Hand cranking type linear guide rail taper head

A linear guide rail, hand-operated technology, applied in the direction of electric processing equipment, metal processing equipment, electrode manufacturing, etc., can solve the problems that the cutting range cannot meet the processing needs of the market, affect the processing efficiency, and the transmission accuracy is low, so as to facilitate the adjustment of the taper And the effect of correcting the verticality of molybdenum wire, improving processing efficiency and improving transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

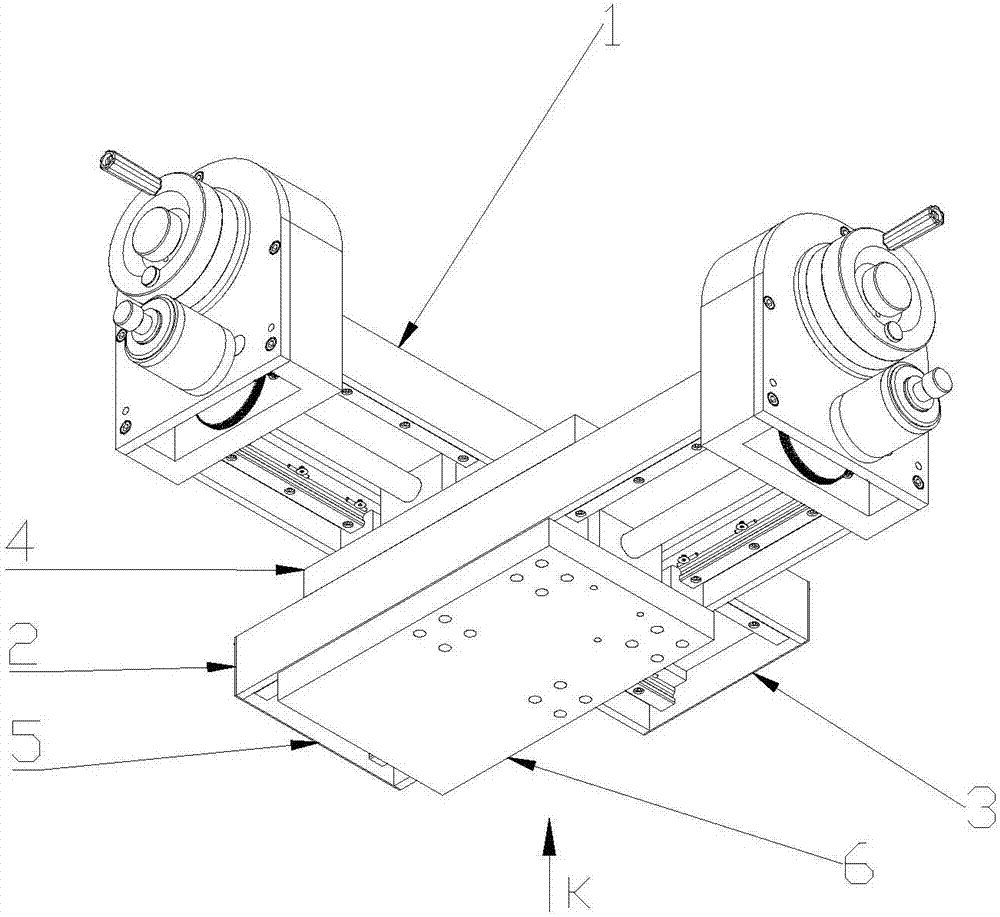

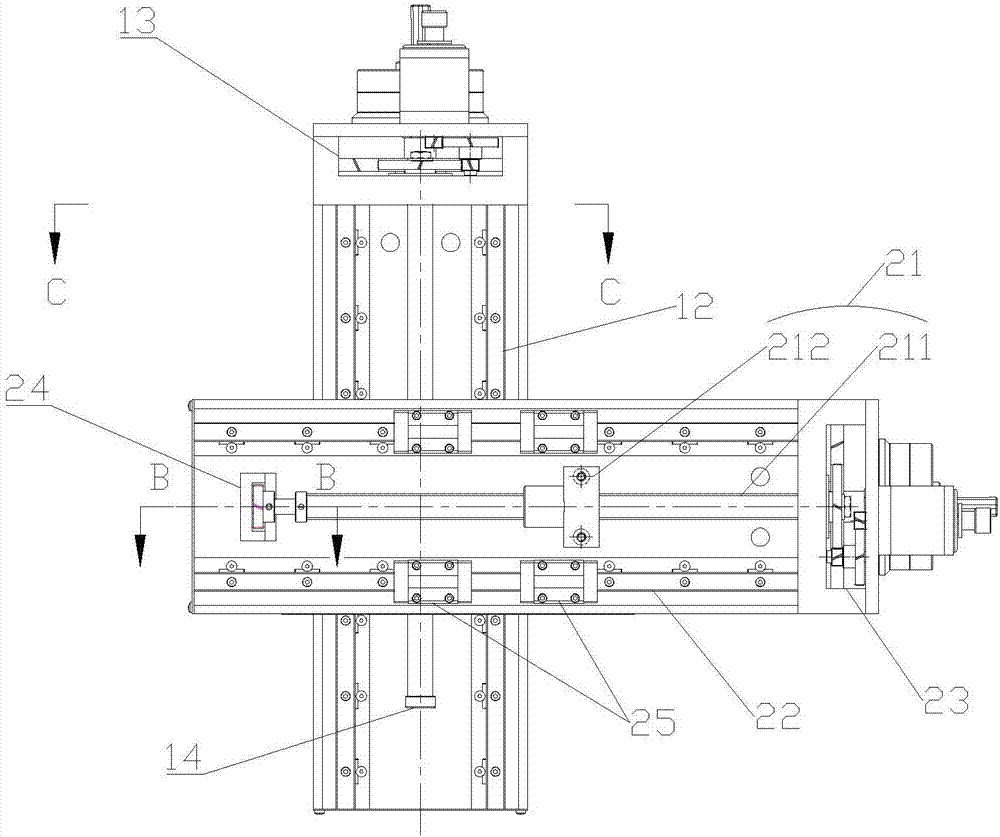

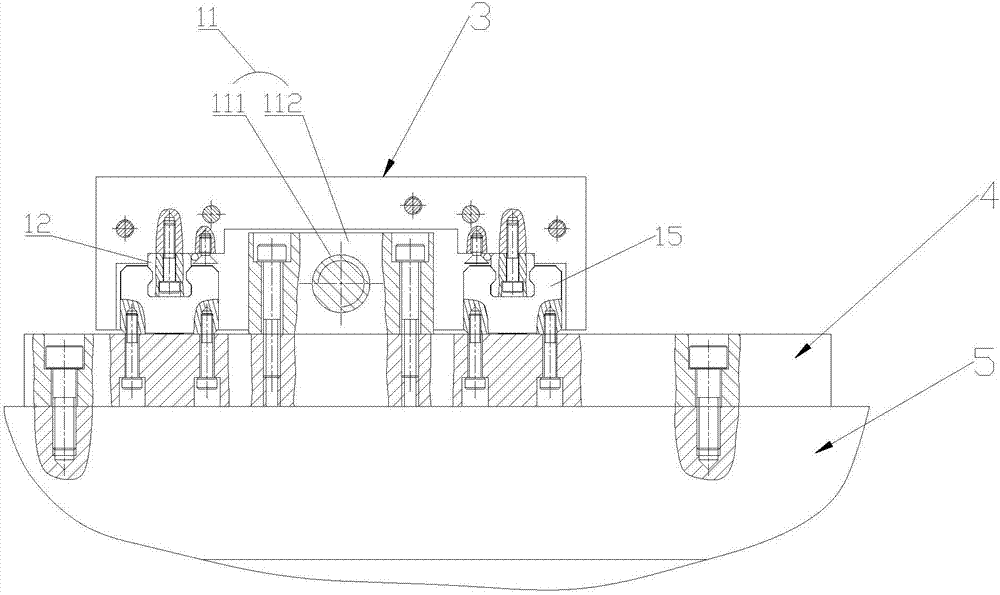

[0017] like Figure 1-2 Shown is a hand-cranked linear guide taper head, including U-axis 1, V-axis 2, upper support plate 3, upper transition plate 4, lower support plate 5 and lower transition plate 6, U axis 1 and upper support plate 3 Fixed connection, U-axis 1 includes ball screw a11, linear guide a12, gear box a13, limit sleeve 14, linear guide a12 is fixed in parallel on both sides of the bottom end of upper pallet 3, ball screw a11 includes screw a111 and Nut a112, one end of the screw a111 is set in the limit sleeve 14, the limit sleeve 14 is fixed on the bottom of the upper support plate 3, the other end is mechanically connected with the gear box a13, the nut a112 is fixed on the upper transition plate 4, on the upper transition plate 4 The end face is also fixed with at least a pair of sliders a15, the sliders a15 slide in the linear guide rail a12, the lower end surface of the upper transition plate 3 is fixedly connected with the upper end surface of the lower su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com