Back-contact solar cell double-glass assembly and manufacturing method thereof

A technology of solar cells and back-contact cells, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problem of difficult double-glass technology packaging, and achieve the effects of low material cost, easy industrialization, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

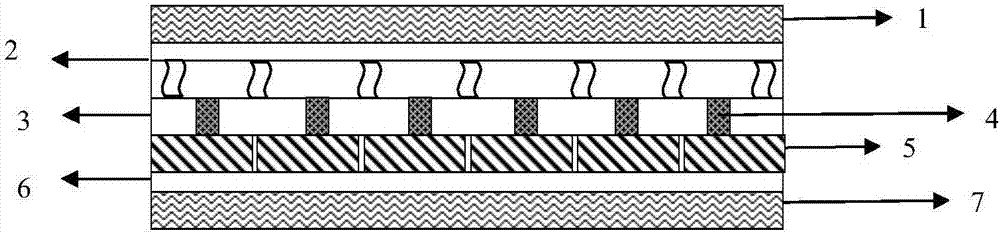

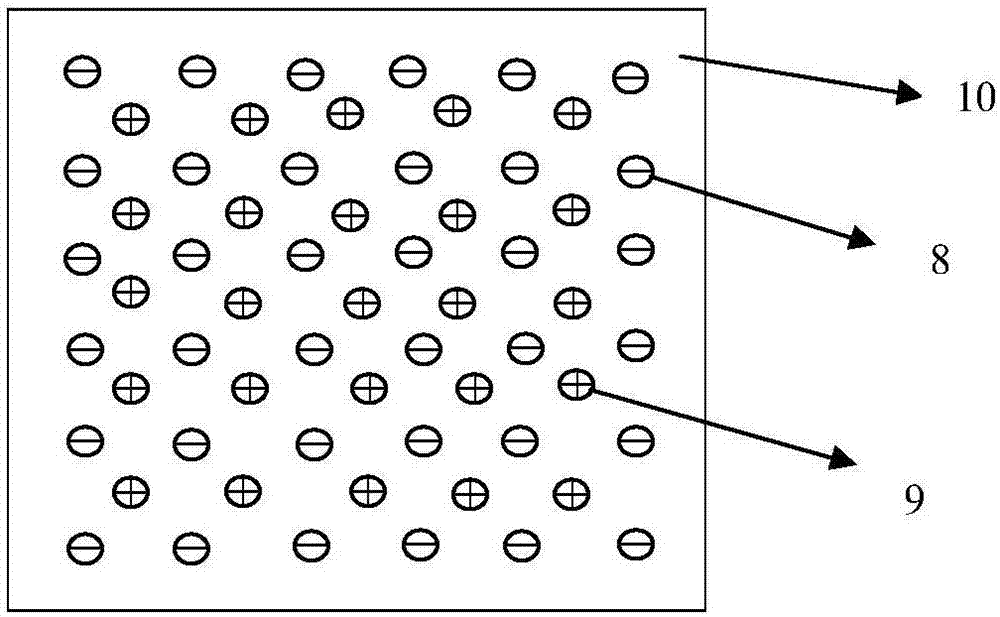

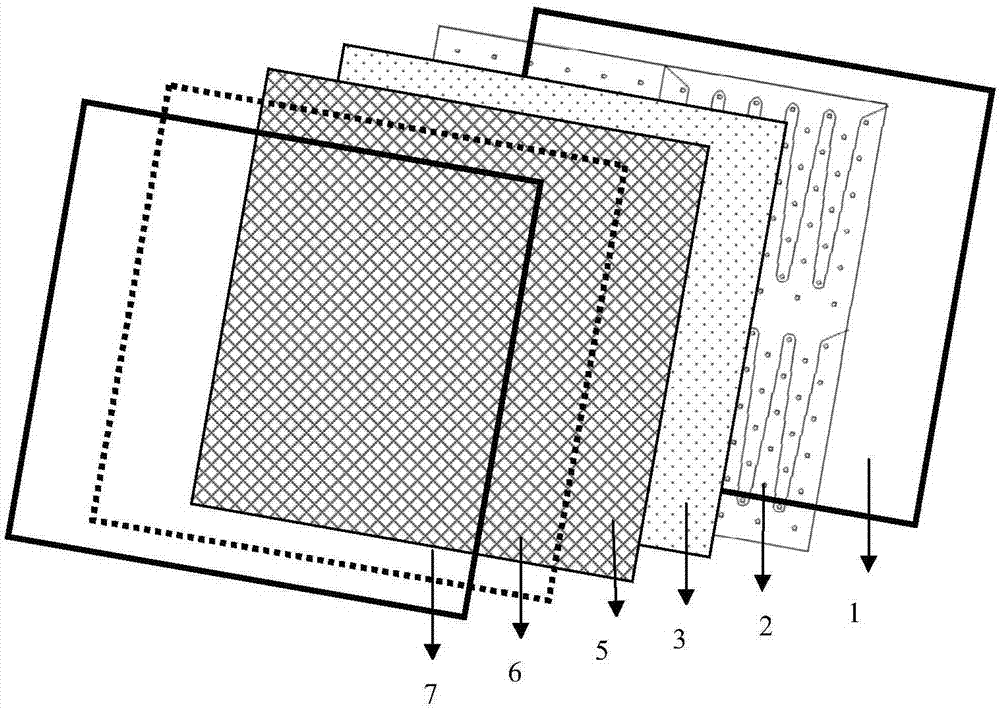

[0033] Back-contact solar cells The double-glass solar cell array consists of seven layers, specifically including the first glass layer 1, the metal conductive circuit core layer 2, the sealing insulation isolation material layer 3, and the conductive medium connection point layer stacked together from bottom to top. 4. The back contact cell layer 5 , the encapsulation material layer 6 and the second glass layer 7 . Several MWT back contact cells 10 such as figure 2 As shown, positive electrodes 9 and negative electrodes 8 are discretely distributed on the back of the battery sheet 10 . In the assembly production of such a back contact cell, the positive electrode 9 and the negative electrode 8 are connected with a conductor and packaged.

[0034] The core board layer 2 of the metal conductive circuit includes a bottom adhesive film and an upper metal circuit, and the metal circuit is adhered to the bottom adhesive film; the metal circuit is provided with conductive medium ...

Embodiment 2

[0042] Select a conductive copper core plate as the core plate of the conductive circuit, print or deposit the connection point of the conductive medium on the metal circuit, the position of the connection point of the conductive medium is the same as the positive and negative electrode points (9,8) on the back of the back contact solar cell Corresponding; lay a layer of sealing insulation isolation material layer 3 with several through holes on it, the number of through holes is consistent with the sum of the number of positive and negative electrodes of several batteries, and the position of the through holes needs to correspond to the positive and negative electrodes of the pre-arranged batteries Position, the hole diameter is 2mm, and the position of the through hole needs to correspond to the position of the conductive glue point (dielectric connection point) of the conductive core board when placing the sealing insulation isolation material layer 3 at the same time, so tha...

Embodiment 3

[0044] Prepare a piece of flat glass with a thickness of 2mm as the first glass layer 1, lay a metal conductive circuit core layer 2 on it, place it in the center, and then print or deposit a conductive medium connection point on the metal conductive circuit, and the conductive medium connection point is in contact with the back The positive and negative electrode points (9,8) on the back of the type solar cell correspond to each other; then place a sealing insulation isolation material layer 3 with a number of through holes on it, and the positions of the through holes need to correspond to the positive and negative electrode positions of the pre-arranged batteries , the hole diameter is 2.5mm, and when placing the sealing insulation isolation material layer 3 at the same time, the position of the through hole needs to correspond to the position of the conductive glue point (conductive medium connection point) one by one, so that the conductive medium connection point passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com