Energy storage device capable of factory production for energy storage and power generation

An energy storage device and technology for energy storage and power generation, which are applied in wind power generation, sustainable manufacturing/processing, and wind engines for storing kinetic energy, etc., can solve the problems of low energy conversion rate and long energy storage time, and achieve wide adaptability, Effects of low cost and expanded scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

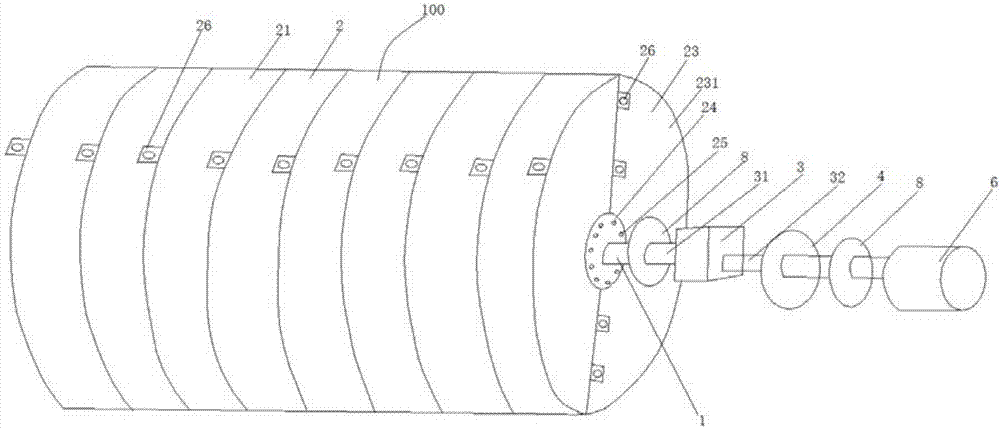

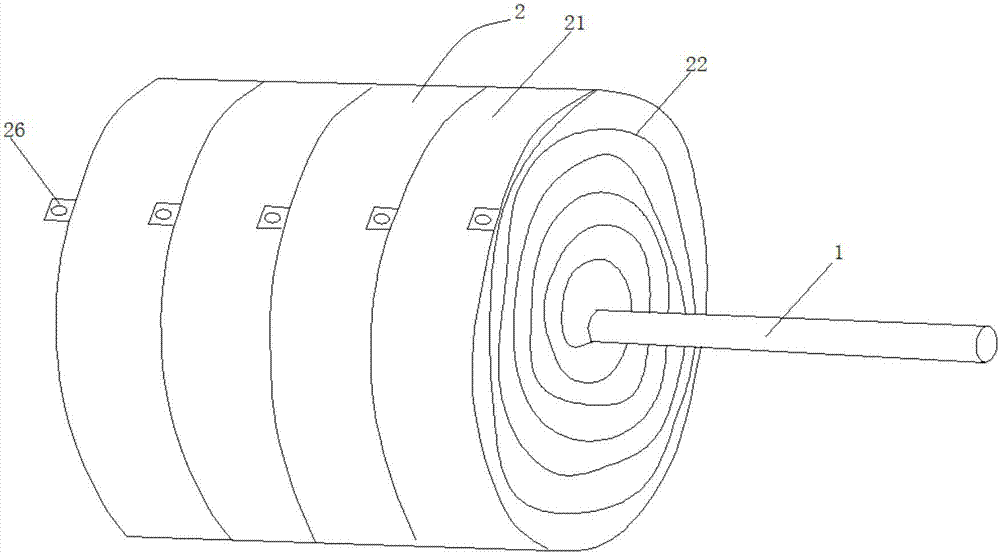

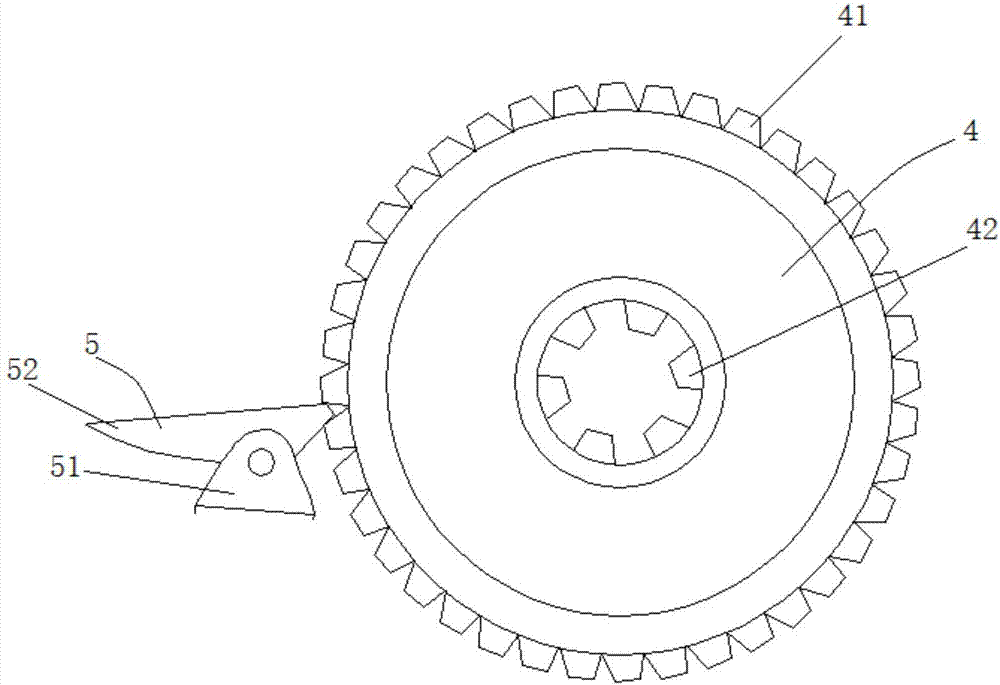

[0044] see Figure 1-5 , the present invention provides an energy storage device capable of industrialized energy storage and power generation. The energy storage device includes: a shaft 1; several energy storage units 2, each of which includes an annular casing 21 and an end The energy storage spring 22 connected in the annular casing 21, the energy storage unit 2 is sleeved on the shaft 1 through the other end of the energy storage spring 22 and forms a detachable connection with the shaft 1. The energy units 2 are sequentially arranged along the length direction of the shaft 1 to form a cylindrical energy storage body 100, one end of the shaft 1 protrudes to the outside of the energy storage body 100; a gear box 3, the output shaft 31 and the shaft The rod 1 extends out of the outer end of the energy storage main body 100 and is connected; a brake gear 4 is sleeved on the input shaft 32 of the gearbox 3; The support 51 and the detent 52 rotatably arranged on the support 51,...

Embodiment 2

[0061] A detachable connection is formed between the shaft 1 and the energy storage spring 22 via screws (not shown). All the other are with embodiment 1.

Embodiment 3

[0063] see Figure 4 , the surface of the input shaft 32 of the gearbox 3 located on both sides of the brake gear 4 is respectively provided with fixing grooves (not shown), and the two circular fixing parts 9 are sleeved on the input shaft 32 and clamped in the fixing grooves to form The fixing of the brake gear 4 on the input shaft 32 of the gear box 3, the two fixing parts 9 respectively include two symmetrically arranged semicircular fixing rings 91 matched with the input shaft 32 of the gear box 3, and the two ends of the fixing ring 91 Respectively extending outwards to form two fixing parts 92, fixing through holes 93 are provided on the fixing parts 92, the fixing parts 92 of the two fixing rings 91 are butted, the fixing parts 92 of the two fixing rings 91 are butting, the fixing through holes 93 on the adjacent two fixing parts 92 In communication, the two fixing rods 94 are respectively inserted into the two communicating fixing through holes 93 to form the fixing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com