3D printer using thermoplastic polymer materials

A thermoplastic polymer, 3D printer technology, used in 3D object support structures, additive processing, coating devices, etc., can solve the problem of scarcity of printable consumables, and achieve the effect of accurate accumulation and expansion of types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. All other embodiments obtained by persons of ordinary skill in the art based on the embodiments of the present invention belong to the protection scope of the present invention.

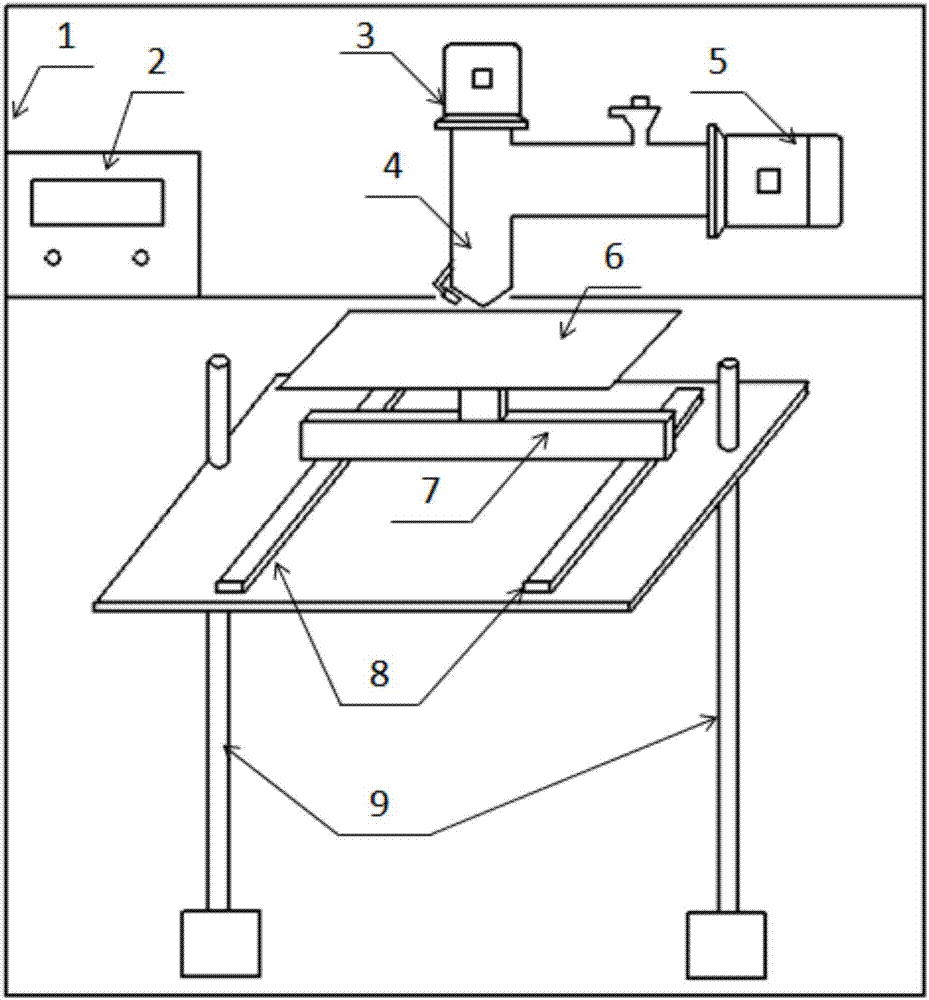

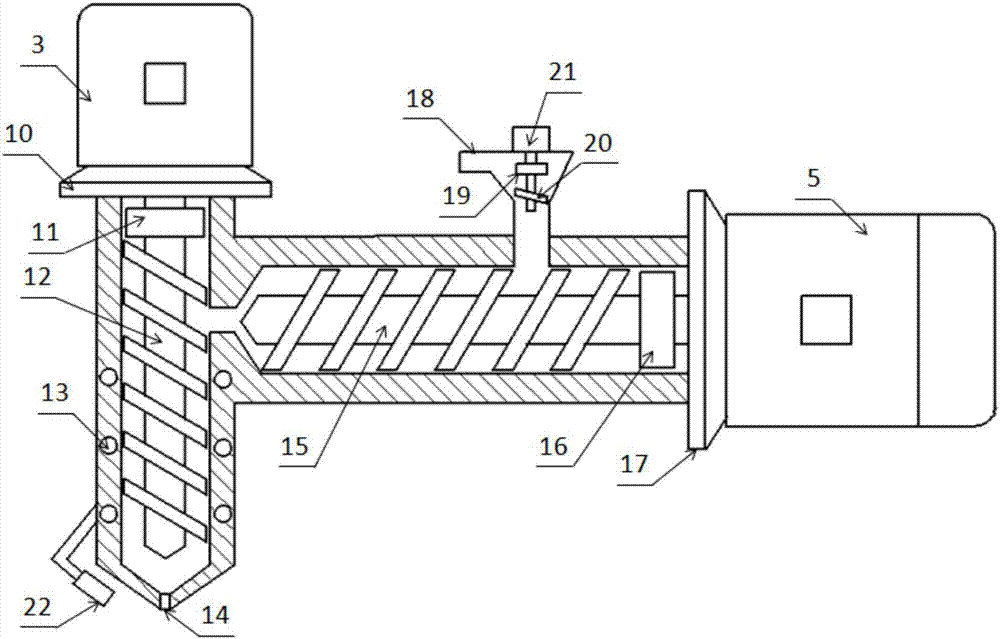

[0020] like Figure 1-2 As shown, a 3D printer using thermoplastic polymer materials according to an embodiment of the present invention includes a frame 1 on which a control system 2 and a printer head are arranged, and the printer head includes a barrel 4 One end of the barrel 4 is provided with a feeding port 18, and the other end of the barrel 4 is provided with a nozzle 14, and the barrel 4 is sequentially arranged from the feeding port 18 to the nozzle 14 The...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap