Novel spinneret plate for wet spinning non-woven fabric

A non-woven fabric, wet spinning technology, used in textiles and papermaking, spinneret assemblies, etc., can solve the problems of high cost, uneven inner and outer strength of fibers, unable to ensure sufficient response, etc., to ensure consistent thickness , Save production costs, the effect of consistent quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

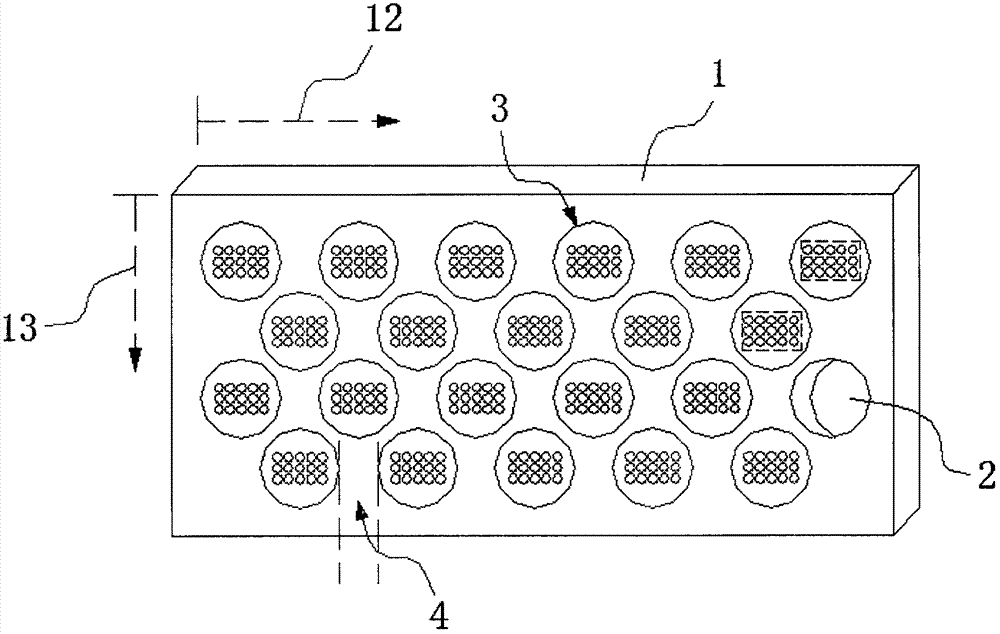

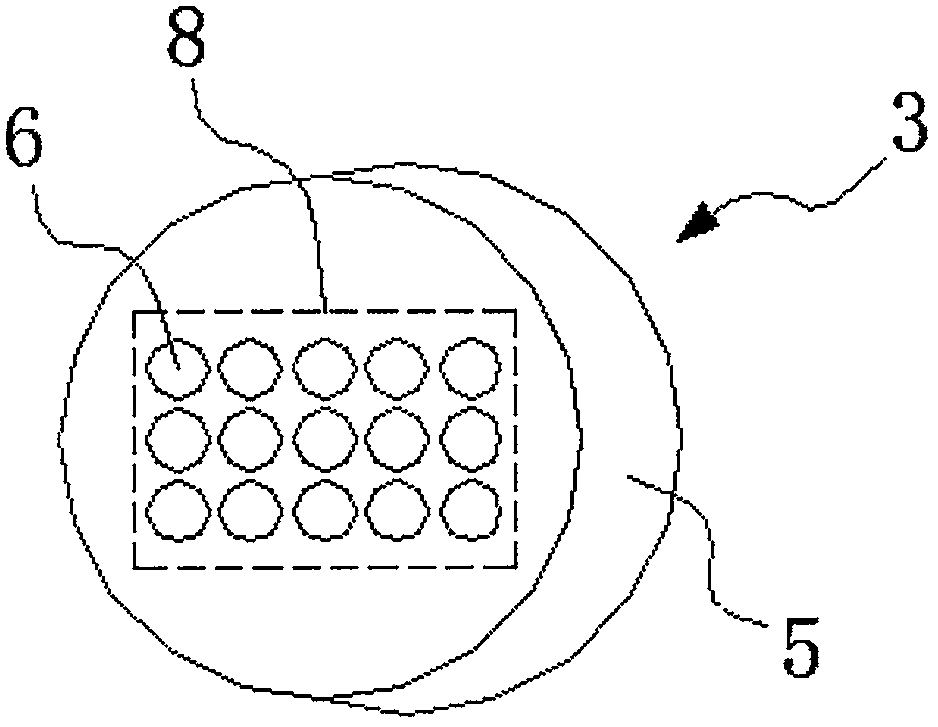

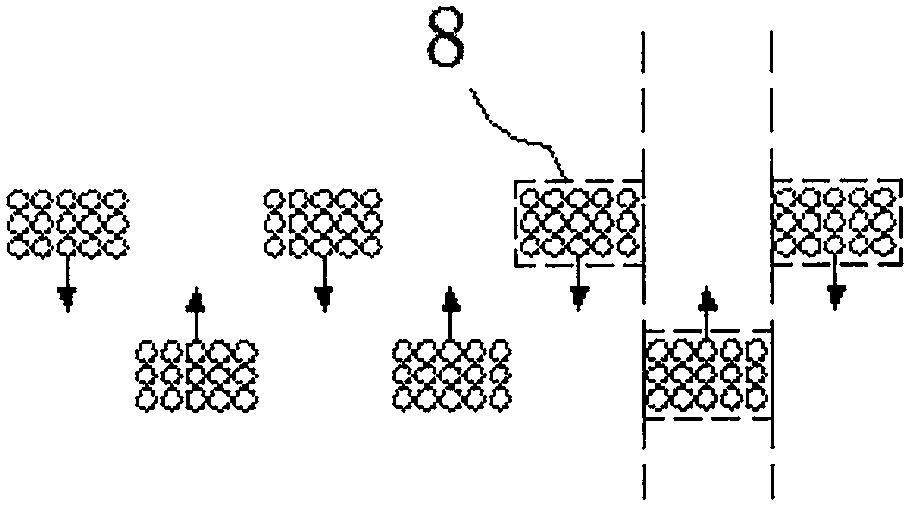

[0023] Such as figure 1 , 2 , 3, and 4, a novel spinneret for wet spinning nonwovens, including a base plate 1, in order to obtain sheet-like tow, it is best that the base plate 1 is arranged as a rectangular plate structure, and the base plate 1 Choose to use metals such as tantalum, iridium, titanium, niobium and other metals with strong corrosion resistance. There are multiple sets of mounting holes 2 provided on the base plate 1, and spinneret units 3 are respectively installed in each mounting hole 2, and auxiliary coagulation bath liquid and spinning liquid are reserved between adjacent spinneret units 3. The reaction zone 4 in contact, the spinneret unit 3 includes a spinneret body 5 adapted to the installation hole 2, for ease of processing and installation, the cross-sectional shape of the installation hole 2 and the spinneret body 5 is set to Round shape, with a plurality of spinneret holes 6 that allow the spinning solution to be sprayed out on the spinneret body ...

Embodiment 2

[0026] The same parts of this embodiment and Embodiment 1 will not be repeated, and the difference is that: Figure 5 As shown, the bottom plate 14 can also be set to a circular plate structure, and the cross-sectional shape of the installation hole and the spinneret body can also be set to a rectangle, but the layout of the spinneret holes still needs to be arranged in a rectangular shape, so that the upper and lower rectangles When the spinneret units are stacked, they can be connected left and right, and the number of upper and lower tows is the same. As long as it is ensured that the tow can be stacked up and down, the thickness of the formed sheet-like tow is uniform everywhere. Such as Image 6 , 7 As shown, the spinneret body 15 includes a front rotor 17 with a spinneret hole 16 and a rear rotor 18 connected to the front rotor 17. The junction of the front rotor 17 and the rear rotor 18 Bosses 19 are provided, and a spinning solution accommodating cavity 20 communica...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap