Processing technology of Omega seamless steel pipe

A technology of seamless steel pipe and processing technology, applied in the field of seamless steel pipe processing, can solve the problems of dependence on imports, low efficiency of finished products, high price, etc., and achieve the effect of good straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

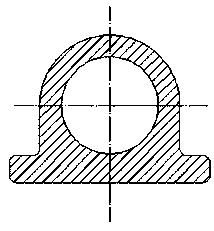

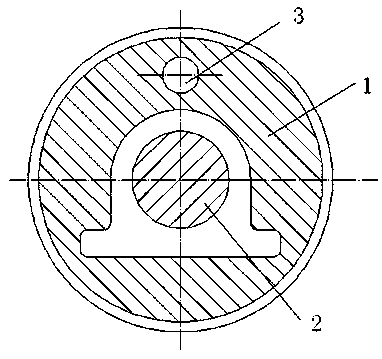

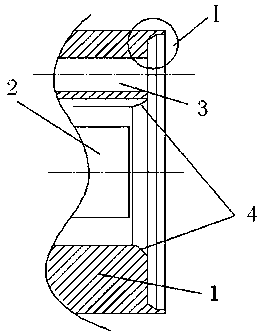

Image

Examples

Embodiment Construction

[0030] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0031] 1. Design and selection of hot extrusion equipment.

[0032] A horizontal hydraulic press with a hydraulic thrust of 2,000 tons is selected and equipped with a hydraulic accumulator to ensure that the working speed is ≥12m / min.

[0033] 2. Selection of billet heating equipment.

[0034] The medium frequency (30KHz) induction heater is selected, and it is equipped with an automatic temperature control device and an automatic material delivery device. The heater has a strong penetrating ability to heat the workpiece, and the temperature difference between the inside and outside of the workpiece is small, and the oxide scale is small. The hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com