Ceramic fiber heat insulation pad and preparation method thereof

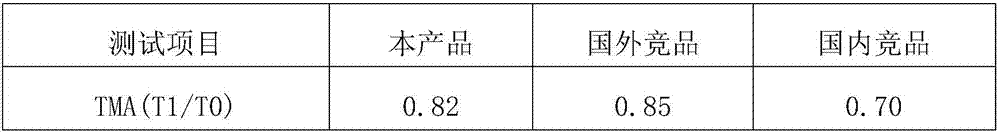

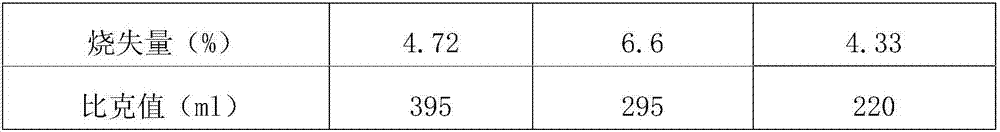

A technology of ceramic fiber and thermal insulation pad, which is applied in the field of ceramic fiber thermal insulation pad and its preparation, can solve the problems of uneven quality and high price of imported products, and achieves good stretching, large price advantage, and good price. The effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of ceramic fiber heat insulation pad includes the following steps:

[0041] S1, select aluminum silicate fibers; select aluminum silicate fibers with an aluminum content of 45-55%, a fiber diameter of 2-5μm, a specific gram value of 400-800ml, a fiber length of 2-50mm, and a fiber toughness of 300-600ml ;

[0042] S2, mixing aluminum silicate fiber and water for stirring and pulping, wherein the proportion of aluminum silicate fiber is not less than 3%, the stirring speed is 0-350r / min, the stirring time is 0-10min, until the fiber is in the slurry The specific gram value is not less than 300ml, the fiber content has not changed, and the product has a good dispersion effect. The blades of the mixing blade need to be treated during mixing and pulping, and the mixing head is replaced by a common propeller type and a multi-layer type to a combination of the two. The blade is converted from multiple layers to one layer, the blade blades are blunt, and th...

Embodiment 1

[0048] The ceramic fiber heat insulation pad is made of the following mass percentages of raw materials: 92% aluminum silicate fiber raw cotton, 7% organic binder, and 1% auxiliary agent.

[0049] This scheme uses ordinary aluminum silicate fiber, that is, the alumina content of the fiber raw cotton component is 45%, and the fiber is soft and tough. The specific gram value of raw cotton is 500ml. The organic binder is a water-based acrylic resin.

[0050] The auxiliary agent used in this scheme is silicate. The addition of such additives can effectively disperse the fiber, reduce the surface charge, make the fiber soft, and improve the retention of the organic binder in the fiber.

[0051] The preparation process is as follows: first weigh the aluminum silicate fiber cotton at a concentration of 3% (mix 3% aluminum silicate fiber with 97% water), and then place the aluminum silicate fiber and water in a mixing tank. Stir at a speed of 300r / min for 10 minutes to configure a uniform...

Embodiment 2

[0059] The ceramic fiber heat insulation pad is made of the following mass percentages of raw materials: 95% aluminum silicate fiber raw cotton, 4% organic binder, and 1% additive.

[0060] This scheme uses ordinary aluminum silicate fiber, that is, the alumina content of the fiber raw cotton component is 50%, and the fiber is soft and tough.

[0061] The organic binder is a water-based polyurethane resin.

[0062] The auxiliary agent used in this scheme is alkali metal phosphate. Additives added to the product can effectively disperse the fiber, reduce the surface charge, make the fiber soft, and improve the retention of glue in the fiber.

[0063] Preparation process: first weigh the aluminum silicate fiber cotton at a concentration of 3%, then place the aluminum silicate fiber cotton in a mixing tank and stir at 200r / min for 10 minutes to configure to 0.2% or 1% or 2% or 3% uniform slurry, so that the fiber ratio in the slurry is 400ml or 450ml or 500ml.

[0064] When forming, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com