvanometer and lens, applied in the field of new type of laser galvanometer lens, can solve the problems such as the limitation of the wavelength of the indicator light, only one working wavelength, no versatility, etc., and achieves weight reduction, excellent thermal conductivity, and improved response speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

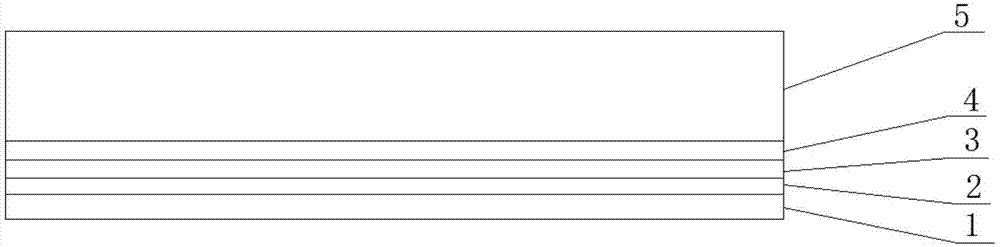

[0033] to combine figure 1 As shown, the present embodiment provides a novel laser vibrating mirror lens, which includes: a base film layer 1, an intermediate film layer, and a high-reflection film layer 5 arranged in sequence from bottom to top; the intermediate film layer includes: The first connection film layer 2, the Al film 3 and the second connection film layer 4 are arranged in sequence on the top. Due to the design of the intermediate film layer, compared with the traditional process, it can meet the demand for indicating light in any wavelength band of 400-700nm, making the lens more versatile. Moreover, the design of the high-reflection film layer 5 simultaneously satisfies the requirement of high reflection (reflection rate above 99.5%) of the frequency-doubled wavelength.

[0034] In this embodiment, the first connecting film layer 2 and the second connecting film layer 4 are used as connecting layers, and their purpose is to strengthen the bonding strength betwe...

Embodiment 2

[0048] The second embodiment also provides a laser vibrating mirror, which includes the novel laser vibrating mirror lens described in the first embodiment. Wherein, the number of the new-type laser vibrating mirror mirrors is two, one of which is applied to the vibrating mirror X, and the other is applied to the vibrating mirror Y. Among them, the angle change of the galvanometer Y-axis film is 25° to 52.5°, and the angle change of the X-axis film is 32.5° to 57.5°.

[0049] Specifically, combining figure 1 As shown, the new laser vibrating mirror lens includes: a base film layer 1, an intermediate film layer and a high-reflection film layer 5 arranged in sequence from bottom to top; the intermediate film layer includes: a first connecting film arranged in sequence from bottom to top layer 2, Al film 3 and second connecting film layer 4. Due to the design of the intermediate film layer, compared with the traditional process, it can meet the demand for indicating light in an...

Embodiment 3

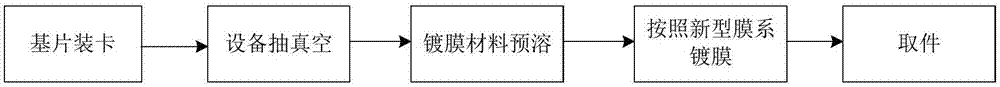

[0056] The third embodiment also provides a coating method for making the novel laser galvanometer lens described in the first embodiment, which includes:

[0057] Using vacuum evaporation coating technology (as a further technical solution, using vacuum evaporation coating technology, and using ion source for deposition assistance throughout the coating process), the first connection film is deposited on the base film layer 1 by electron beam evaporation Layer 2, on the first connection film layer 2, deposit an Al film 3 by resistance heating evaporation, on the Al film 3, deposit a second connection film layer 4 by electron beam evaporation, and on the second connection film layer 4 use The high reflection film layer 5 is deposited by electron beam evaporation.

[0058] The specific structure of the new laser galvanometer lens has been described in detail in the first embodiment above, and will not be repeated here.

[0059] For this embodiment, it can be produced by follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com