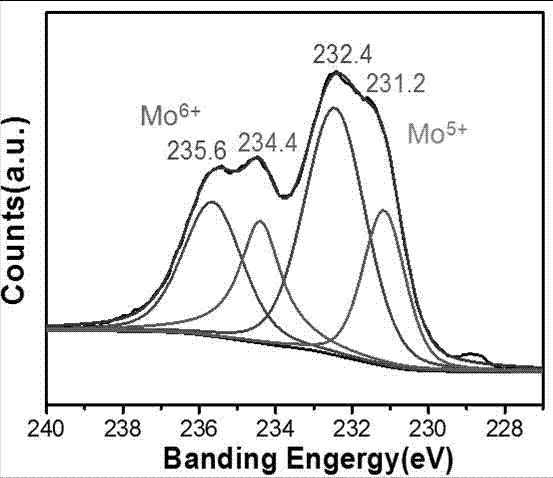

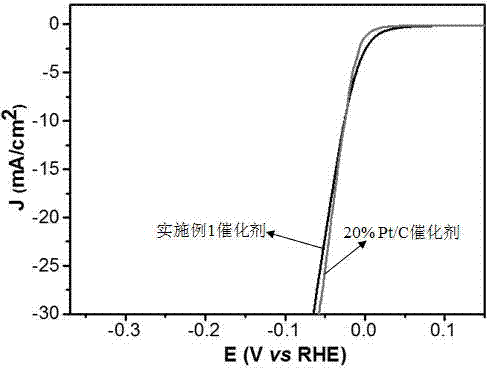

Preparation method of molybdenum-oxide-based efficient catalyst for electrocatalytic hydrogen evolution

A technology of molybdenum oxide and electrocatalysis, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of low platinum utilization efficiency and improve the utilization rate , high catalytic activity, and the preparation technology is environmentally friendly and pollution-free

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

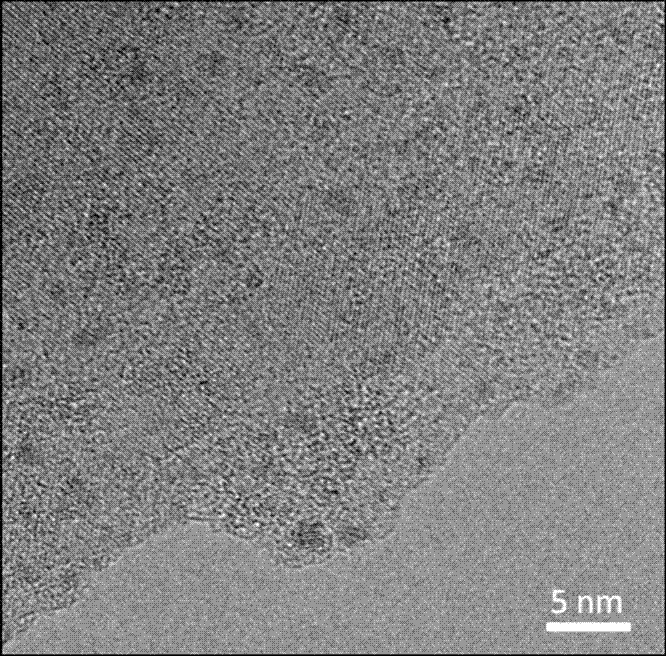

Embodiment 1

[0017] A method for preparing a molybdenum oxide-based high-efficiency electrocatalytic hydrogen evolution catalyst, the steps are as follows:

[0018] (1) Prepare substoichiometric molybdenum oxide according to the method of Example 1 in CN201611140260.4, the specific process is:

[0019] Fill the beaker with 10ml of 45% (volume ratio, the same below) ethanol, disperse 100mg of molybdenum sulfide in 10ml of 45% ethanol, then ultrasonicate the beaker containing the solution in a water bath for 4 hours, dry it in an oven, and then place it in a carbonization furnace at 350°C Calcined in the air environment for 90 minutes, the heating rate is 10 ℃ per minute; the calcined product is redispersed in 45% ethanol, and then ultrasonicated for 1 hour to disperse evenly, then transferred to the reactor, and carbon dioxide is injected into the reactor to make it supercritical State (16Mpa, 80°C), react for 3h under magnetic stirring; transfer the sample after supercritical treatment to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com