Polishing treatment device

A technology of processing device and polishing device, which is applied to grinding drive device, grinding/polishing equipment, device for fixing grinding wheel, etc., can solve the problems of low work efficiency, frequent equipment replacement, time-consuming and labor-consuming, etc. Inexpensive, better polished results for a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

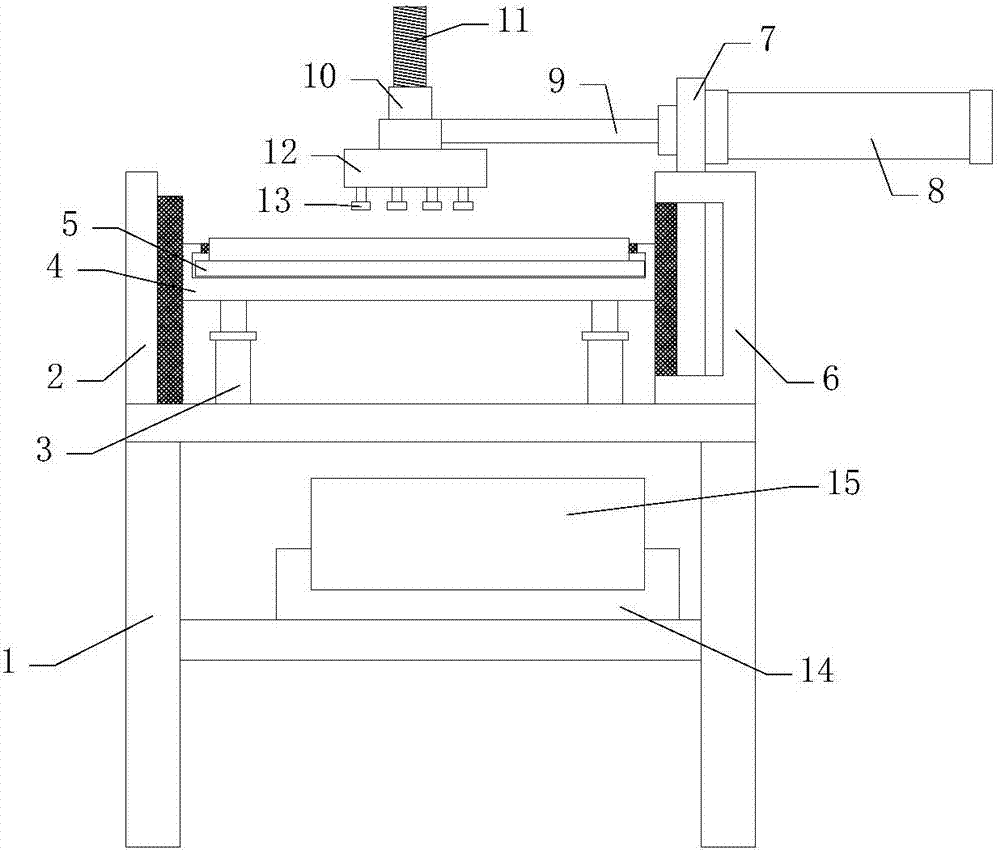

[0023] Such as figure 1 Shown, a kind of polishing treatment device comprises support 1, motor 15, fixed seat 4 and polishing device, described support 1 is provided with motor 15, and described fixed seat 4 is installed on support 1 top, and described fixed One end of the seat 4 is provided with a baffle 2, and the other end of the fixed seat 4 is provided with a support seat 6;

[0024] The polishing device includes a polisher 13, a fixed disc 12, a lifting rod 11 and a telescopic rod. A sleeve 10 is arranged above the fixed disc 12, and a lifting rod 11 is arranged inside the sleeve 10. The described The polisher 13 is installed under the fixed plate 12, and a telescopic rod is provided on the upper side of the story;

[0025] Described motor 15 links to each other with elevating rod 11 and telescoping rod.

[0026] Described telescoping link comprises slide bar 9, slide sleeve 8 and fixed plate 7, and described slide bar 9 one end is fixed on the fixed plate 12, and desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com