Wrapping method of winding rotor coil

A winding rotor and coating technology, which is applied in the field of coating of wound rotor coils, can solve the problem that Class F insulation cannot meet the requirements of actual use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

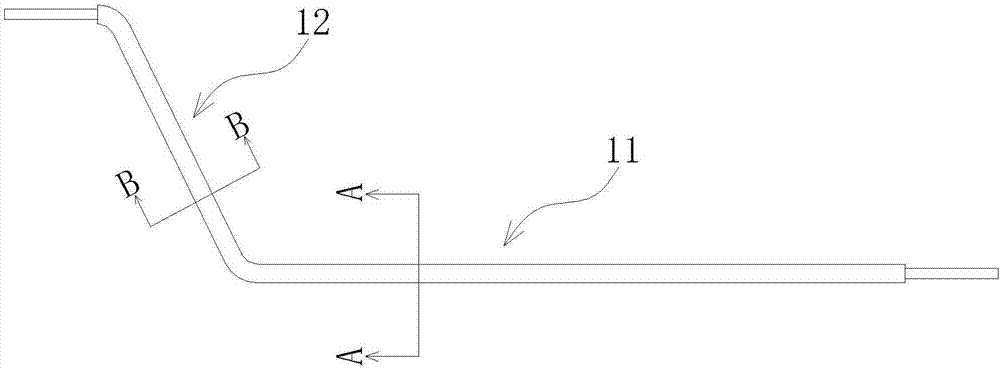

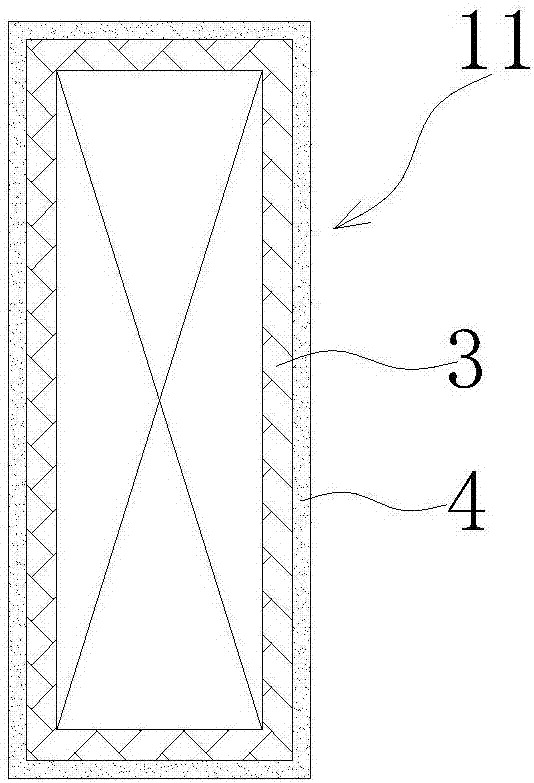

[0013] Embodiment 1: the step S includes the following steps: B, first coat the polyimide film tape 5 on the outer section 12 of the groove, and then coat the organic silicon powder mica tape 3 on the section 11 between the grooves; C, between the grooves After the segment 11 is coated with the silicone powder mica tape 3 , continue to coat the silicone powder mica tape 3 to the outer section 12 of the tank without interruption, covering the polyimide film tape 5 .

Embodiment approach 2

[0014] Embodiment 2: the step S includes the following steps: B1, first coat the silicone powder mica tape 3 on the inter-slot section 11, and place the two ends of the silicone powder mica tape 3 freely after coating; C1, Coat the polyimide film tape 5 on the outer section 12 of the tank, and then continue to coat the two ends of the silicone powder mica tape 3 in step B1 to cover the polyimide film tape 5 on the inter-slot section 11 .

Embodiment approach 3

[0015] Embodiment 3: the step S includes the following steps: B2, first coating the polyimide film tape 5 on the outer section 12 of the tank; C2, coating the silicone powder mica tape 3 from the outer end of the outer section 12 of the tank , the inter-slot section 11 and the slot-outside section 12 of the flat copper coil 10 are continuously and completely covered.

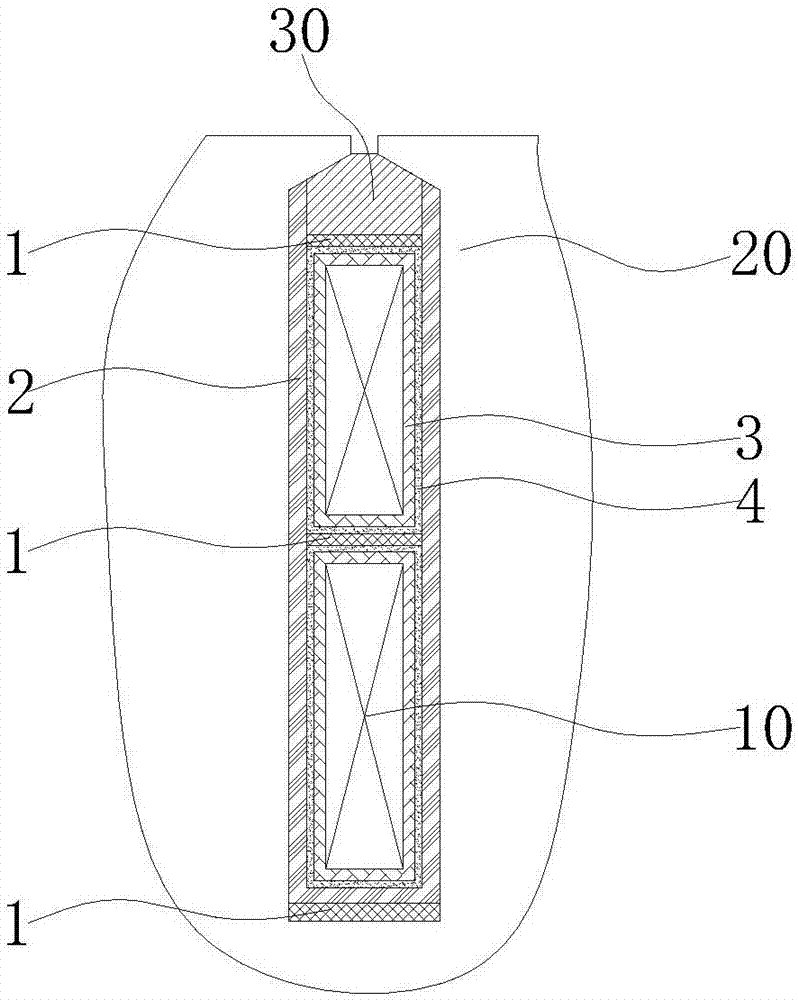

[0016] The following steps are also included: E, an epoxy phenolic glass cloth plate 1 is arranged at the bottom of the rotor slot 20 in advance, and a polyesterimide film polyaramid fiber paper composite material 2 is arranged on the inner wall of the rotor slot 20; F, the The inter-slot section 11 of the flat copper coil 10 is inserted into the rotor slot 20, the slot outer section 12 of the flat copper coil 10 protrudes from the rotor slot 20 and is turned outward, and the slot wedge 30 is inserted into the notch of the rotor slot 20; G, adjacent An epoxy phenolic glass cloth plate 1 is arranged between the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com