Refrigeration constant temperature control method and incubator

A constant temperature control, incubator technology, applied in biochemical equipment and methods, tissue cell/virus culture devices, biochemical instruments, etc. Reduce energy consumption, improve service life and temperature control effect, and provide the effect of market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

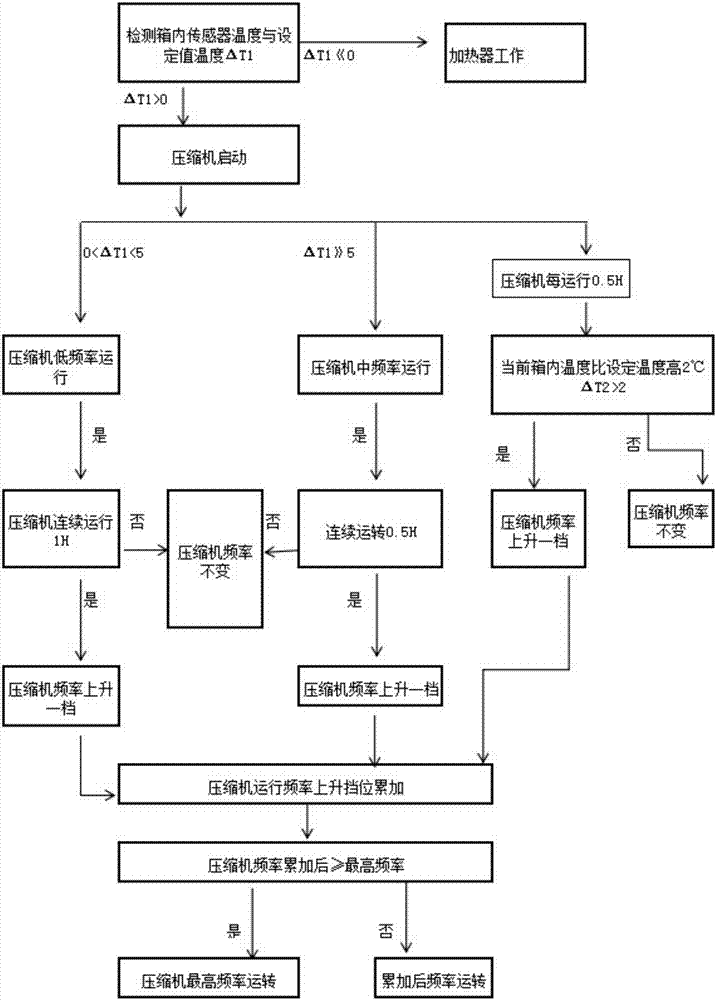

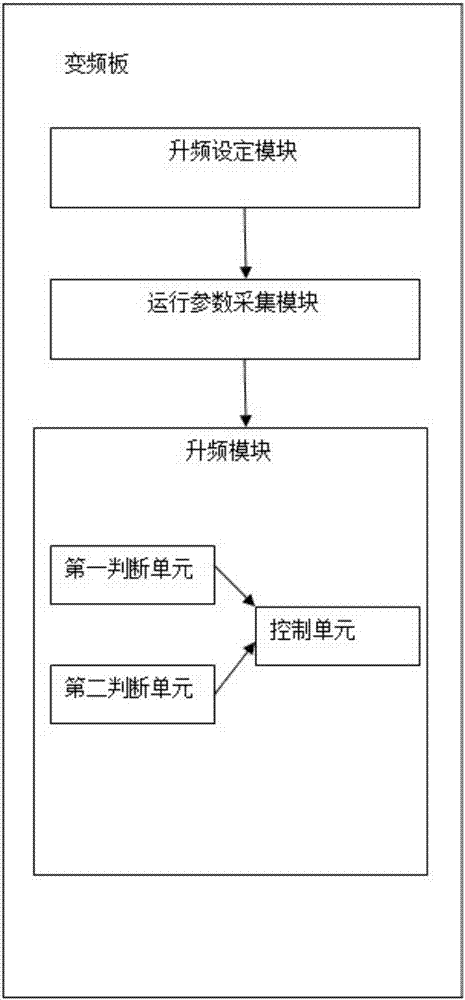

[0057] Please refer to figure 1 , figure 1 It is a block flow diagram of a refrigeration constant temperature control method of the present invention. A refrigeration constant temperature control method, said method comprising the following steps:

[0058] Step S1: Detect the temperature in the incubator and the set temperature value before the operation of the inverter compressor;

[0059] Step S2: setting the frequency conversion condition of the frequency conversion compressor 7;

[0060] Step S3: After the frequency conversion compressor 7 is started, the operating parameters in the incubator are collected;

[0061] Step S4: According to the operating parameters of the incubator 1 and the frequency conversion conditions, it is judged whether to adjust the frequency of the frequency conversion compressor, and the frequency conversion compressor 7 is controlled according to the result.

[0062] In step S1, the difference ΔT1 between the temperature in the box and the set...

Embodiment 2

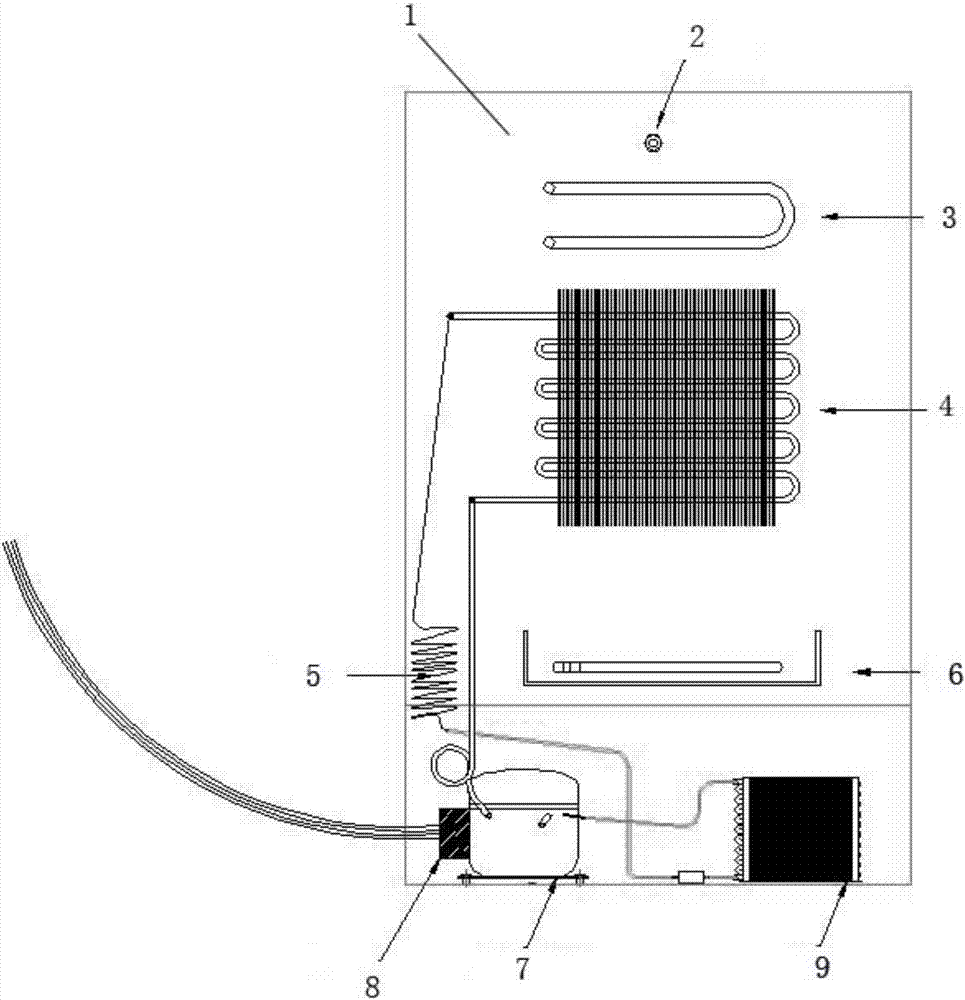

[0075] Please refer to figure 2 , figure 2 It is a structural schematic diagram of a refrigerated and constant temperature incubator of the present invention. An incubator with refrigeration and constant temperature, the incubator includes a box body 1, a sensor 2, a heater 3, an evaporator 4, a humidifier 6, a condenser 9, a capillary tube 5, a frequency conversion compressor 7, and a frequency conversion board 8; The sensor 2 described above is arranged inside the box body 1; a heater 3 is arranged below the sensor 2, the heater 3 is U-shaped, and an evaporator 4 is arranged below the heater 3; the evaporator 4 has two leads One end of the evaporator 4 is connected to the capillary 5, and the other end of the capillary 5 is connected to the condenser 9, and the other end of the evaporator 4 is connected to the frequency conversion compressor 7; There is a frequency conversion board 8, and the other side of the frequency conversion compressor 7 is connected to the condens...

Embodiment 3

[0079] Please refer to Figure 4 with Figure 5 , a refrigerated and constant temperature incubator, the incubator also includes an inner tank 10, an outer door 11, a control box panel 13, an upper air channel plate 14 on the inner tank, a fan 15, a screen spacer 16, and a rear cover of the cabinet Plate 17, protective cover 18, liner lower air channel plate 19, casters 20, rear protective cover 21, foam plastic board 22; the top of the box body 1 is provided with a control box 12, and the outside of the control box 12 is provided with a control box face plate 13; The outer door 11 is provided on the lower box body 1 of the control box panel 13;

[0080] A protective cover 18 is installed at the bottom of the casing 1; a condenser 9 and a variable frequency compressor 7 are installed in the protective cover 18, and a rear protective cover 21 is provided on the outer side of the protective cover 18 on one side of the variable frequency compressor 7; The upper edge of the prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com