Multi-section heating multi-section tempering and drying airflow closed cycle heat pump drying system

A multi-stage heating and closed-circuit technology, applied in drying, heat pump, dryer and other directions, can solve the problems of poor economical efficiency of heat pump units, reduced biological activity of grains, and reduced heating energy efficiency ratio, so as to improve heating power. and heating energy efficiency ratio, improve drying production intensity, and improve the effect of heating energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

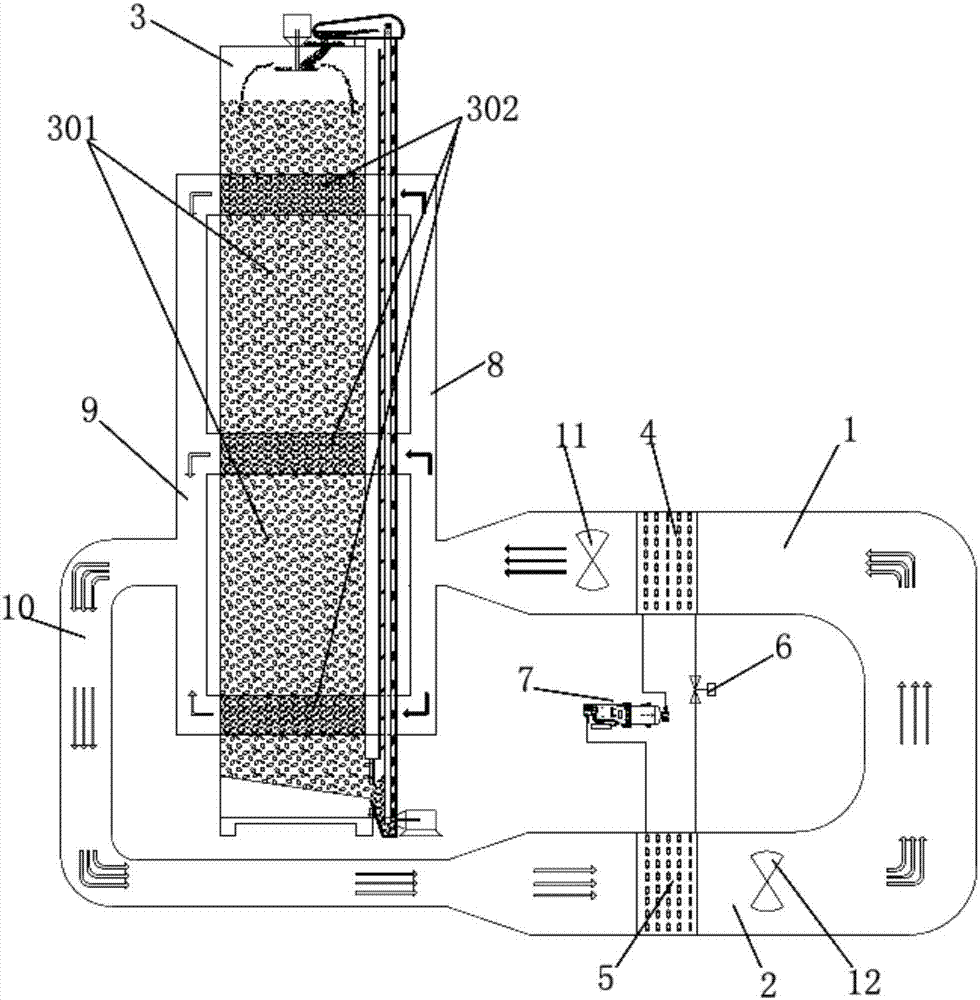

[0062] refer to Figure 1-3 , in this embodiment, the drying part includes a drying room 3, of course, in other embodiments, the drying part may also include a plurality of drying rooms, which is not limited here.

[0063] In this example, refer to figure 1 , the drying room is a drying tower structure, and a hoist is arranged on the right side to continuously transport the dried objects at the bottom of the drying tower to the top of the drying tower, so that the dried objects move down from the top of the drying tower to the bottom of the drying tower. At the bottom, repeat this cycle until it is dried by the dry object.

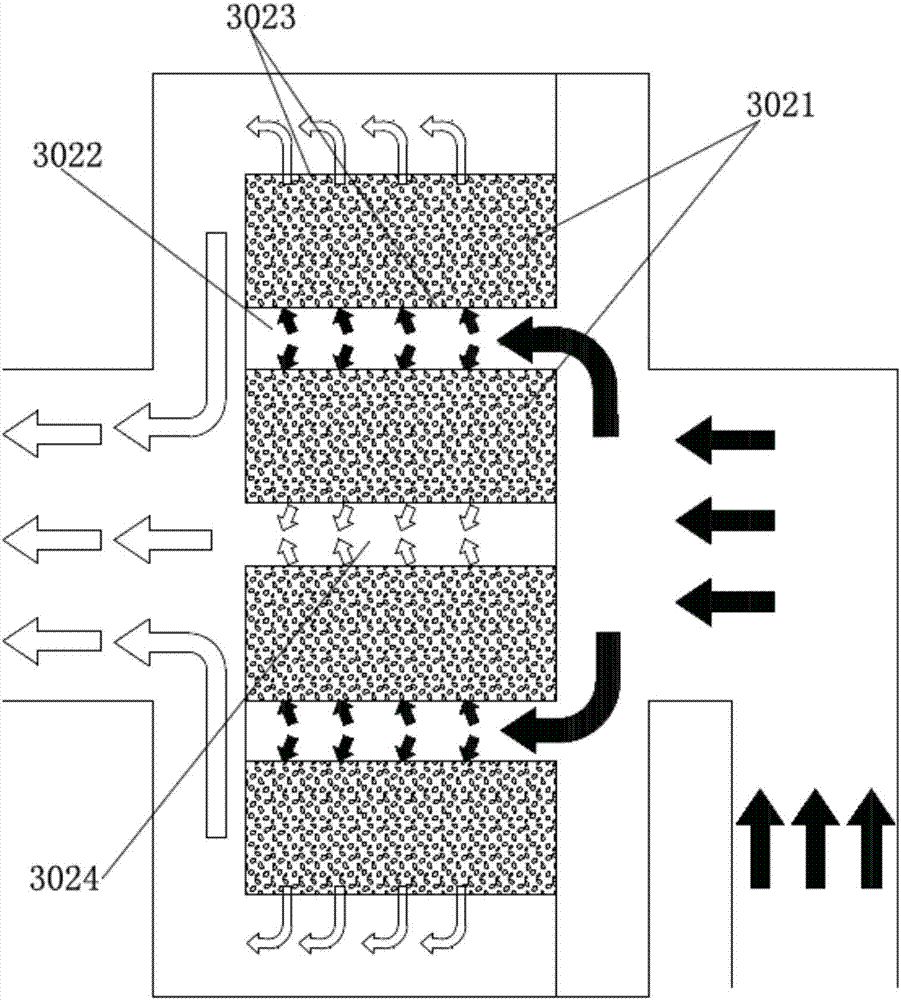

[0064] Among them, three drying sections 302 are arranged from top to bottom in the drying tower, and the three drying sections 302 are arranged at intervals, and the drying tower part between adjacent drying sections 302 forms a slow recovery section 301; In the cycle, after the object to be dried passes through the uppermost drying section, the moistur...

Embodiment 2

[0079] This embodiment is an improvement made on the basis of Embodiment 1.

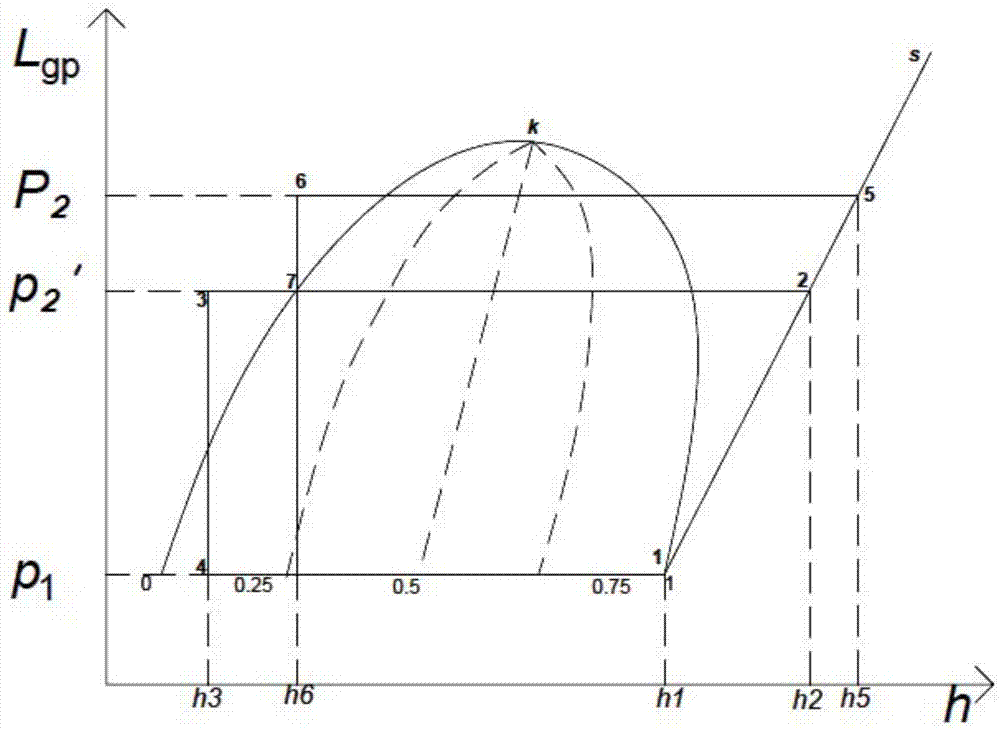

[0080] In this embodiment, the heat pump system includes at least two sets of heat pump units, and each set of heat pump units includes a connected compressor, condenser, throttle valve and evaporator; the condensers are all arranged in the inflow channel, and at least one evaporator The condenser is arranged in the outflow channel; wherein, the condensers in the heat pump unit are arranged sequentially from the inlet of the inflow channel to the drying room, and each set of corresponding evaporators located in the outflow channel starts from the outlet of the outflow channel to the drying room. Arrange the settings in sequence.

[0081] In this embodiment, the traditional one-step large temperature difference and high power heat pump waste heat recovery is transformed into a multi-step and multi-step small temperature difference heat pump waste heat recovery, so that the fluid medium carrying waste ...

Embodiment 3

[0101] This embodiment implements the improvements made on the basis of Embodiment 1 or Embodiment 2.

[0102] In this embodiment, the drying part includes two or more drying rooms connected in parallel, and the drying medium coming from the inflow channel 1 is distributed to each drying room for drying, and after drying, it is collected and discharged from the outflow channel 2 .

[0103] The drying system provided in this embodiment adopts the "one-to-many" operation mode in which a large-scale heat pump unit drives multiple dryers at the same time, which is in line with the industrialization and commercialization of grain drying and the development trend of large-scale automation of grain dryers, and It saves a lot of fans, electric control boxes, dust removal and filtration equipment, etc., while reducing investment, it also improves the operating efficiency of the equipment.

[0104] Specifically, refer to Figure 6 , in this embodiment, the drying part includes 5 parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com