Rotary efficient bag-type dust collector

A bag filter and rotary technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of reducing the service life of filter bags, uneven air distribution, reducing dust removal efficiency, etc., to increase the use of Longevity, good removal of dioxins, and enhanced dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

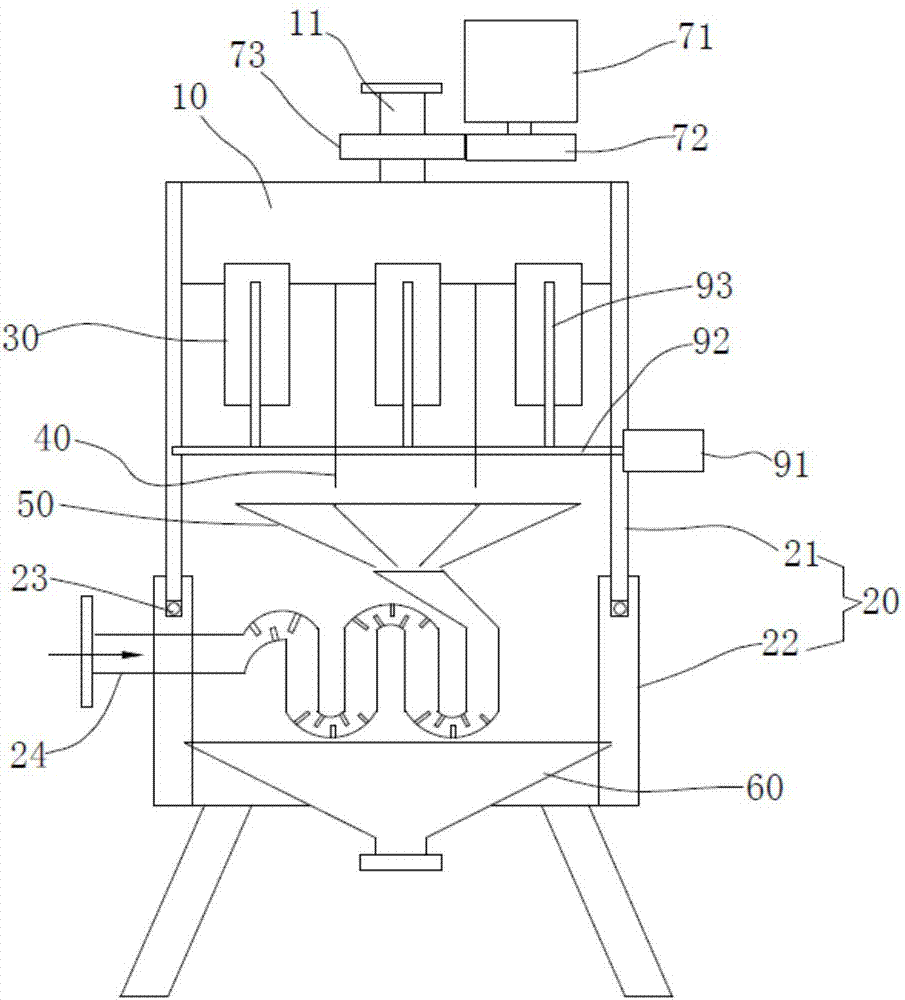

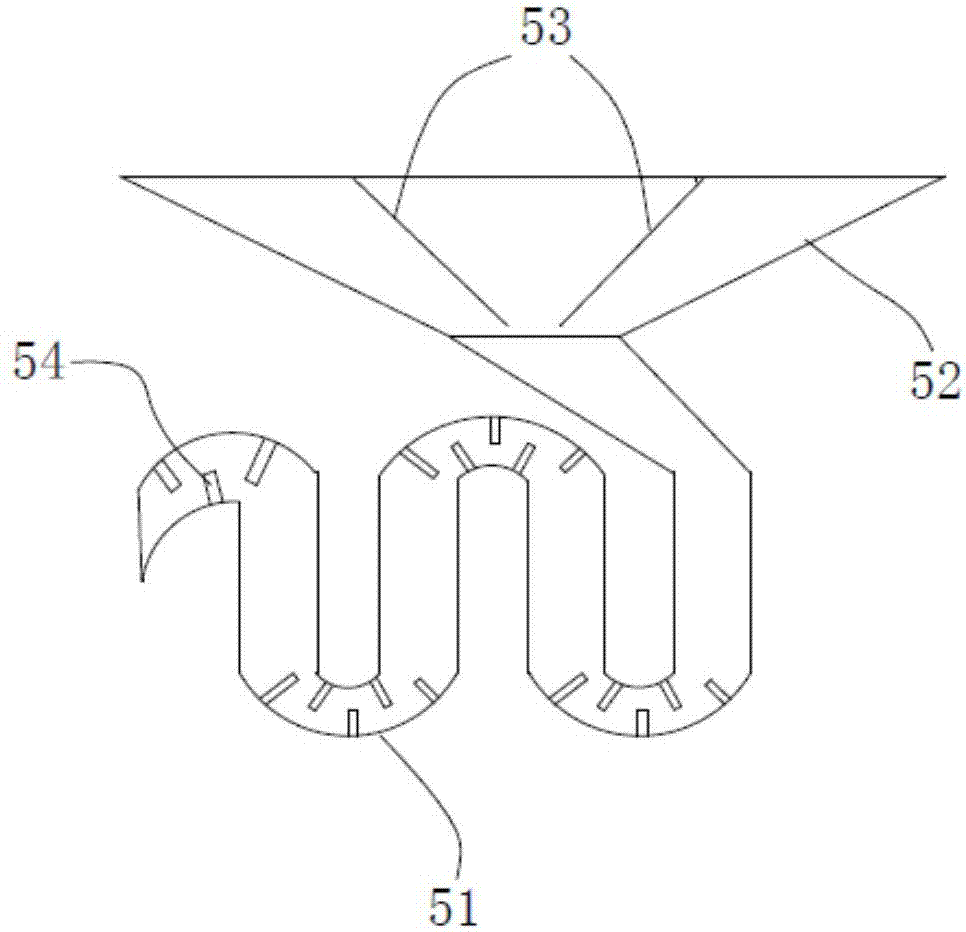

[0024] Such as Figure 1-3 As shown, a rotary high-efficiency bag filter includes an air outlet box 10, a dust box 20 and a dust bag 30; The top opening edge of the lower housing 22 is provided with an annular groove, the bottom of the upper housing 21 is arranged in the annular groove, and a ball 23 is arranged in the annular groove; the gas outlet box 10 is arranged in the upper housing The top of the top of the air outlet box 10 is provided with an air outlet pipe 11 at the center; one end of the dust bag 30 is located in the upper housing 10, and the other end of the dust bag 30 is located in the air outlet box 20; the side of the lower housing 22 The wall is provided with an air inlet pipe 24, and the air outlet end of the air inlet pipe 24 is provided with a flow diverter device 50, and the air outlet end of the air flow device 50 is facing the dust bag 30; There is a stepper motor 91, and a shaking rod 93 perpendicular to the rotating shaft is arranged on the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com