Tail-gas treating process in preparation process of calcined clay

A technology for preparation process and exhaust gas treatment, which is applied in the direction of using liquid separation agent, dispersed particle separation, chemical instruments and methods, etc., to achieve the effect of saving treatment cost, simple process and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

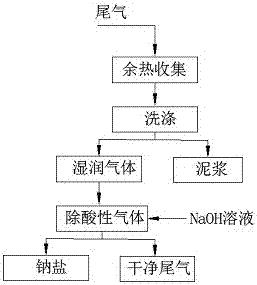

[0017] Such as figure 1 As shown, a tail gas treatment process in the preparation process of calcined clay includes the washing of traditional tail gas treatment methods and the removal of acid gas. The steps are as follows:

[0018] Step 1: Collect waste heat from the tail gas to cool the tail gas.

[0019] Step 2: Pass the tail gas into the water tank to wash the tail gas, the dust and solid particles in the tail gas are precipitated to obtain mud, and the remaining tail gas becomes wet gas.

[0020] Step 3: Pass the wet gas of the tail gas into the NaOH solution, the concentration of the NaOH solution is 8%, and the SO in the tail gas 2 , SO 3 , CO 2 React with NaOH to get sodium salt and clean tail gas.

example 2

[0022] Such as figure 1 As shown, a tail gas treatment process in the preparation process of calcined clay includes the washing of traditional tail gas treatment methods and the removal of acid gas. The steps are as follows:

[0023] Step 1: Collect waste heat from the tail gas to cool the tail gas;

[0024] Step 2: Pass the tail gas into the pool to wash the tail gas, the dust and solid particles in the tail gas are precipitated to obtain mud, and the remaining tail gas becomes wet gas;

[0025] Step 3: Pass the tail gas wet gas into the NaOH solution, the concentration of the NaOH solution is 10%, the SO in the tail gas 2 , SO 3 , CO 2 React with NaOH to get sodium salt and clean tail gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com