Apple-flavor essence for cigarettes and preparation method of essence

A technology for cigarette flavor and apple flavor, applied in the field of apple flavor cigarette flavor and preparation thereof, can solve the problems of insufficient aftertaste, poor roundness, rough and dry apple flavor, etc., and achieve the effect of soft and delicate aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

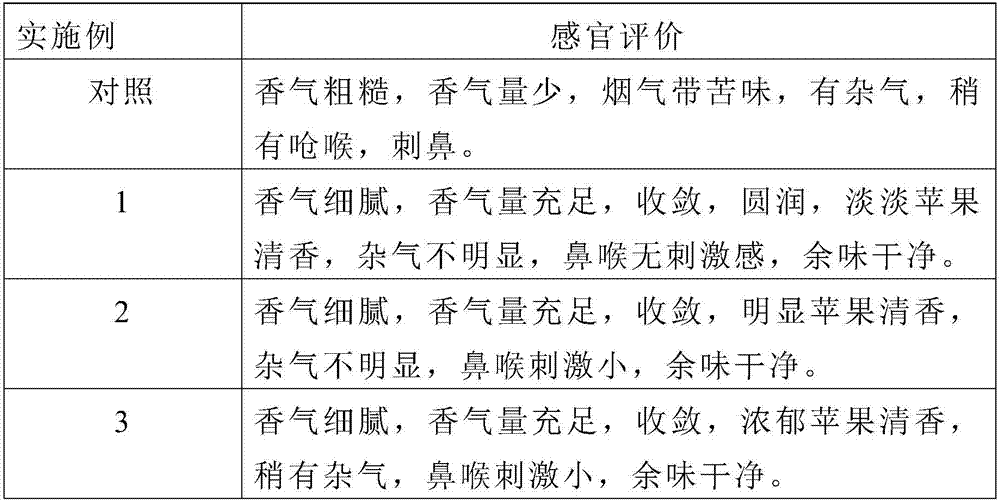

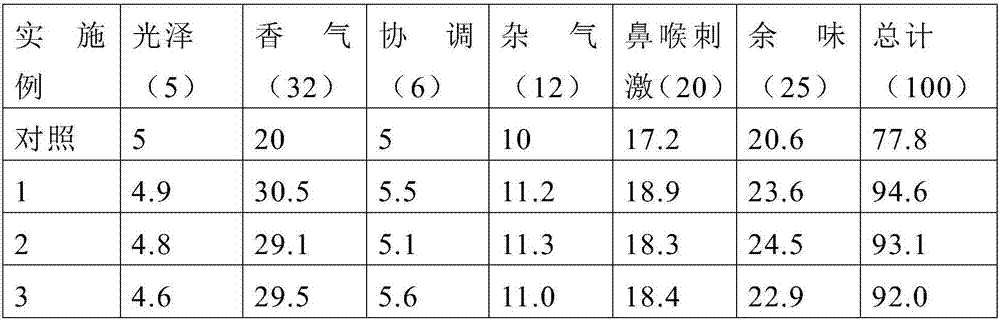

Examples

Embodiment 1

[0021] The preparation method of apple-flavored essence for tobacco comprises the following steps:

[0022] 1) Preparation of apple juice extract:

[0023] The apples are inspected, washed, and crushed; then the broken apples are beaten to make apple puree, and the apple puree and water are mixed evenly at a weight ratio of 1:4 to obtain apple water; then add 0.005% of its weight to the apple water Sodium chloride, sterilizing 15min makes apple culture medium, adds compound bacteria preparation in apple culture medium and ferments, and described compound bacteria preparation is aspergillus oryzae, brewer's yeast, and lactic acid bacteria is 1:2:2 by weight; The input amount of the compound bacteria preparation is 0.1% of the weight of the apple culture medium to obtain a fermented liquid; the fermented liquid is centrifuged at 4000rpm to obtain a supernatant to obtain an apple juice extract; the pH of the fermentation is 6.5, the rotating speed is 50rpm, and the ventilation ra...

Embodiment 2

[0027] 1) Preparation of apple juice extract:

[0028] The apples are inspected, washed, and crushed; then the broken apples are beaten to make apple puree, and the apple puree and water are mixed uniformly at a weight ratio of 1:4 to obtain apple water; then add 0.02% of its weight to the apple water Sodium chloride, sterilizing 30min makes apple culture medium, adds compound bacteria preparation to ferment in apple culture medium, and described compound bacteria preparation is aspergillus oryzae, brewer's yeast, and lactic acid bacteria is 1:4:4 by weight; The input amount of the compound bacteria preparation is 0.3% of the weight of the apple culture medium to obtain a fermented liquid; the fermented liquid is centrifuged at 4000rpm to obtain a supernatant to obtain an apple juice extract; the pH of the fermentation is 7.5, the rotating speed is 100rpm, and the ventilation rate 0.5VVM, the fermentation temperature is 30°C, and the fermentation is for 7 days.

[0029] 2) De...

Embodiment 3

[0032] 1) Preparation of apple juice extract:

[0033] The apples are inspected, washed, and crushed; then the broken apples are beaten to make apple puree, and the apple puree and water are mixed evenly at a weight ratio of 1:4 to obtain apple water; then add 0.01% of its weight to the apple water Sodium chloride, sterilizing 25min makes apple culture medium, adds composite bacteria preparation in apple culture medium and ferments, and described composite bacteria preparation is aspergillus oryzae, brewer's yeast, and lactic acid bacteria is 1:3:3 by weight; The input amount of the compound bacteria preparation is 0.2% of the weight of the apple culture medium to obtain a fermented liquid; the fermented liquid is centrifuged at 4000rpm to obtain a supernatant to obtain an apple juice extract; the pH of the fermentation is 7.0, the rotating speed is 80rpm, and the ventilation rate 0.3VVM, the fermentation temperature was 28°C, and the fermentation was carried out for 6 days. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com