Electrochromic device, manufacturing method thereof and color-changing glass

A technology of electrochromic devices and manufacturing methods, which is applied in the fields of instruments, nonlinear optics, optics, etc., and can solve problems such as poor flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

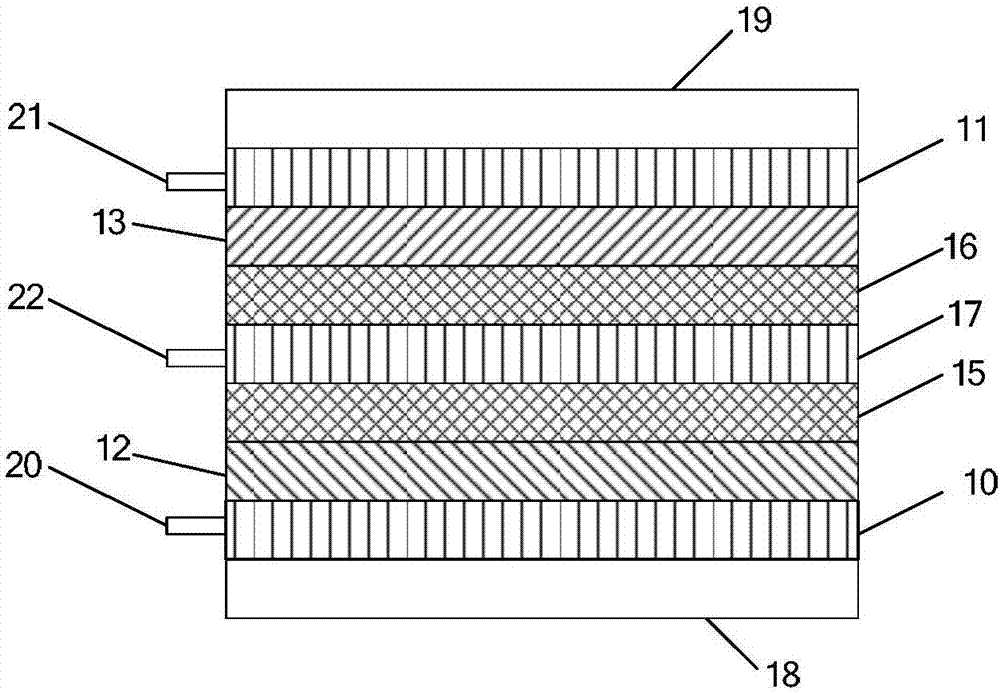

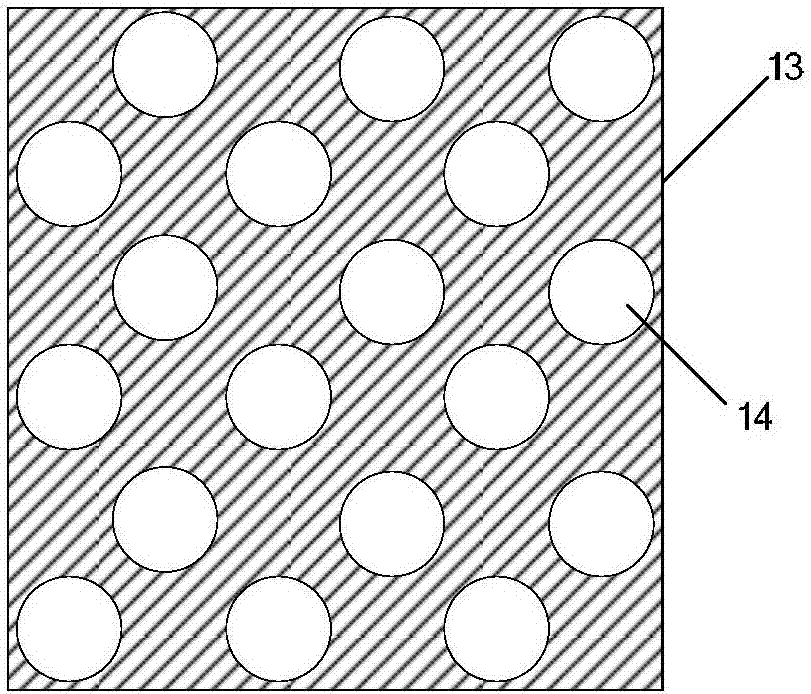

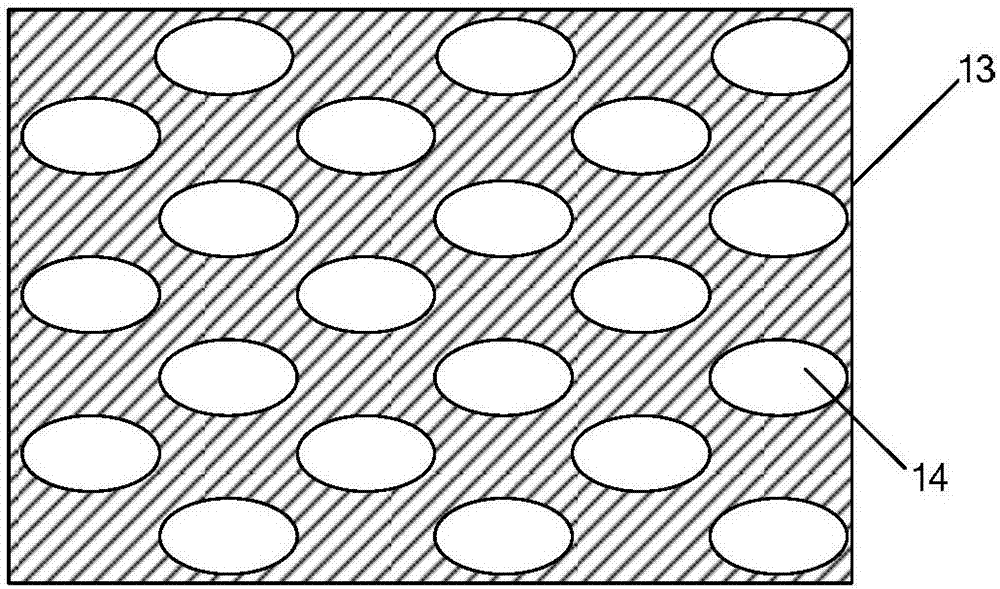

[0029] According to an embodiment of the present invention, an embodiment of an electrochromic device is provided. figure 1 is an electrochromic device according to an embodiment of the present invention, such as figure 1 As shown, the electrochromic device includes: a first electrode layer 10 and a second electrode layer 11 oppositely arranged; a first color-changing thin film layer 12 arranged inside the first electrode layer 10; The second color-changing film layer 13, wherein, at least one hollow geometric structure 14 is formed in the second color-changing film layer 13, and transparent material is filled in the hollow geometric structure 14; 15 , the second ion coupling layer 16 disposed inside the second color-changing thin film layer 13 ; and the third electrode layer 17 disposed between the first ion coupling layer 15 and the second ion coupling layer 16 .

[0030] Wherein, the polarity of the first color-changing film layer 12 and the second color-changing film laye...

Embodiment 2

[0053] According to an embodiment of the present invention, an embodiment of a method for manufacturing an electrotropic thin film device is provided. Figure 6 It is the fabrication method of the electrotropic thin film device according to the embodiment of the present invention, such as Figure 6 As shown, the fabrication method of the electrochromic device comprises the following steps:

[0054] Step S102, forming a third electrode layer on the substrate.

[0055] In the above step S102 of the present application, the third electrode layer is formed by sputtering deposition on the substrate. The substrate may be a glass substrate.

[0056] Step S104, forming a first ion coupling layer on the third electrode layer.

[0057] In the above step S104 of the present application, the first ion coupling layer is formed on the third electrode layer by a sol-gel method.

[0058] Step S106, forming a first color-changing thin film layer on the first ionizing coupling layer.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com