High-pressure cooling stage device for in-situ observation of particle size distribution of gas hydrate and application method

A gas hydrate and particle size distribution technology, which is applied in the fields of measuring device, particle size analysis, particle and sedimentation analysis, etc. It can solve the problems of inability to simulate the high-pressure reaction process of hydrate and high cost, achieve compact structure, reduce impact, and improve continuous The effect of sex and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

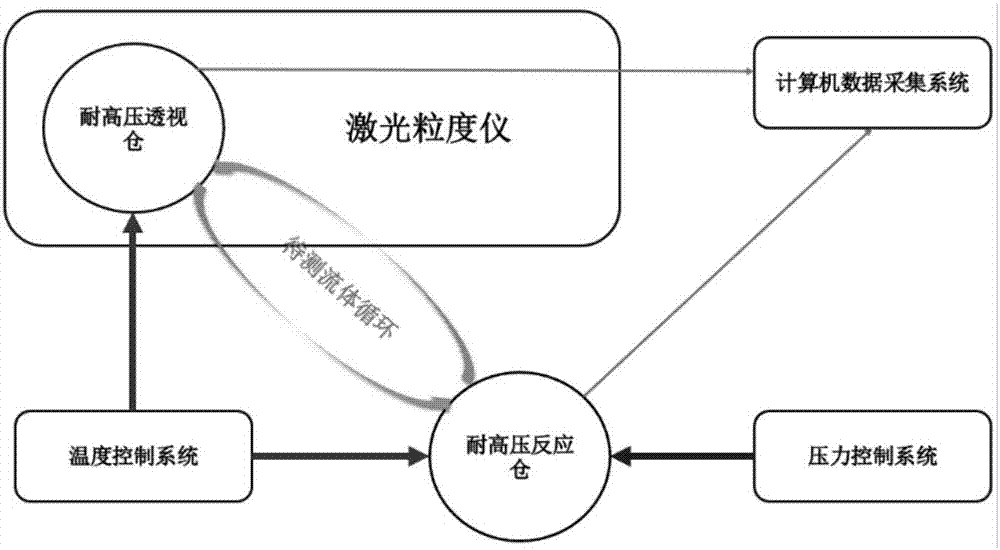

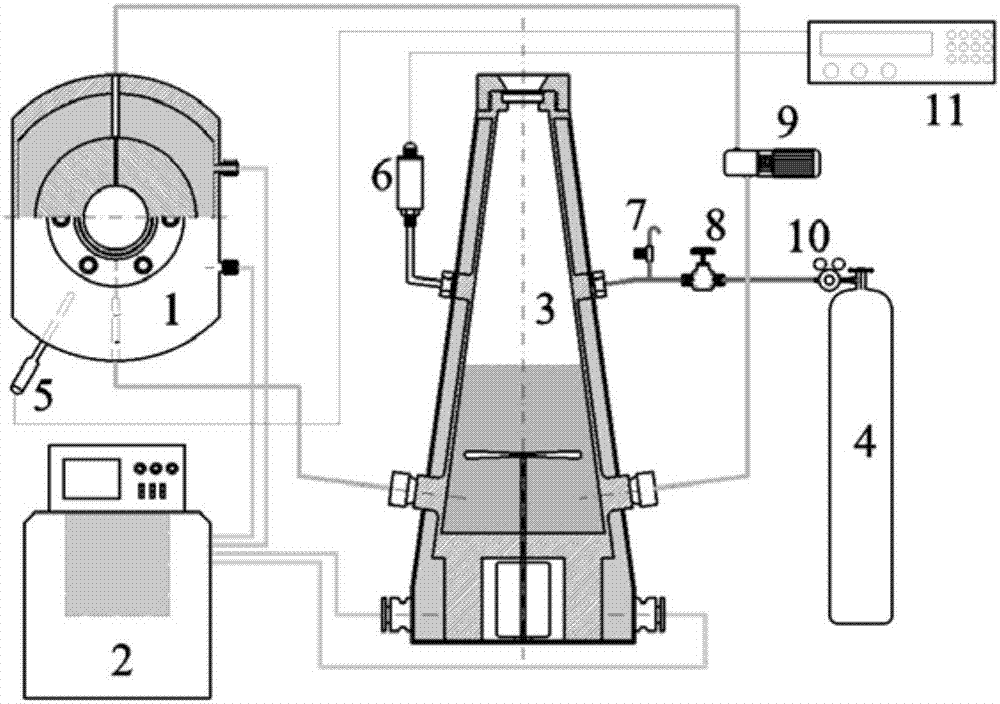

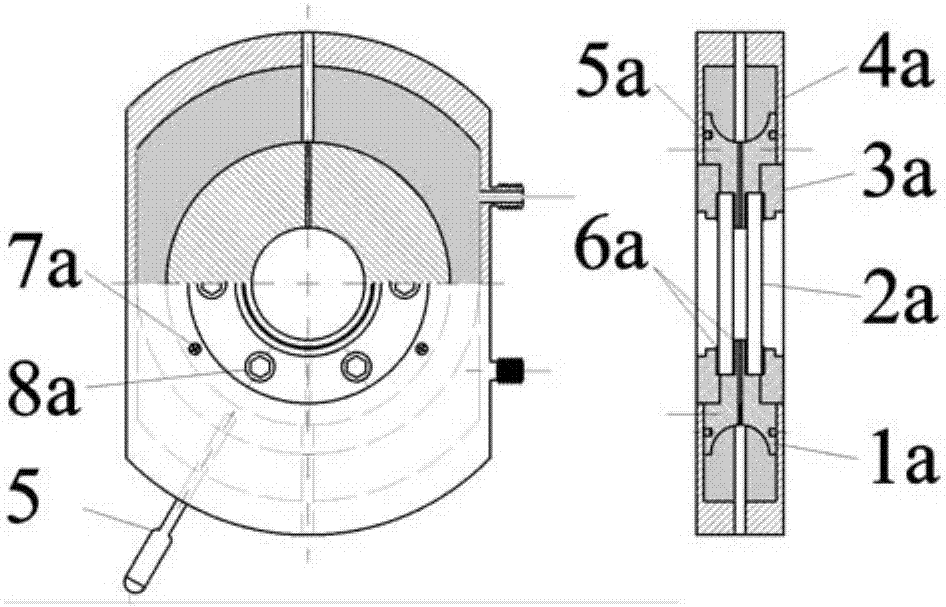

[0032] Such as figure 2 A high-pressure cold table device for in-situ observation of gas hydrate particle size distribution is shown. This device cooperates with a laser particle size analyzer to complete the measurement of the particle size and particle size distribution of gas hydrate crystals in the fluid. The device includes a high-pressure resistant perspective chamber 1 , High-pressure resistant reaction chamber 3. Temperature control system, pressure control system, computer data acquisition system; such as Figure 2-4 As shown, the high-pressure resistant fluoroscopic chamber 1 is a high-pressure resistant container with a sapphire glass window, and the sapphire glass 2a covered with an antireflection film is used as the visible window to provide a sample to be tested for the laser particle size analyzer; the high-pressure resistant fluoroscopic chamber 1 It is fixed on the holder inside the laser particle size analyzer. The holder fixes the high-pressure fluoroscopy bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com