Cooling device for screw granulator

A technology of screw granulator and cooling device, which is applied in the direction of extrusion and granulation of raw materials, can solve the problems of low production efficiency, generate a lot of heat, and the machine cannot work continuously, and achieve low cost, reduced frictional heat, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

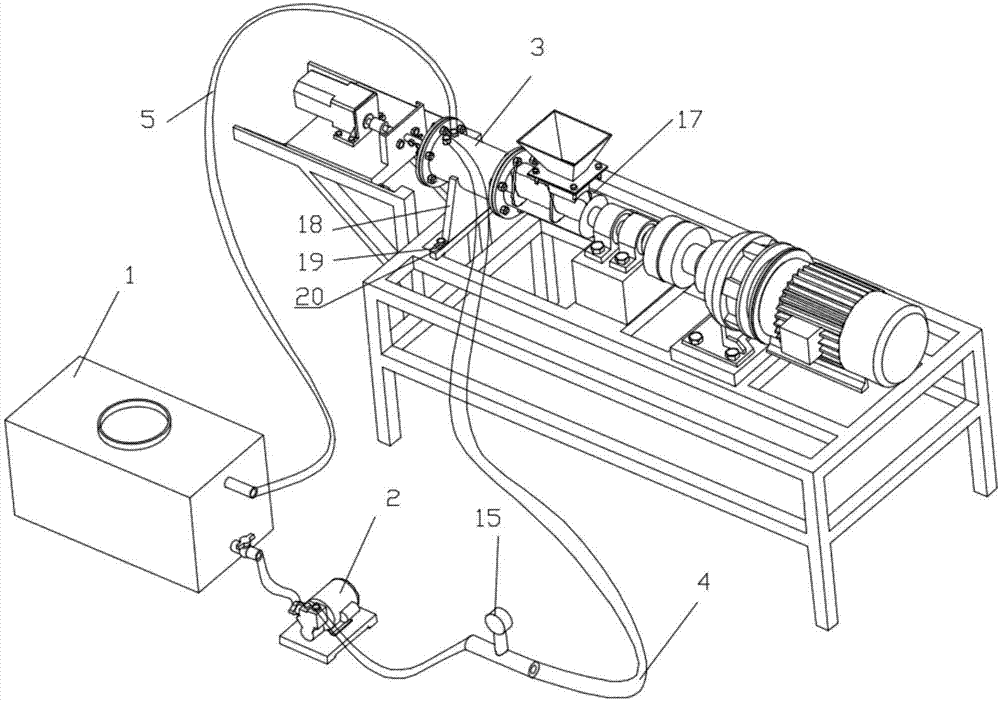

[0022] The structural representation of the cooling device for the screw granulator of the present invention is as figure 1 As shown, the device includes a water tank 1, a cooling water jacket 3, a water inlet pipe 4, a drain pipe 5 and a water jacket support.

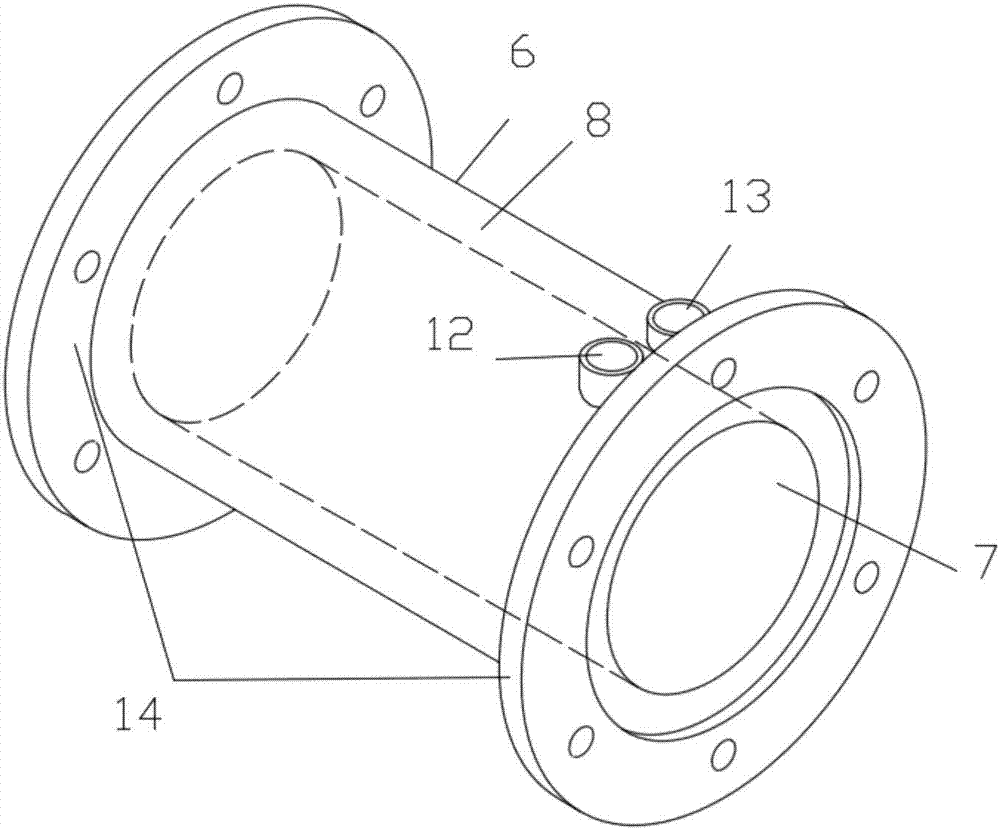

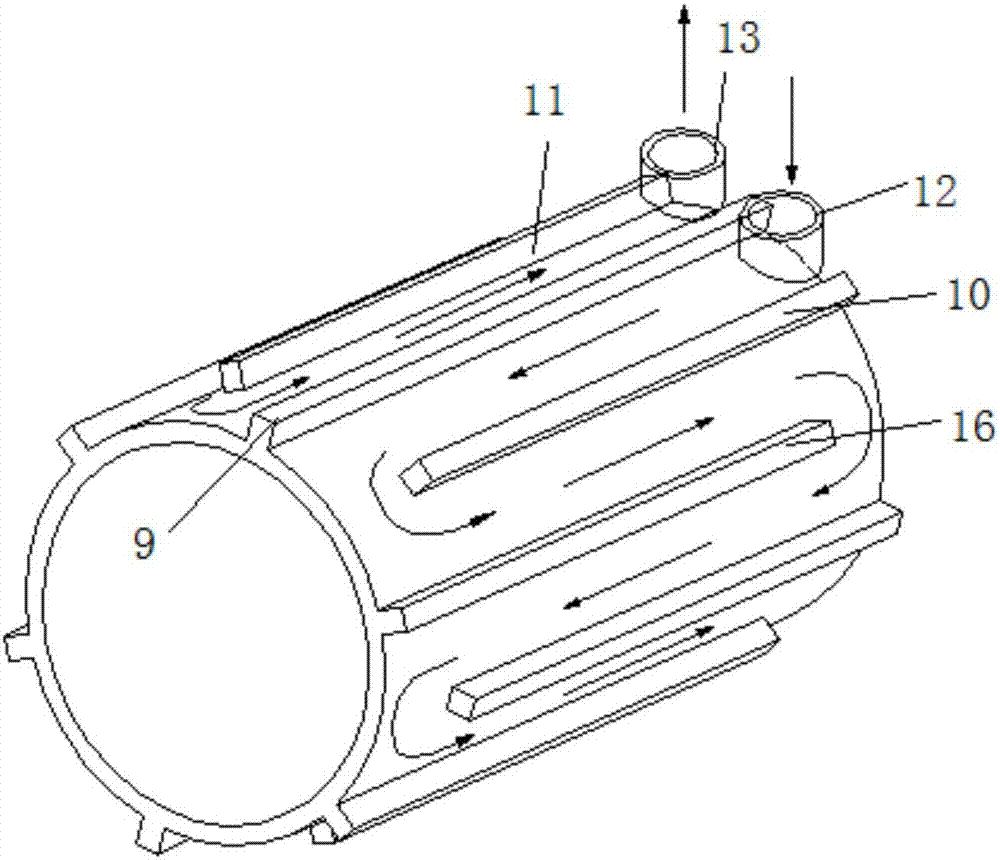

[0023] Both ends of the cooling water jacket 3 are provided with flanges 14, the cooling water jacket 3 includes an outer sleeve 6 and an inner core 7, and one end of the same side of the outer sleeve 6 and the inner core 7 is fixed to one of the flanges On the disc 14, the other end of the outer sleeve 6 and the same side of the inner core tube 7 are fixed on another flange 14, and the inner diameter of the inner core tube 7 is the same as the diameter of the center hole of the flange 14. An airtight annular interlayer 8 is formed between the outer sleeve 6 , the inner core 7 and the two flanges 14 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com